High-performance alkali-activated slag-based seawater coral aggregate concrete and preparation method thereof

An alkali-excited, high-performance technology, applied in the field of high-performance alkali-excited slag-based seawater coral aggregate concrete and its preparation, can solve the problems of low concrete strength, fast setting time, poor durability, etc. Effects of energy consumption, improved serviceability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in more detail below with reference to schematic diagrams, wherein preferred embodiments of the present invention are shown, and it should be understood that those skilled in the art can modify the present invention described herein while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

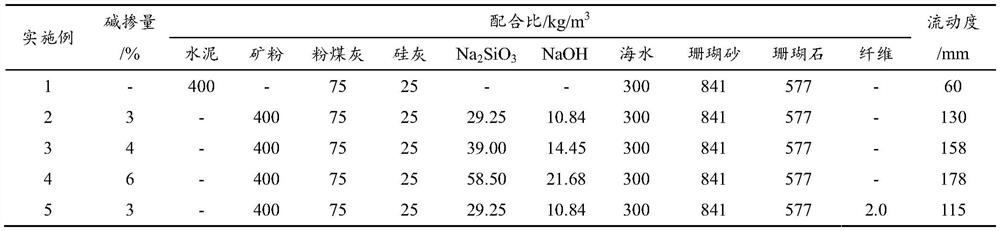

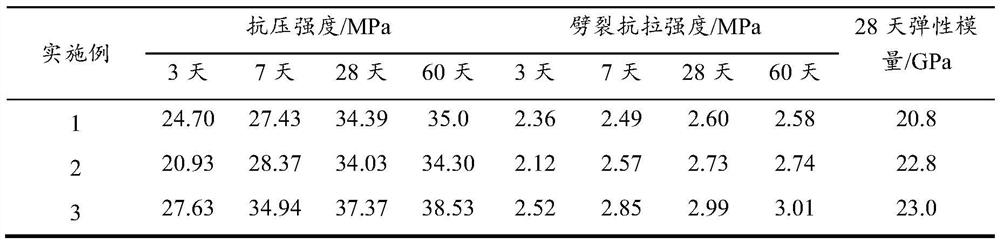

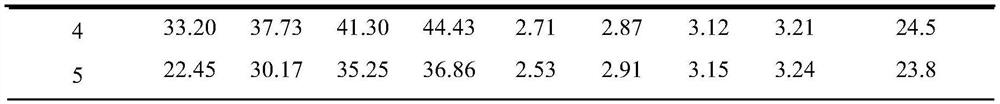

[0030] A high-performance alkali-activated slag-based seawater coral aggregate concrete, which alleviates the disadvantages of fast setting time and large shrinkage faced by alkali-activated all-slag-based cementitious materials by adjusting the ratio of the components of the cementitious material, without weakening Under the premise of strength, a good workability and strength ratio is selected, and then fiber is added for toughening. The ultimate goal is to make this con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com