Urethanation modified hybrid phenolic resin and preparation method thereof

A technology of novolac resin and phenolic resin, which is applied in the field of urethane-modified hybrid phenolic resin for heat-sensitive CTP plates and its preparation, which can solve the problem of poor solvent resistance and printing resistance of heat-sensitive plates, resin and plate The impact of alkali solubility of materials and other issues, to achieve the effect of improving the printing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

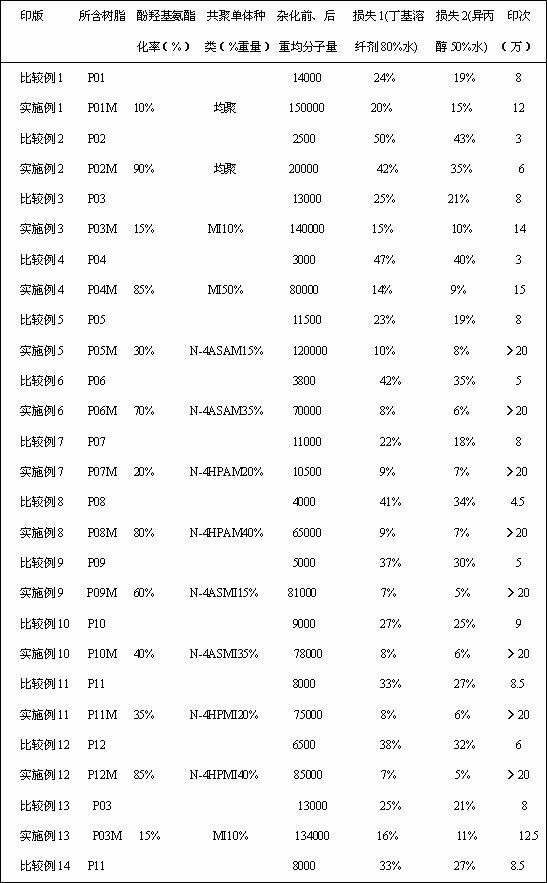

[0075] Example 1 (phenolic resin P01, modified phenolic resin P01M)

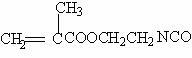

[0076] Add 565.7 g of DMAC (N, N-dimethylacetamide) and 200.0 g of phenolic resin to a 1000 ml four-necked flask with temperature-controlled heating, mechanical stirring, reflux and nitrogen protection device P01 (commodity code: MV4020G, m / p=60 / 40, Mw≈14000), heated and stirred at 60°C under nitrogen atmosphere until the solid was dissolved, then added 1.0g of dibutyltin dilaurate, and then slowly added 26.3g of MOI (methacryloyl Oxyethyl isocyanate) was reacted for 4 hours until the peak at 2275 of the active isocyanate group detected by infrared spectroscopy disappeared.

[0077] 1.2 g of AIBN (azobisisobutyronitrile) was added to the above reaction solution, and the reaction was completed after 23 hours at 70°C. The reactant was precipitated in deionized water, washed, and vacuum-dried at 40°C to obtain homopolymerized modified phenolic resin P01M. See the following table for performance.

Embodiment 2

[0078] Example 2 (phenolic resin P02, modified phenolic resin P02M)

[0079] Add 1091 g of DMAC (N, N-dimethylacetamide) and 200.0 g of phenolic resin to a 1500 ml four-necked flask with temperature-controlled heating, mechanical stirring, reflux and nitrogen protection device P02 (commodity code: EPR6040A, m / p=40 / 60, Mw≈2500), heated and stirred at 60°C under nitrogen protection until the solid dissolved, then added 1.0g of dibutyltin dilaurate, and then slowly added 236.4g of MOI (methacryloyl Oxyethyl isocyanate) was reacted for 4 hours until the peak at 2275 of the active isocyanate group detected by infrared spectroscopy disappeared.

[0080] 2.2 g of AIBN (azobisisobutyronitrile) was added to the above reaction liquid, and the reaction was completed after 23 hours at 70°C. The reactants were precipitated in deionized water, washed, and vacuum-dried at 40°C to obtain homopolymerized modified phenolic resin P02M. See the following table for performance.

Embodiment 3

[0081] Example 3 (phenolic resin P03, modified phenolic resin P03M)

[0082] Add 598.5 g of DMAC (N, N-dimethylacetamide) and 200.0 g of phenolic resin to a 1000 ml four-necked flask with temperature-controlled heating, mechanical stirring, reflux and nitrogen protection device P03 (commodity code: TR4020G, m / p=60 / 40, Mw≈13000), heated and stirred at 60°C under nitrogen protection until the solid was dissolved, then added 1.0g of dibutyltin dilaurate, and then slowly added 39.4g of MOI (methacryloyl Oxyethyl isocyanate) was reacted for 4 hours until the peak at 2275 of the active isocyanate group detected by infrared spectroscopy disappeared.

[0083] 26.6g MI (maleimide), 66.5g dried DMAC, 1.3g AIBN (azobisisobutyronitrile) were added to the above reaction solution, and the reaction was completed after 23 hours at 70°C. The reactant was precipitated in deionized water, washed, and vacuum-dried at 40°C to obtain a copolymerized modified phenolic resin P03M. See the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com