Coated cutting tool and preparation method thereof

A cutting tool and coating technology, applied in turning equipment, manufacturing tools, turning equipment, etc., can solve the problems of poor coating adhesion and wear resistance, cumbersome preparation process, unfavorable mass production, etc., and achieve excellent coating layer adhesion, improved adhesion, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

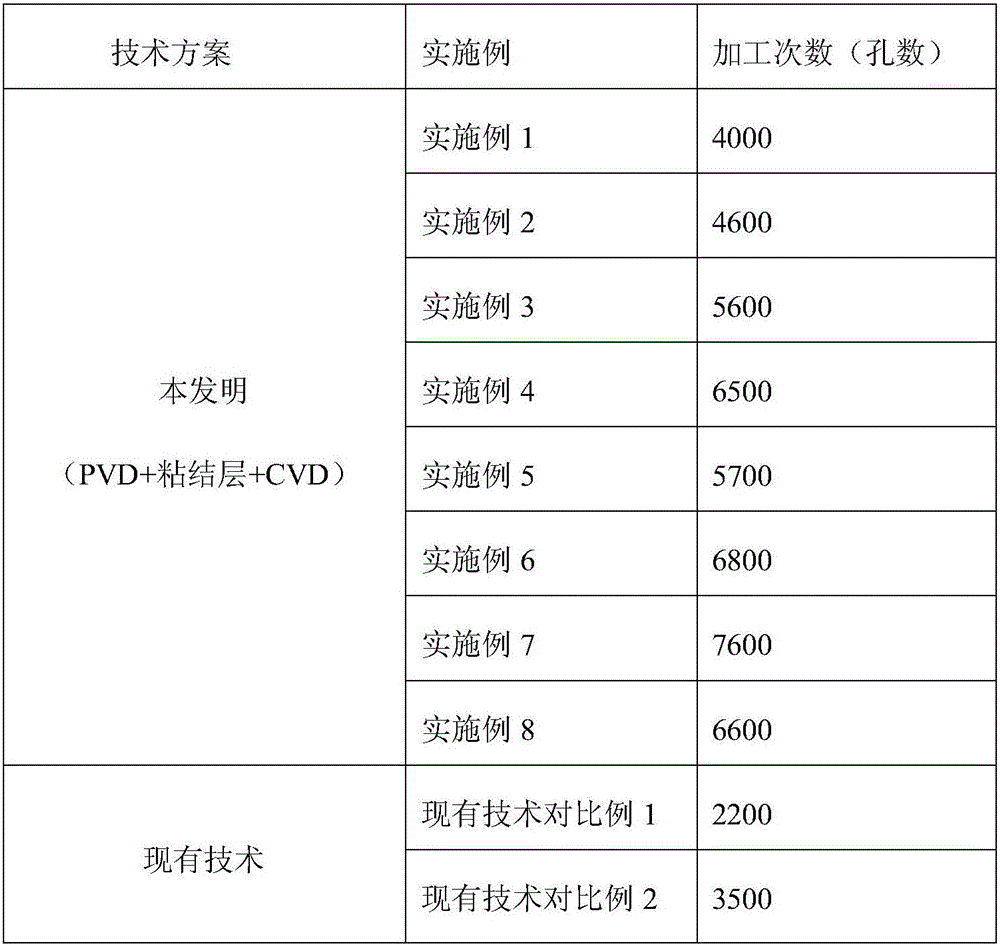

Examples

Embodiment 1

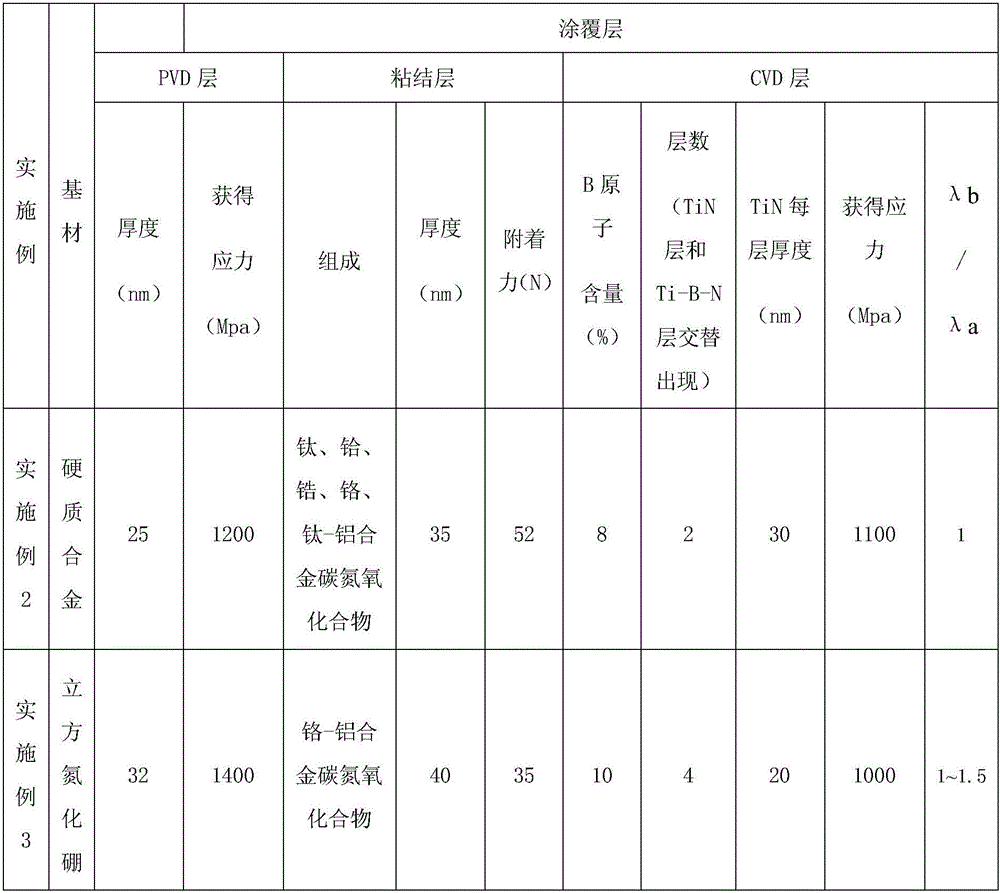

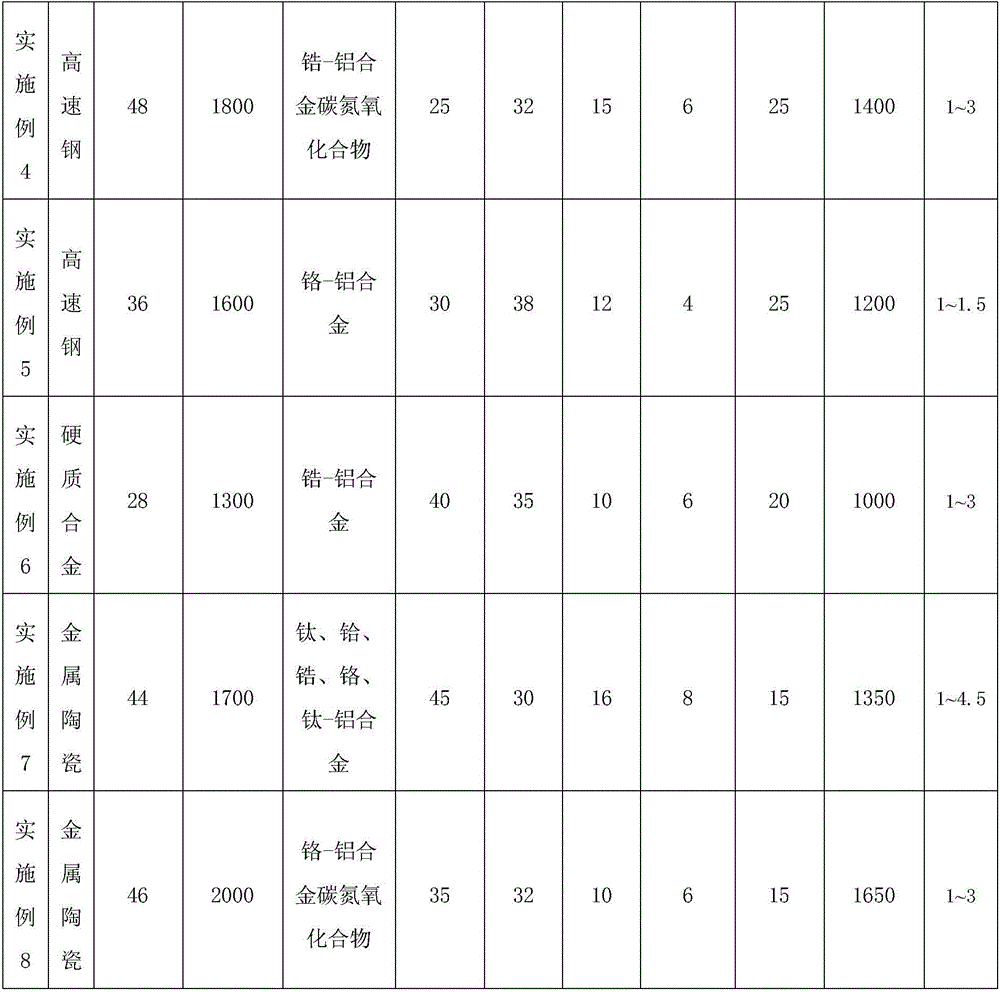

[0027] A kind of coating cutting tool, choose cermet as base material, coating layer comprises inner layer PVD layer and outer layer CVD layer, CVD layer is a layer of TiN layer and a layer of Ti-B-N, the B in Ti-B-N layer The content is 9at%. The addition of B atoms will form boron oxides formed by surface oxidation during the cutting process. Due to its low melting point, it can be used as a lubricant to inhibit the adhesion of cut materials. The bonding layer between the PVD layer and the CVD layer is a hafnium-aluminum alloy carbonitride, the thickness of the single-layer structure of the TiN layer is 15nm, λb / λa=1, the stress ratio between the PVD layer and the CVD layer is 1.2, and the coating The total layer thickness is 80 nm.

[0028] A method for preparing a coated cutting tool, the method comprising the steps of:

[0029] (1) Select cermet as the base material and clean it; put the cemented carbide into the cathodic arc ion plating equipment, and clean the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com