Forging method of conical cylinder body of nuclear power equipment

A technology for a conical cylinder and equipment, which is applied in the field of forging, can solve the problems such as the inability to manufacture the conical cylinder of nuclear power equipment and the large weight of forgings, and achieve the effects of reasonable distribution of metal streamlines, dense forging materials and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

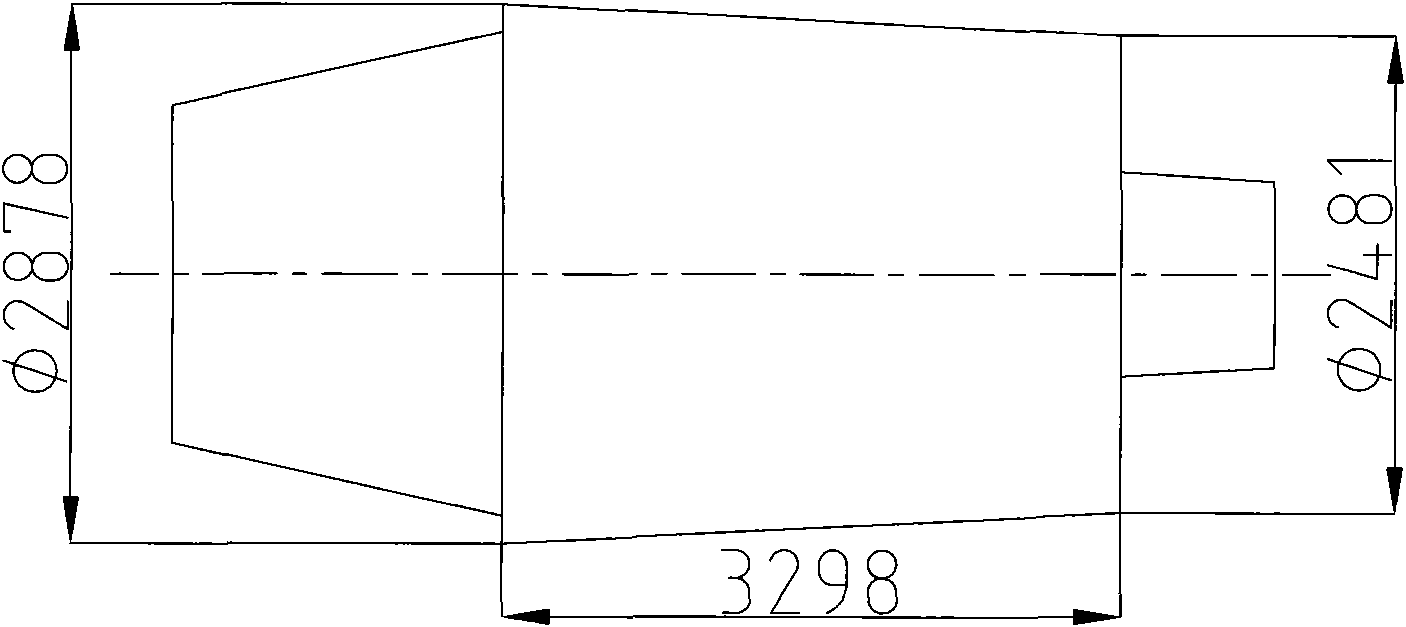

[0023] The forging method of the conical cylinder of nuclear power equipment in the present invention uses a 16,500-ton hydraulic press to forge a double-vacuum steel ingot with a material of 18MND5, a weight of 185 tons, a diameter of 2878mm on the top of the ingot, a diameter of 2481mm on the bottom of the ingot, and a height of 3298mm. To become a tapered cylinder with an outer diameter of 4955mm, an inner diameter of 4240mm, a height of 2720mm, and a taper of 15 degrees on one side, the forging method is divided into the following steps:

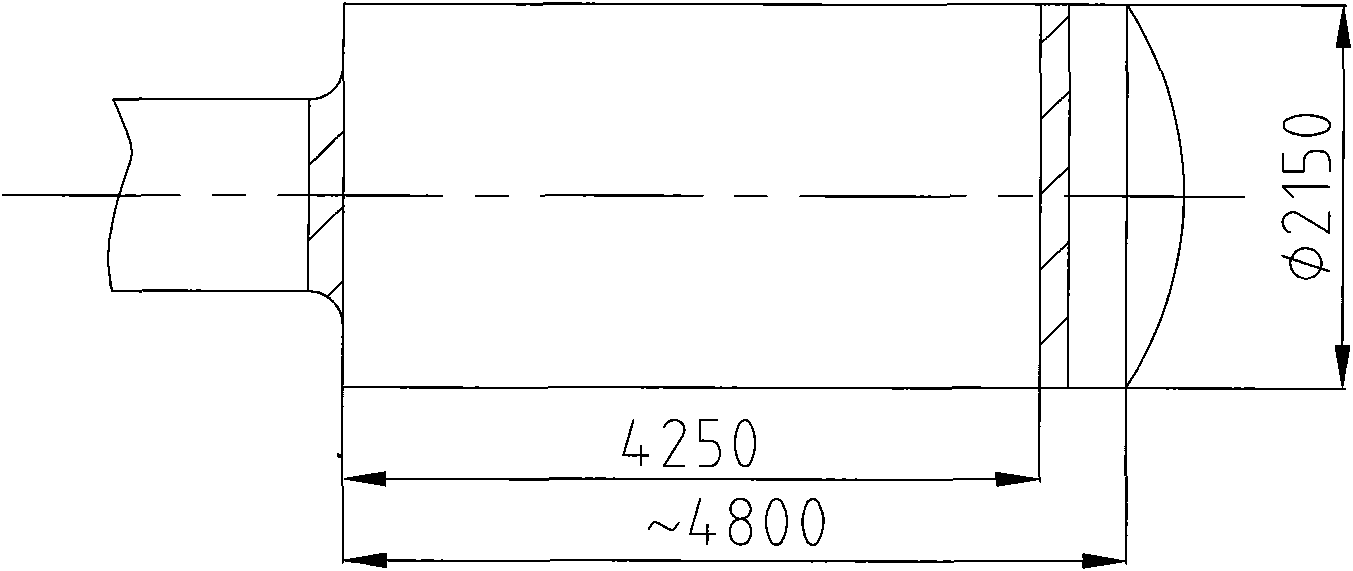

[0024] The first step is to pull out the length; figure 1 The double-vacuum ingot shown is heated to 1220°C and stretched, changing the length of 3298mm to 4800mm, such as figure 2 As shown, make the forging ratio up to 1.45; if the temperature of the forging falls below 850°C during the elongation process, reheat the forging to keep the temperature of the forging within the range of 850-1220°C;

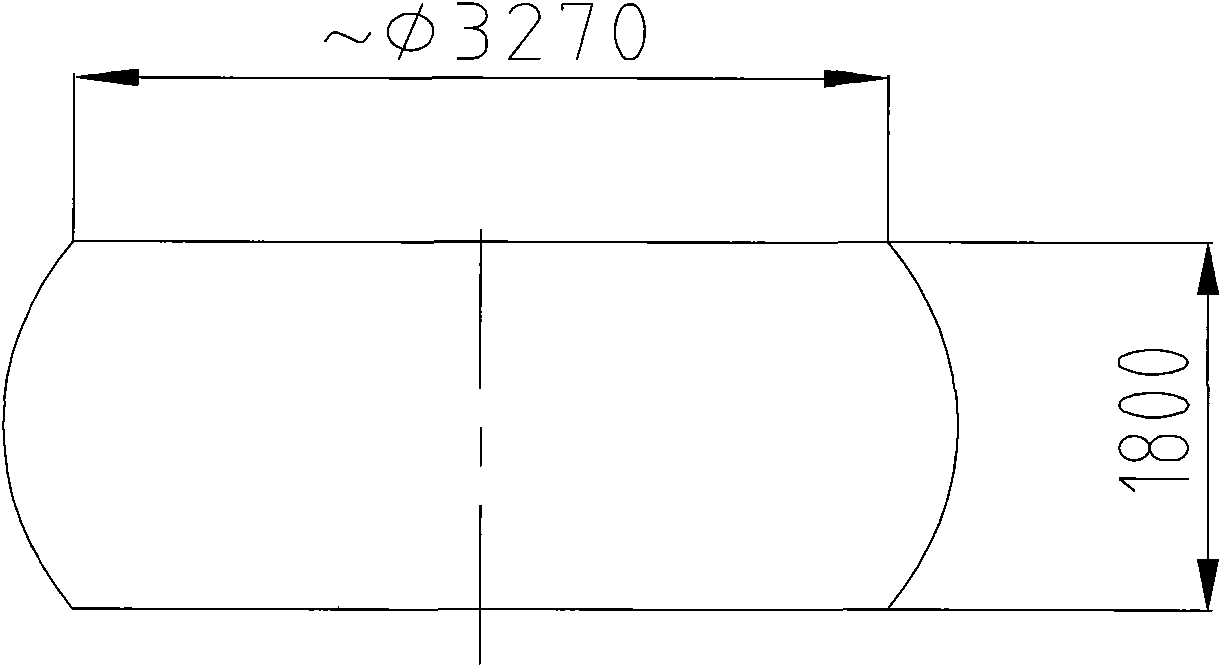

[0025] The second step is to cut the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com