Production method of high-grade pigment chromium oxide green

A chromium oxide green and production method technology, applied in the field of metallurgy and chemical industry, can solve the problems of inconvenient industrial feeding, inability to realize large-scale industrial production, high moisture content of materials, etc., and achieve benefits for large-scale industrial production, broad market prospects and profits The effect of simple space and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

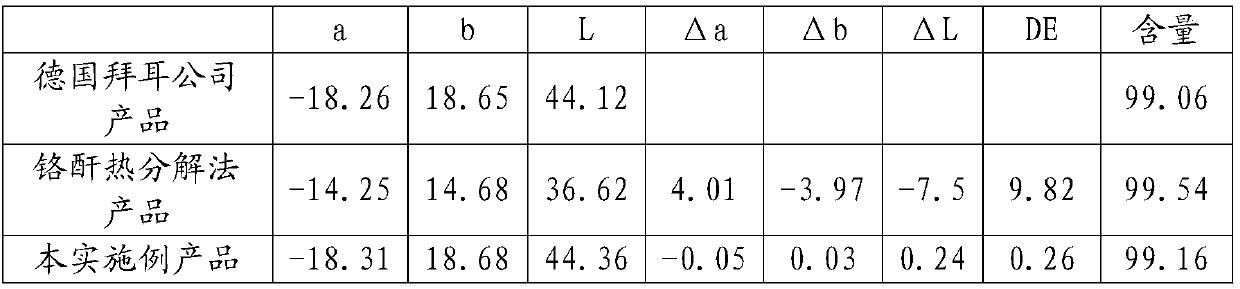

Embodiment 1

[0025] A kind of production method of high-end pigment chromium oxide green in the present embodiment comprises the following steps:

[0026] S1. Dissolve 1 ton of sodium dichromate and 0.35 ton of ammonium sulfate to 2m at 20°C 3 In tap water, stir and dissolve to form a saturated mother liquor;

[0027] S2. Raise the temperature of the saturated mother liquor obtained in step S1 to 90° C., and form an unsaturated mother liquor as the temperature rises, and add 1 ton of sodium dichromate and 0.35 tons of industrial ammonium sulfate again under stirring, and stir for 30 minutes;

[0028] S3. Turn on the cooling and cooling device, and re-cool the material finally obtained in step S2 to 20°C. With the cooling of the temperature, the solubility of the material decreases again, and crystals are precipitated in the saturated mother liquor to form a crystalline material;

[0029] S4. Put the crystalline material formed in step S3 into a centrifuge for crystallization and separatio...

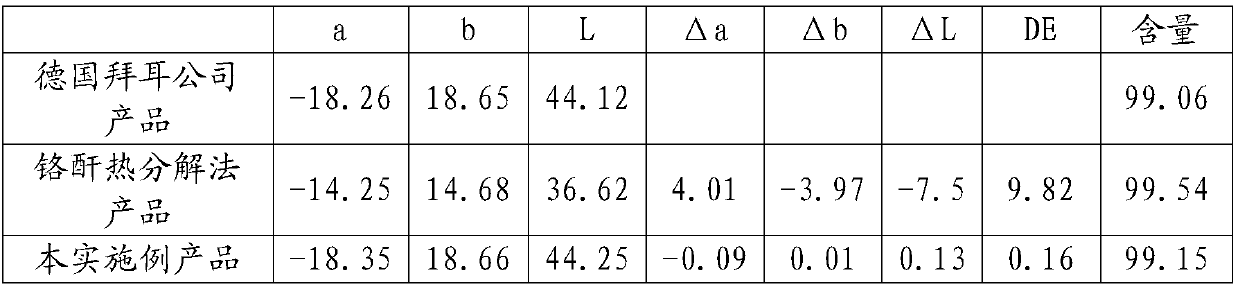

Embodiment 2

[0036] A kind of production method of high-end pigment chromium oxide green in the present embodiment comprises the following steps:

[0037] S1, re-enter the mother liquor recovered in Example 1 into the reaction vessel, at this moment, the mother liquor is still the material-saturated mother liquor at 20°C;

[0038] S2. The temperature of the saturated mother liquor of the material is raised to 90°C, and an unsaturated mother liquor is formed as the temperature rises, and 1 ton of sodium dichromate and 0.35 tons of industrial ammonium sulfate are added again under stirring, and the reaction is stirred for 30 minutes;

[0039] S3. Turn on the cooling and cooling device, and re-cool the material finally obtained in step S2 to 20°C. With the cooling of the temperature, the solubility of the material decreases again, and crystals are precipitated in the saturated mother liquor to form a crystalline material;

[0040] S4. Put the crystalline material formed in step S3 into a cent...

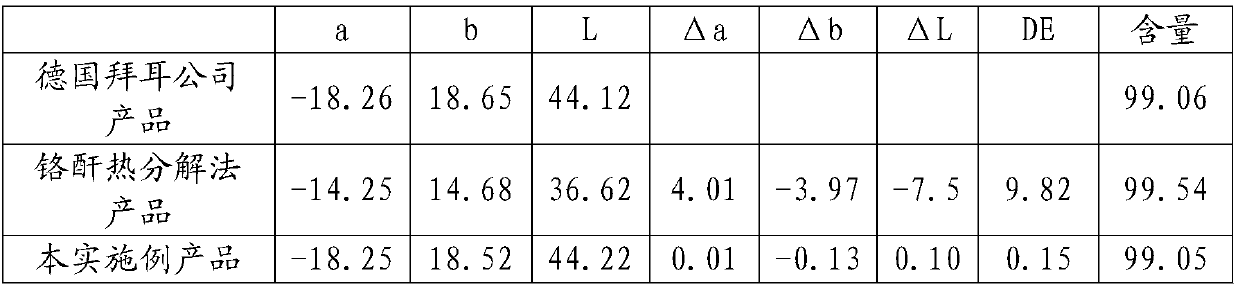

Embodiment 3

[0049] A kind of production method of high-end pigment chromium oxide green in the present embodiment comprises the following steps:

[0050] S1. Dissolve 1 ton of sodium dichromate and 0.25 ton of ammonium carbonate at 20°C to 2m 3In tap water, stir and dissolve to form a saturated mother liquor;

[0051] S2. The temperature of the saturated mother liquor obtained in step S1 is raised to 90°C, and an unsaturated mother liquor is formed as the temperature rises, and 1 ton of sodium dichromate and 0.25 tons of industrial ammonium carbonate are added under stirring again, and the reaction is stirred for 30 minutes;

[0052] S3. Turn on the cooling and cooling device, and re-cool the material finally obtained in step S2 to 20°C. With the cooling of the temperature, the solubility of the material decreases again, and crystals are precipitated in the saturated mother liquor to form a crystalline material;

[0053] S4. Put the crystalline material formed in step S3 into a centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com