Preparation method of ternary precursor with bulk phase doped with rare earth elements and positive electrode material of ternary precursor

A technology of rare earth elements and positive electrode materials, applied in chemical instruments and methods, electrical components, battery electrodes, etc., can solve the problems of poor element modification performance, poor mixing uniformity, and affecting lithium source embedding, etc. Improved discharge and DC internal resistance, less cracking, good electrochemical cycle performance and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

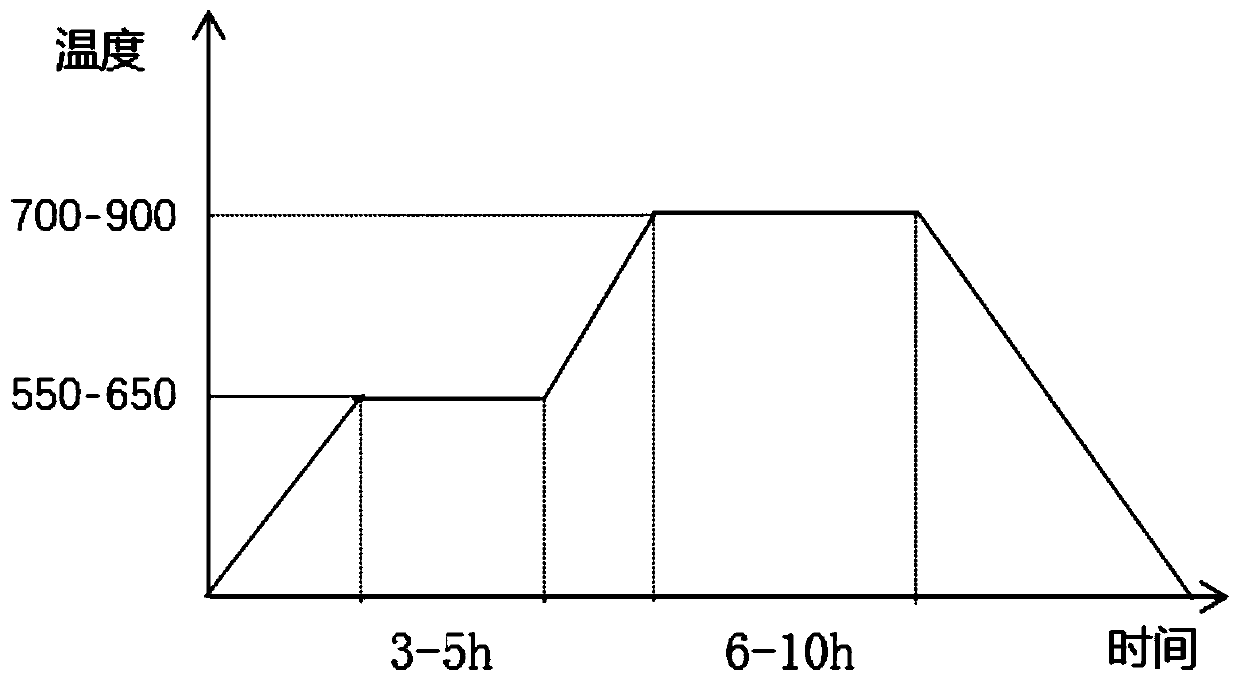

Method used

Image

Examples

Embodiment 1

[0034] Step 1, configure the nickel-cobalt-manganese salt solution: weigh NiSO according to the stoichiometric ratio 4 ·6H 2 O, MnSO 4 ·H 2 O, CoSO 4 ·7H 2 O and Tb(NO 3 ) 3 ·6H 2 O solid powder, dissolve it into 20L of deionized water, weigh mol(Ni):mol(Mn):mol(Co):mol(Tb)=0.83:0.115:0.05:0.005, and call the salt solution A solution;

[0035] Step 2, the complexing agent NaOH is prepared, the preparation concentration is 5mol / L, the preparation total volume is 15L, and this solution is called B solution.

[0036] Step 3, prepare the bottom solution (ammonia water), the concentration is 6mol / L, the preparation volume is 5L, this solution is called C solution.

[0037] Step 4, after the above-mentioned powders are completely dissolved in deionized water to form an unsaturated solution, take 2L of solution C and inject it into the reactor as the bottom liquid, and then connect the containers containing solution A, solution B and solution C to the self-priming pump of t...

Embodiment 2

[0047] Step 1, configure the nickel-cobalt-manganese salt solution: weigh NiSO according to the stoichiometric ratio 4 ·6H 2 O, MnSO 4 ·H 2 O, CoSO 4 ·7H 2 O and Eu(NO 3 ) 3 ·6H 2 O solid powder, dissolve it into 20L of deionized water, weigh mol(Ni):mol(Mn):mol(Co):mol(Eu)=0.59:0.17:0.17:0.07, and call the salt solution A solution;

[0048] Step 2, the complexing agent NaOH is prepared, the preparation concentration is 8mol / L, the preparation total volume is 10L, and this solution is called B solution.

[0049] Step 3, preparing a bottom solution (aqueous ammonia) with a concentration of 10 mol / L and a volume of 4 L. This solution is called C solution.

[0050] Step 4, after the above-mentioned powders are completely dissolved in deionized water to form an unsaturated solution, take 2L of solution C and inject it into the reactor as the bottom liquid, and then connect the containers containing solution A, solution B and solution C to the self-priming pump of the rea...

Embodiment 3

[0057] Step 1, configure the nickel-cobalt-manganese salt solution: weigh NiSO according to the stoichiometric ratio 4 ·6H 2 O, MnSO 4 ·H 2 O, CoSO 4 ·7H 2 O and Eu(NO 3 ) 3 ·6H 2 O solid powder, put it into 20L deionized water, weigh mol(Ni):mol(Mn):mol(Co):mol(La)=0.5:0.2:0.22:0.08, and call the salt solution A solution;

[0058] Step 2, the complexing agent NaOH is prepared, the preparation concentration is 3mol / L, the preparation total volume is 20L, and this solution is called B solution.

[0059] Step 3, prepare the bottom solution (ammonia water), the concentration is 5mol / L, the preparation volume is 10L, this solution is called C solution.

[0060] Step 4, after the above-mentioned powders are completely dissolved in deionized water to form an unsaturated solution, take 5L of solution C and inject it into the reactor as the bottom liquid, and then connect the containers containing solution A, solution B and solution C to the self-priming pump of the reactor,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com