Preparation method of high-temperature-resistant reinforced and toughened Ox/Ox composite material

A composite material, strengthening and toughening technology, which is used in the preparation of high temperature resistant reinforced and toughened alumina fiber reinforced alumina matrix composite materials, and the preparation of high temperature resistant reinforced and toughened Ox/Ox composite materials, which can solve the problem of fiber debonding, The problems of pulling out, incomplete sintering of the substrate, poor mechanical properties, etc., achieve the effects of high strength and high hardness, uniform nanowire coating, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

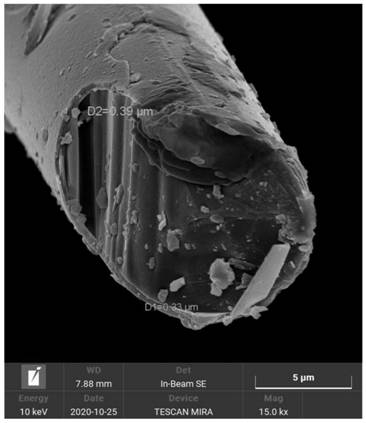

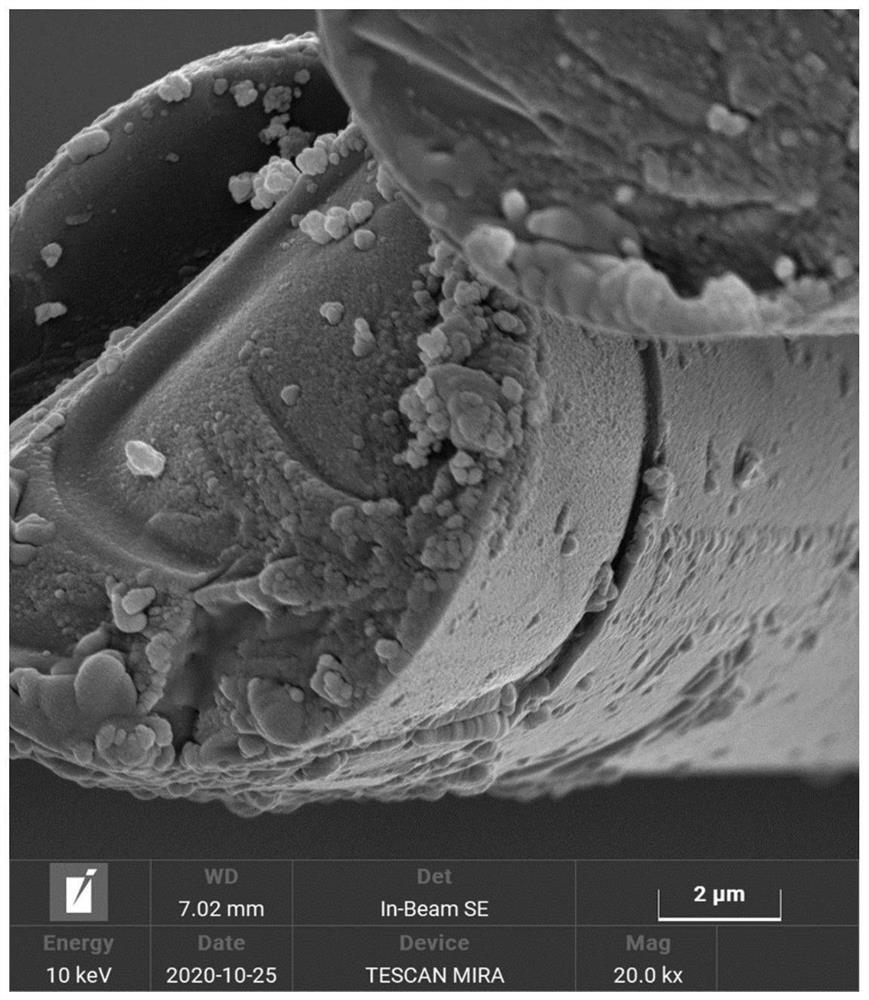

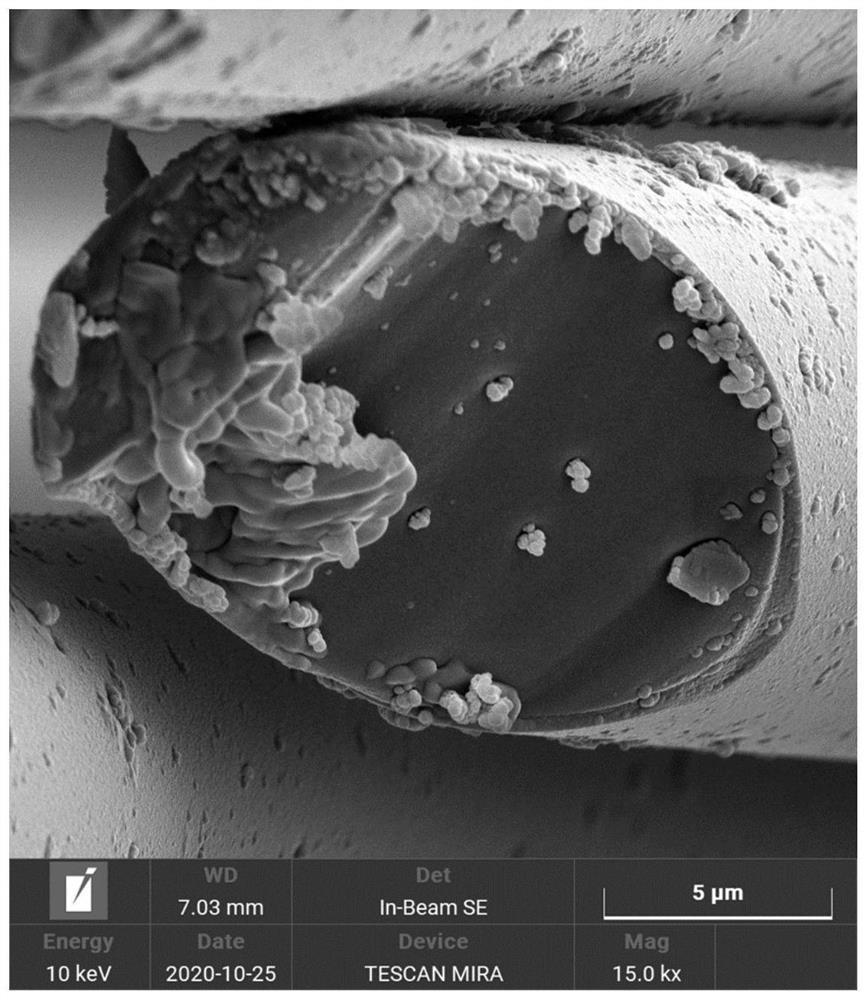

[0044] The high-temperature-resistant reinforced and toughened Ox / Ox composite material provided in the present invention is a kind of high-temperature-resistant reinforced and toughened alumina fiber-reinforced alumina matrix composite material, and its preparation method specifically includes the following steps:

[0045] S1. Pretreatment of alumina fibers:

[0046] According to actual needs, place alumina fibers of required size in the pretreatment solution for vacuum impregnation, place the impregnated alumina fibers in a high-temperature furnace for heat treatment, and then repeat the above pretreatment solution impregnation-heat treatment for alumina fibers The process is to obtain an alumina fiber with a surface coating of 10-500 nm, and then perform a pretreatment solution immersion-heat treatment process.

[0047] S2. Preparation of composite nanowire coating:

[0048] Put the alumina fiber coated on the above surface into a vapor deposition furnace, deposit pyrolyti...

Embodiment 1

[0057] Two-dimensional plain weave alumina fibers are placed in a mixed solution of 30vol% ammonium dichromate and anhydrous oxalic acid for vacuum impregnation, wherein the concentration of anhydrous oxalic acid in ammonium dichromate is 200g / mL, Immerse for 4 hours. After the impregnation is completed, the alumina fiber is heat-treated in a high-temperature furnace. The temperature of the heat treatment process is 300°C, and then the alumina fiber is placed in a mixed solution of 30vol% ammonium dichromate and anhydrous oxalic acid for vacuum impregnation. 4h, after the impregnation is completed, put it into a high-temperature furnace at 300°C for heat treatment to obtain alumina fibers with a surface coating of 10nm, and then repeat the mixed solution immersion-heat treatment process once. Wherein, the two-dimensional plain weave has 10-16 strands of warp yarn or weft yarn per 1 cm.

[0058] Put the alumina fiber with 10nm coating on the above surface into a vapor depositio...

Embodiment 2

[0063] Vacuum-impregnate the alumina fibers of the three-dimensional stitching felt in a mixed solution of ammonium dichromate and anhydrous oxalic acid at a concentration of 50vol%, wherein the concentration of anhydrous oxalic acid in ammonium dichromate is 10g / mL, and the impregnation 2h, after the impregnation is completed, the alumina fiber is heat-treated in a high-temperature furnace at a temperature of 100°C, and then the above-mentioned mixed solution immersion-heat treatment process is repeated for the alumina fiber 4 times to obtain an alumina fiber with a surface coating of 500nm. The mixed solution immersion-heat treatment process was repeated once. Wherein, the warp yarn or weft yarn per 1 cm of the three-dimensional sewing felt is 4 to 20 strands.

[0064] Put the aluminum oxide fiber with a surface coating of 500nm into a vapor deposition furnace (CVI), deposit a 150nm BN pre-coating on the surface of the coating, and then use the electric pulse deposition meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com