Fireproof coating for building

A fire-resistant coating and coating technology, applied in fire-resistant coatings, cement coatings, etc., can solve the problems of fire resistance, strength, water resistance, acid resistance, and heat and humidity resistance that cannot fully meet the fire protection requirements of buildings, and achieve strong adhesion, The effect of reducing dry density and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the preparation of formula I compound

[0022] In a 500 ml single-necked flask, o-cresol (15 g, 138.7 mmol), sodium thiocyanate (34 g, 419.3 mmol), sodium bromide (16 g, 155.5 mmol) were successively weighed, and 200 ml Methanol was stirred, cooled to 0°C, and liquid bromine (8.6 ml, 167 mmol) diluted with 30 ml of methanol was added dropwise. After the addition was complete, the reaction was incubated for 1 hour, then naturally rose to room temperature, and the reaction was continued for 4 hours. After the reaction, add 200 ml of saturated aqueous sodium bicarbonate solution, stir for 10 minutes, extract with ethyl acetate (2×500 ml), combine the organic phases, dry over anhydrous magnesium sulfate, filter, and concentrate under reduced pressure to obtain a yellow gum . Column chromatography (silica gel H: 300-400 mesh; petroleum ether / ethyl acetate=8:1) gave 16 g of 3-methyl-4-hydroxy-phenylthiocyanic acid (white solid, yield: 69.8%).

[0023] In a 500...

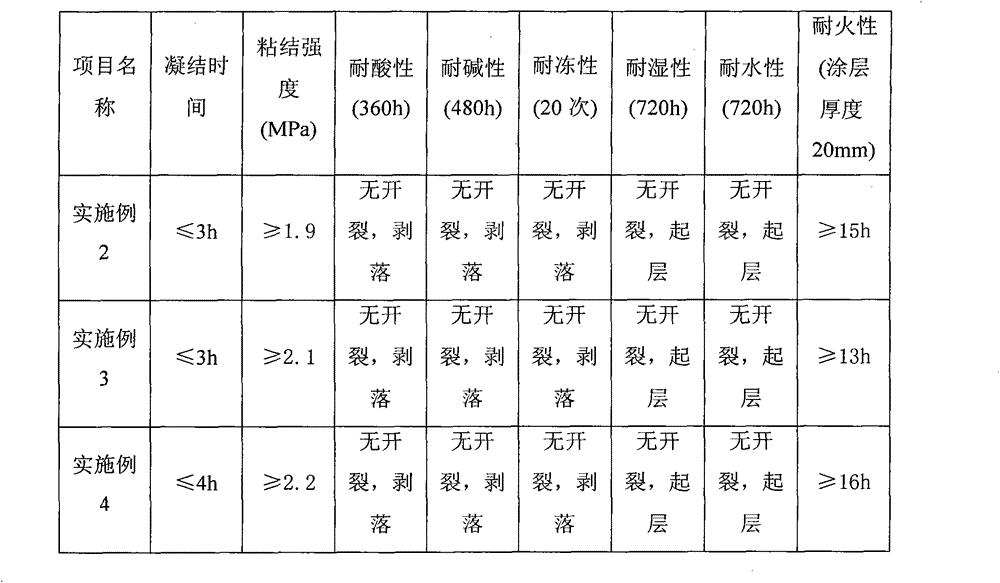

Embodiment 2

[0027] 25 parts by weight of Portland cement, 17 parts by weight of ammonium dichromate, 6 parts by weight of light calcium carbonate, 2 parts by weight of aluminum silicate, 7 parts by weight of fly ash hollow beads, 6 parts by weight of One part of wollastonite powder and 0.2 part by weight of the compound of formula I were put into a V-shaped forced mixer, started and stirred for 15 minutes to form a powdery mixture. Take water as needed and the above-mentioned fireproof coating powder in a weight ratio of 0.8, and stir to form a thick slurry-like waterproof coating for buildings.

Embodiment 3

[0029] The Portland cement of 29 parts by weight, the ammonium dichromate of 20 parts by weight, the light calcium carbonate of 8 parts by weight, the aluminum silicate of 2 parts by weight, the fly ash hollow floating beads of 70 parts by weight, 7 parts by weight One part of wollastonite powder and 0.25 part by weight of the compound of formula I were put into a V-shaped forced mixer, started and stirred for 12 minutes to form a powdery mixture. Take water as needed and the above-mentioned fireproof coating powder in a weight ratio of 0.8, and stir to form a thick slurry-like waterproof coating for buildings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com