Forming process of automobile engine exhaust system heat insulation cover

A technology of automobile engine and exhaust system, which is applied in the field of stamping and forming of auto parts and processing and forming of auto parts, which can solve the problems of high processing cost and low forming quality, so as to improve the forming quality, ensure the processing quality, and not easily cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

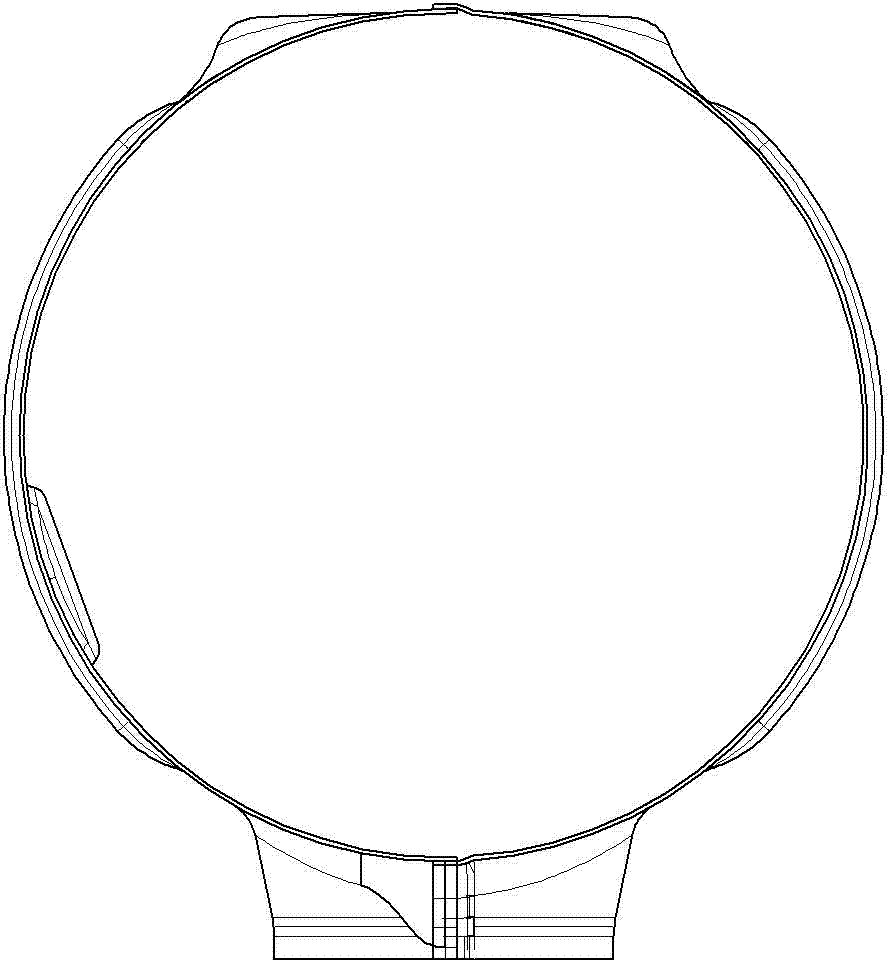

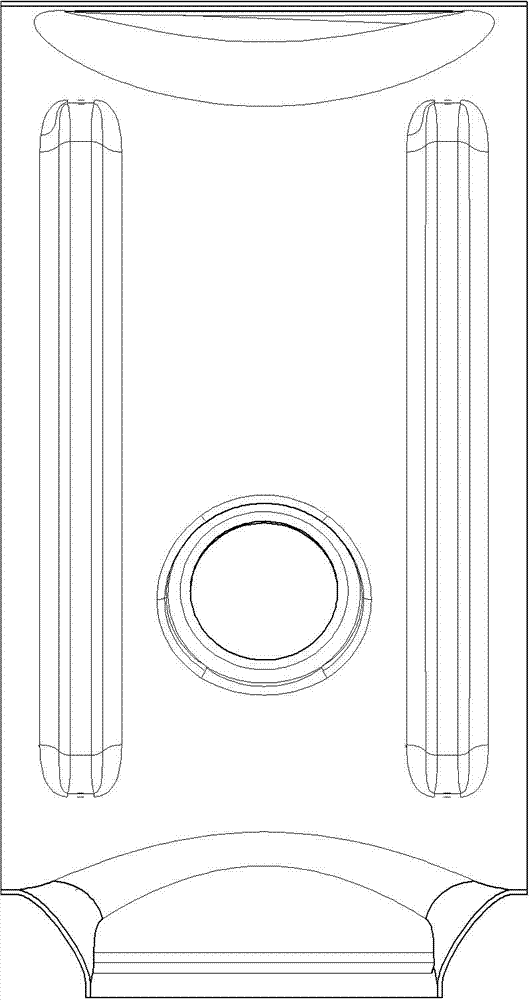

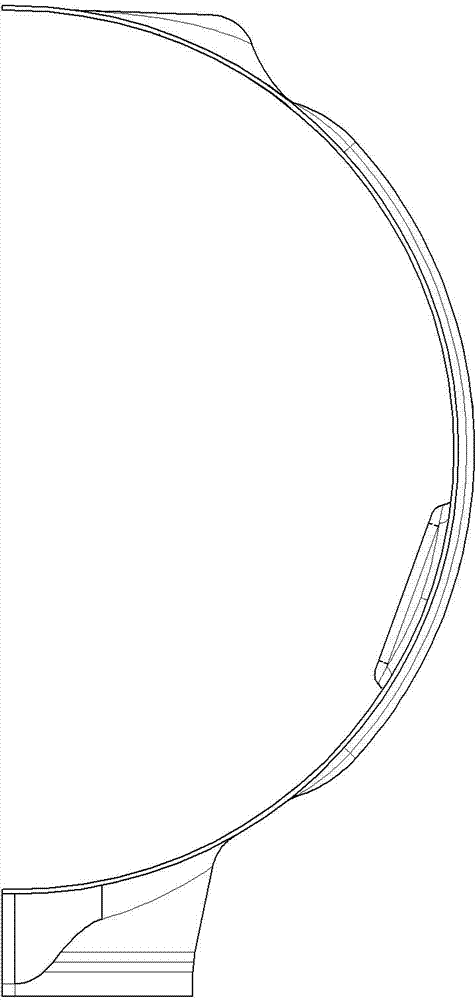

[0039] A forming process for a heat shield of an automobile engine exhaust system, which adopts a cold stamping forming process, which divides the heat shield of an automobile engine exhaust system into left half shells along the longitudinal centerline of its circular air outlet pipe mouth 10 , the right half-shell 20, the left half-shell 10 and the right half-shell 20 are stamped and formed respectively, and then the stamped left half-shell 10 and the right half-shell 20 are welded into a whole.

[0040] Among them, the stamping process of the left half shell 10 and the right half shell 20 first carries out the stamping and forming process on the left half shell 10 and the right half shell 20, and the forming and arrangement directions of the left half shell and the right half shell are opposite, which can make the stamping During processing, the material plate is evenly pressed, so as to ensure that the left half shell and the right half shell are formed in place, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com