A kind of preparation method of dust filter bag

A filter bag and bag body technology, which is applied in the field of dust filter bag preparation, can solve the problems of cloth holes, short service life, easy ash leakage, etc., and achieve the effect of improving work efficiency, long service life and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

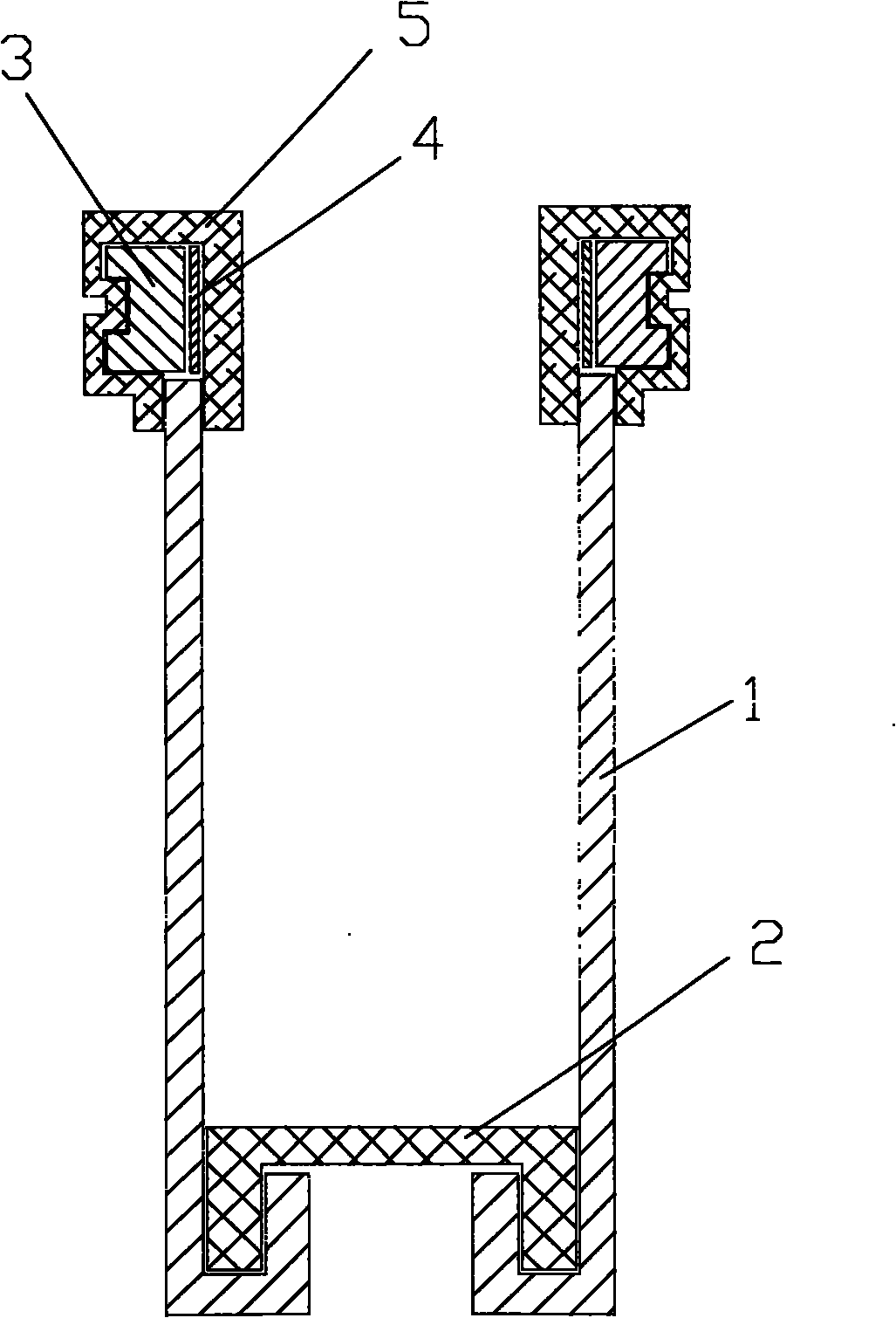

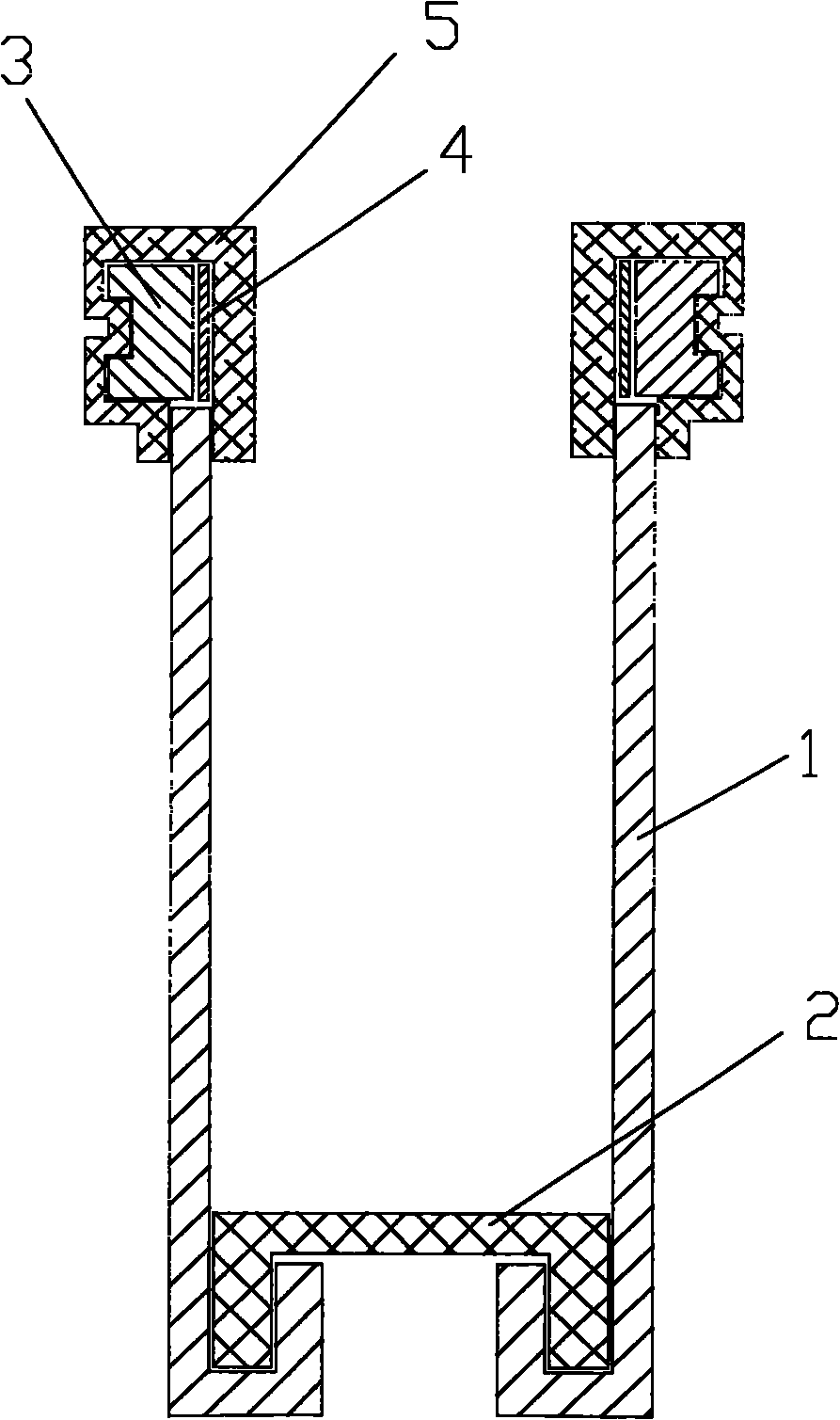

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below.

[0016] A method for preparing a dust-removing filter bag of the present invention comprises bag body preparation, bag mouth preparation and bag bottom preparation. The preparation method of this dust filter bag comprises the following steps:

[0017] 10. Firstly, the bag body is prepared, and the bag body is prepared by ultrasonic welding.

[0018] This step specifically includes the following steps:

[0019] 101. Take a piece of square or rectangular filter cloth; the filter cloth is preferably made of polyester, polypropylene, acrylic, aramid, or polyphenylene sulfide (English full name Polyphenylene Sulfide).

[0020] 102. Curling the filter cloth in step 101, and pasting the curled sides of the filter cloth to form a cylindrical filter cloth.

[0021] 103. Ultrasonic welding is performed on both sides of the bonded filter cloth in step 102 with an ultrasonic instrument to form th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com