Water-based environment-friendly plastic track adhesive and preparation method thereof

A plastic runway and adhesive technology, applied in the direction of modified epoxy resin adhesives, adhesives, adhesive types, etc., can solve the problems of easy cracking of adhesives, soil environment and groundwater pollution, etc., and achieve excellent UV resistance , improve dispersion, increase the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

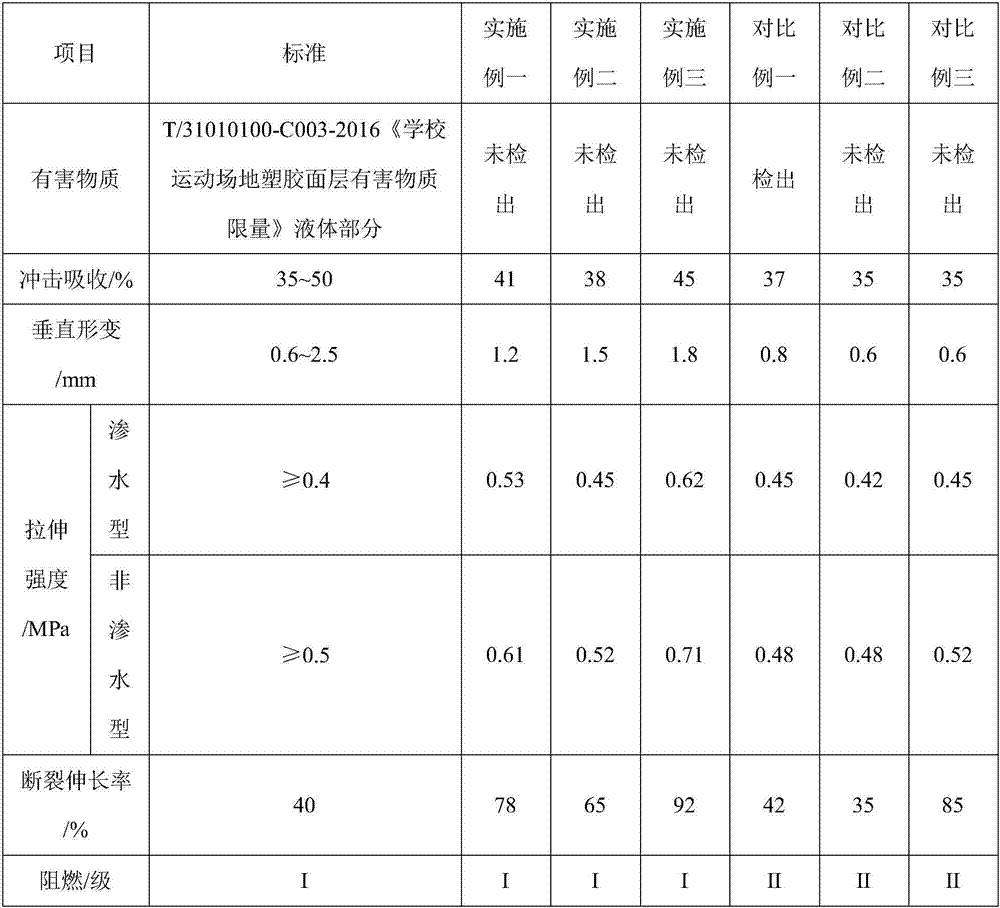

Examples

preparation example Construction

[0044] 1. Preparation of epoxy-acrylic acid hybrid emulsion:

[0045] 1. Prepare raw materials: epoxy resin, acrylic acid monomer and alkyl acrylate monomer, vinyl alkyl phosphate, initiator, neutralizer, deionized water;

[0046] 2. Preparation process:

[0047] (1) Stir 80kg of water, 0.4kg of sodium dodecylsulfonate and 0.1kg of octylphenol polyoxyethylene ether evenly, heat up to 50°C, add 10.2kg of methyl methacrylate, 5.6kg of butyl acrylate and 1.2 kg methacrylic acid, continue to heat up to 75°C; add 0.15kg ammonium persulfate aqueous solution until the emulsion shows obvious blue light; add dropwise the mixed monomer of 10.2kg methyl methacrylate, 5.6kg butyl acrylate and 1.2kg methacrylic acid , dropwise added and incubated for 30 minutes to obtain a seed emulsion;

[0048] (2) While preparing the seed emulsion, dissolve 12kg E-51 epoxy resin with 52kg methyl methacrylate and 26kg butyl acrylate mixed monomer, then add 0.6kg benzoyl peroxide initiator, 0.3kg dodecy...

Embodiment 1

[0057] Add 380kg of water into the stirring container, add 5kg of acrylate copolymer dispersant, 15kg of hydroxyethyl cellulose, 20kg of antifreeze, 5kg of bactericide, and 3kg of defoamer at a stirring speed of 300rpm, fully disperse for 20min, and then stir Add 170kg of epoxy-acrylic hybrid emulsion, 300kg of elastic acrylic emulsion, 7kg of film-forming aids, 5kg of bactericides, 3kg of defoamers, 35kg of functional additives, 50kg of dustproof agents, and 2kg of thickeners at a speed of 500rpm. Further increase the stirring speed to 600rpm, stir for 5 minutes, filter and package as component A after passing the test; mix component A and component B evenly in a ratio of 100:6.2 to obtain a water-based environmentally friendly plastic runway adhesive.

Embodiment 2

[0059] Add 430kg of water into the stirring container, add 7kg of acrylate copolymer dispersant, 16kg of hydroxyethyl cellulose, 20kg of antifreeze, 6kg of bactericide, and 3kg of defoamer at a stirring speed of 300rpm, fully disperse for 20min, and then stir Add 130kg of epoxy-acrylic hybrid emulsion, 280kg of elastic acrylic emulsion, 6kg of film-forming aids, 6kg of bactericides, 4kg of defoamers, 35kg of functional additives, 55kg of dustproof agents, and 2kg of thickeners at a speed of 500rpm. Further increase the stirring speed to 600rpm, stir for 5 minutes, filter and package as component A after passing the test; mix component A and component B evenly in a ratio of 100:5.41 to obtain a water-based environmentally friendly plastic runway adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com