Environment-friendly epoxy seaming paste and preparation method thereof

An environmentally friendly, epoxy technology, applied in the field of joint materials, can solve the problems of short service life of joint paste, affect the decorative effect, complicated construction procedures, etc., and achieve the effect of not easy to crack, low limit of harmful substances, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] An environment-friendly epoxy joint paste, which is prepared by mixing the main paint and curing agent at a mass ratio of 2:0.8-1.2, wherein the main paint and curing agent are prepared by the following components and weight ratios:

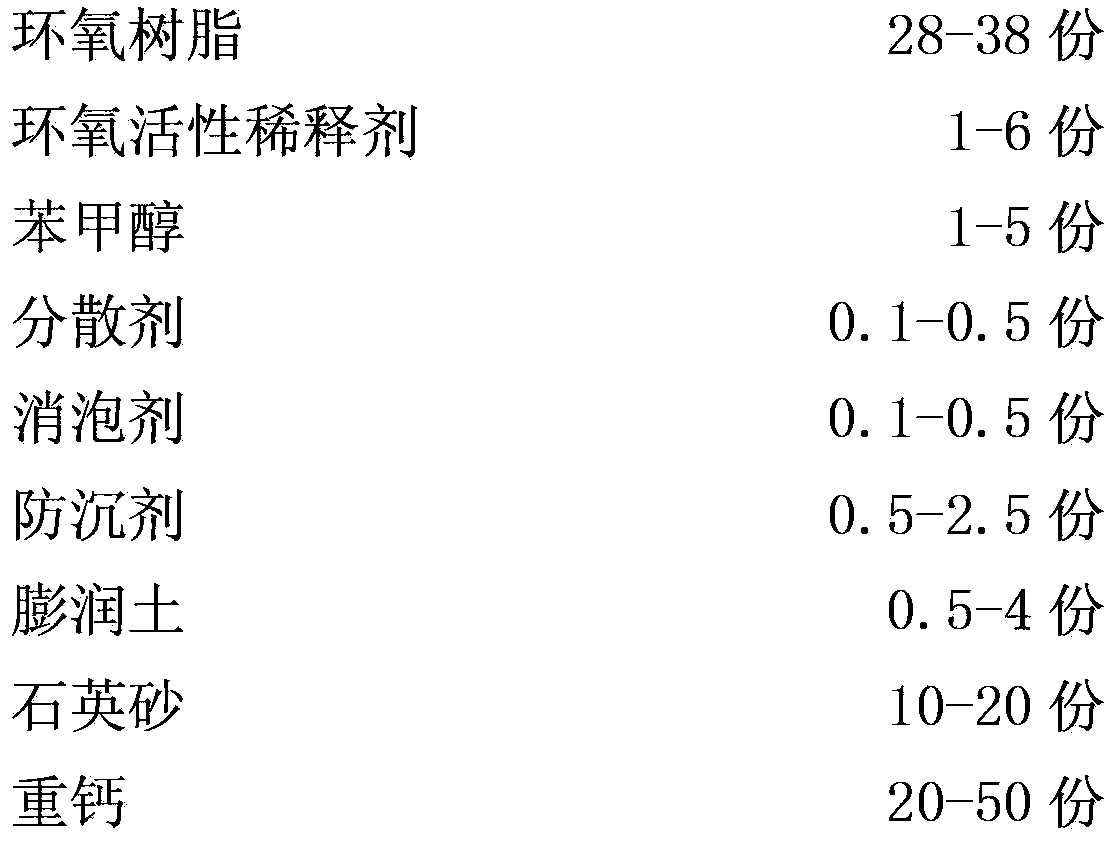

[0028] Wherein the main paint component and parts by weight ratio are as follows:

[0029]

[0030]

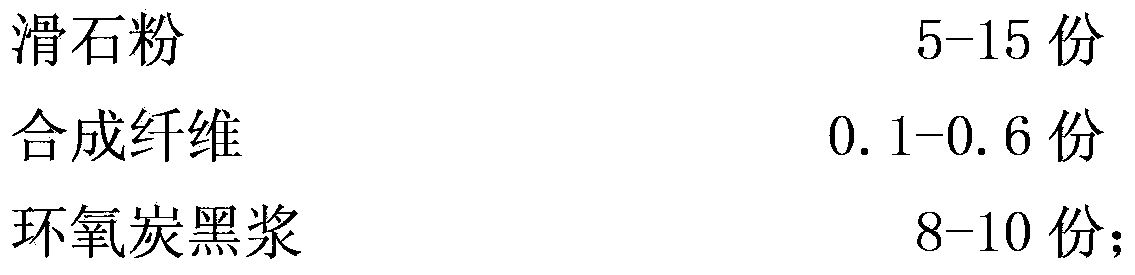

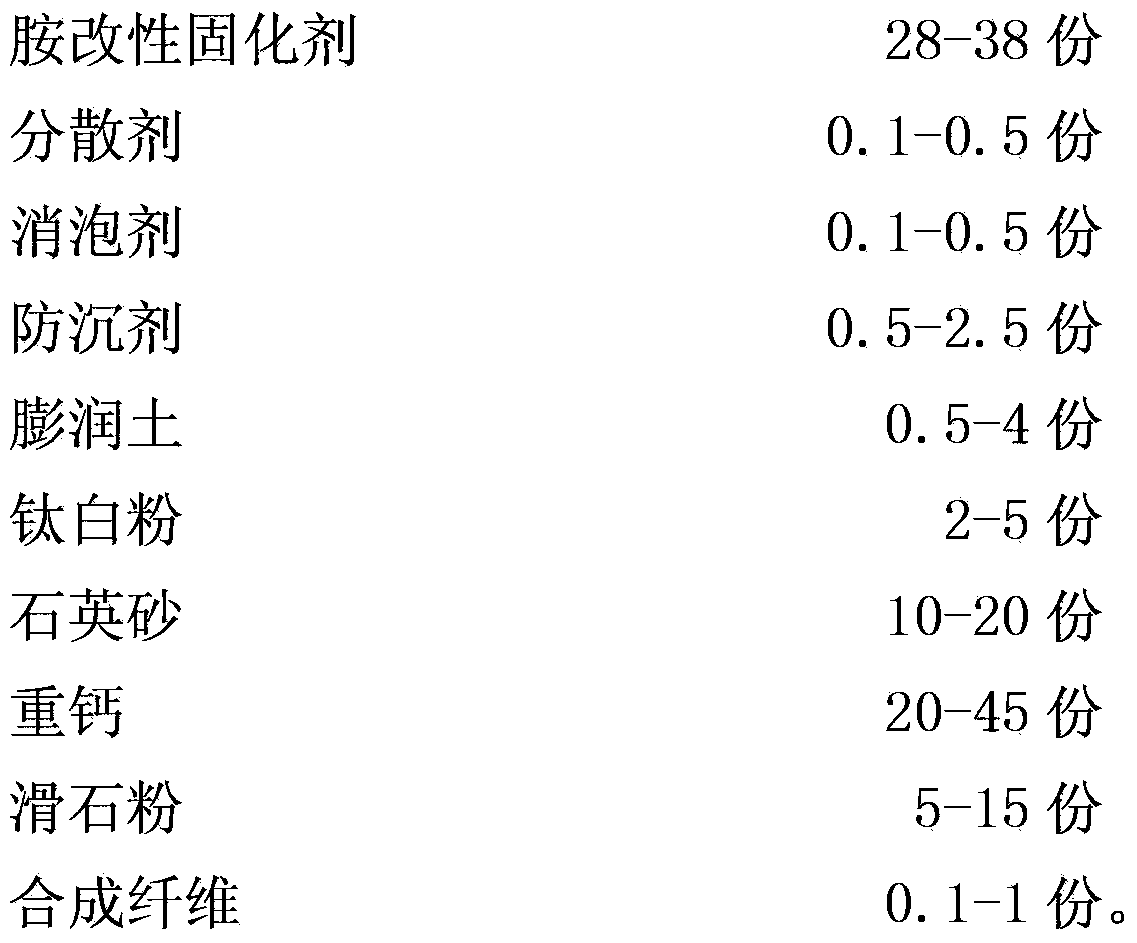

[0031] Wherein curing agent component and parts by weight ratio are as follows:

[0032]

[0033] The preparation method of above-mentioned environment-friendly type epoxy joint paste, comprises the steps:

[0034] (1) The main paint is prepared according to the following preparation method:

[0035] Add epoxy resin, epoxy reactive diluent, benzyl alcohol, dispersant, defoamer, anti-sedimentation agent, bentonite, quartz sand, heavy calcium, talcum powder, synthetic fiber, and epoxy carbon black slurry into the container in sequence , disperse in a mixer at 1000-1200 rpm for 10-15 minutes until evenly mixed;

[0036] (2) The cu...

Embodiment 1

[0041] Embodiment 1: An environment-friendly epoxy joint paste is formed by mixing the main paint and curing agent in a mass ratio of 2:1, wherein the main paint and curing agent are formulated by the following components and parts by weight:

[0042] Wherein the main paint component and parts by weight ratio are as follows:

[0043]

[0044] Wherein curing agent component and parts by weight ratio are as follows:

[0045]

[0046]

[0047] A preparation method of environment-friendly epoxy joint paste comprises the steps:

[0048] (1) The main paint is prepared according to the following preparation method:

[0049] 28 parts of epoxy resin, 4 parts of epoxy reactive diluent, 3 parts of benzyl alcohol, 0.3 parts of dispersant, 0.3 parts of defoamer, 1 part of anti-sedimentation agent, 2.5 parts of bentonite, 13 parts of quartz sand, 30 parts of heavy calcium , 9.7 parts of talcum powder, 0.2 parts of synthetic fiber, and 8 parts of epoxy carbon black slurry are adde...

Embodiment 2

[0057] Embodiment 2: An environment-friendly epoxy joint paste is formed by mixing the main paint and the curing agent in a mass ratio of 2:0.8, wherein the main paint and the curing agent are formulated by the following components and parts by weight:

[0058] Wherein the main paint component and parts by weight ratio are as follows:

[0059]

[0060] Wherein curing agent component and parts by weight ratio are as follows:

[0061]

[0062] A preparation method of environment-friendly epoxy joint paste comprises the steps:

[0063] (1) The main paint is prepared according to the following preparation method:

[0064] 32 parts of epoxy resin, 3 parts of epoxy reactive diluent, 4 parts of benzyl alcohol, 0.3 parts of dispersant, 0.3 parts of defoamer, 1 part of anti-settling agent, 2.5 parts of bentonite, 10.7 parts of quartz sand, 30 parts of heavy calcium , 8 parts of talcum powder, 0.2 parts of synthetic fiber, and 8 parts of epoxy carbon black slurry are added to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com