Flexible tile adhesive

A tile adhesive and flexible technology, applied in the field of building materials, can solve problems such as failure to meet engineering needs, hollowing of pasting materials, insufficient adhesion, etc., to avoid hollowing off, not easy to crack, and strong bonding ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

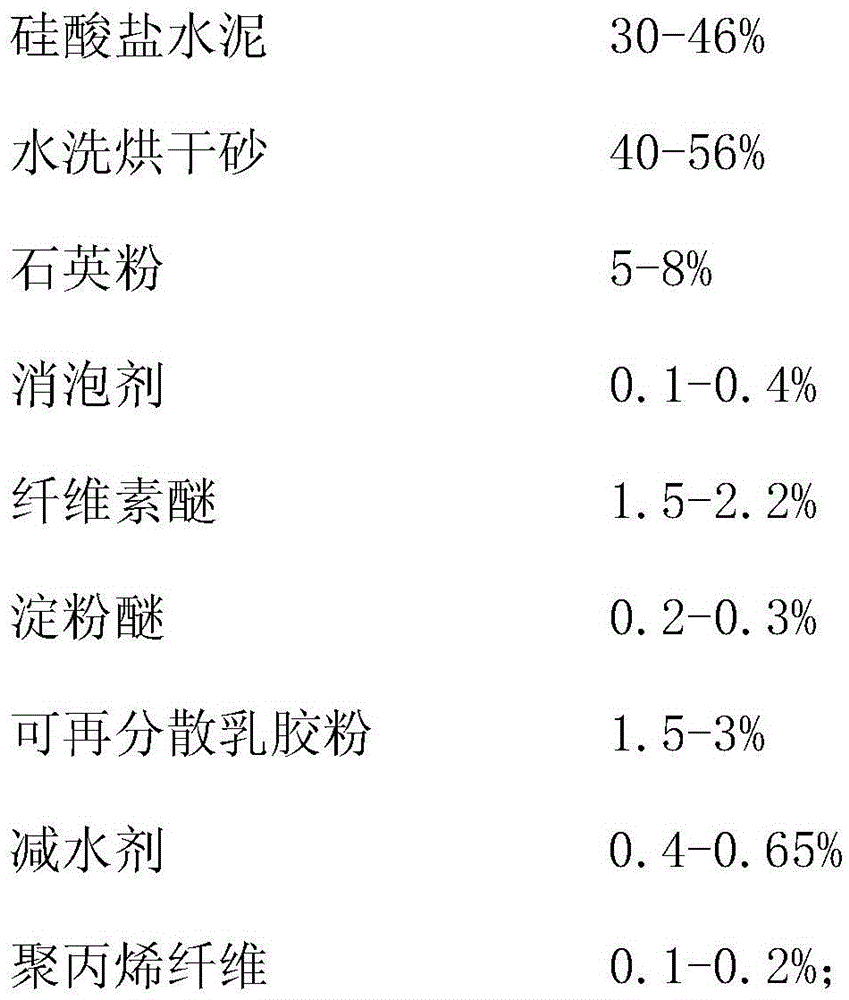

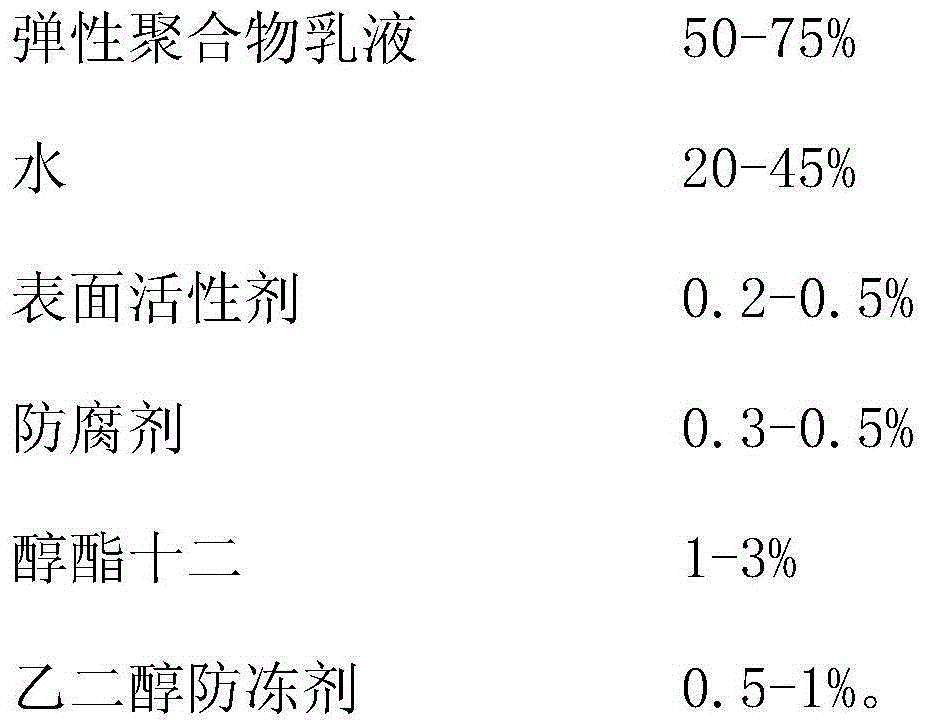

[0027] The invention provides a flexible ceramic tile adhesive, which comprises A component and B component, and the mass ratio of the A component to the B component is 3:1, wherein the A component It is made of the following raw materials in terms of mass percentage: Portland cement 30-46%, washed and dried sand 40-56%, quartz powder 5-8%, defoamer 0.1-0.4%, cellulose ether 1.5-2.2 %, starch ether 0.2-0.3%, redispersible latex powder 1.5-3%, water reducer 0.4-0.65%, polypropylene fiber 0.1-0.2%; the B component is made of the following raw materials by mass percentage: Elastic polymer emulsion 50-75%, water 20-45%, surfactant 0.2-0.5%, preservative 0.3-0.5%, alcohol ester twelve 1-3%, ethylene glycol antifreeze 0.5-1%; The preparation method of the flexible ceramic tile adhesive comprises the following steps: according to the above mass percentage, first weigh each raw material of component A, put them into a mixer in turn, and after fully stirring and mixing uniformly, obtai...

Embodiment 1

[0031] In the flexible tile adhesive, component A is made of the following raw materials by mass percentage:

[0032]

[0033]

[0034] Component B is made of the following raw materials by mass percentage:

[0035]

[0036] The flexible ceramic tile adhesive made with the ratio shown in Example 1 is less prone to cracking, hollowing, and falling off, and has better flow resistance.

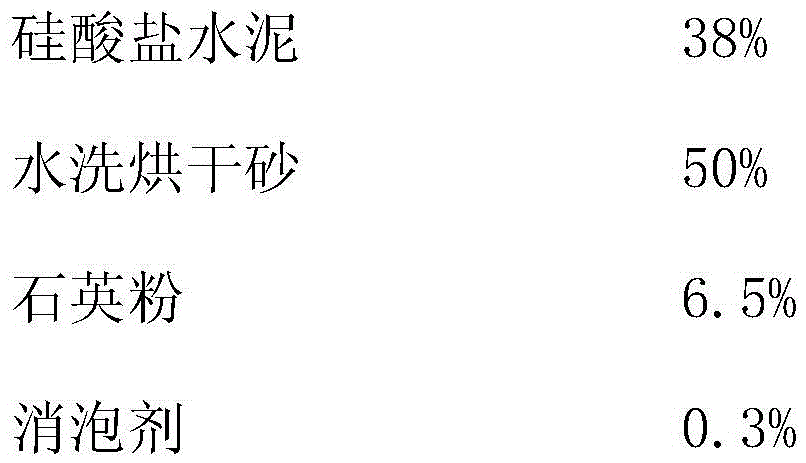

Embodiment 2

[0038] In the flexible tile adhesive, component A is made of the following raw materials by mass percentage:

[0039]

[0040]

[0041] Component B is made of the following raw materials by mass percentage:

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com