Ultralow-density cement paste system for well cementing

An ultra-low density, cement slurry technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of cement slurry leakage, affecting the design flowback height of cement slurry and cementing quality, etc., and achieve low water loss. , Rapid development of early strength, good settlement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An ultra-low density cement slurry system for cementing, and its preparation method is as follows:

[0023] S1. Preparation of suspension stabilizer: Weigh 50g of polyvinyl alcohol 1788, 35g of sodium silicate, 13g of sodium alginate and 2g of gypsum, dry mix and stir well, and set aside;

[0024] S2. Preparation of lightening materials: Weigh 5g sodium bentonite, 5g palygorskite and 100g hollow glass beads and mix them evenly;

[0025] S3. Preparation of ultra-low density cement slurry: Weigh 280g G-grade oil well cement, 10g ultrafine cement, 14g microsilica, 110g lightening material, 14g suspension stabilizer, 13.5g coagulant, 3g fluid loss agent and 4g dispersant , Sequentially add to 345mL water and stir evenly.

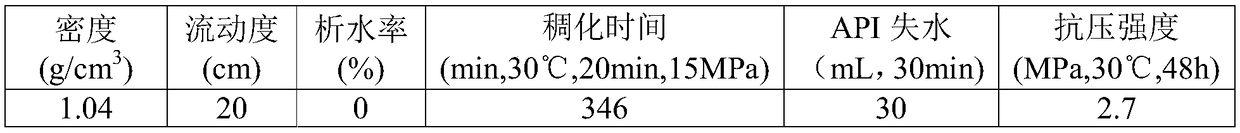

[0026] Taking the ultra-low-density cement slurry system prepared in Example 1 as the test object, the solid components and water of the cement slurry system were first weighed and mixed evenly, and then the slurry was prepared according to the standard GB / T 1913...

Embodiment 2

[0030] An ultra-low density cement slurry system for cementing, and its preparation method is as follows:

[0031] S1. Preparation of suspension stabilizer: weigh 60g polyvinyl alcohol 1788, 30g sodium silicate, 7g sodium alginate and 3g gypsum, dry mix and stir well, and set aside;

[0032] S2. Preparation of lightening materials: weigh 20g expanded perlite and 90g hollow glass beads and mix them evenly;

[0033] S3. Preparation of ultra-low-density cement slurry: Weigh 280g G grade oil well cement, 20g microsilica, 110g lightening material, 8.4g suspension stabilizer, 14g coagulant, 3g fluid loss agent and 3g dispersant, and add them to 316mL in sequence Water and stir well.

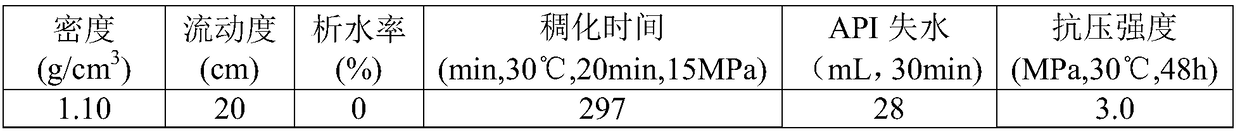

[0034] Taking the ultra-low-density cement slurry system prepared in Example 2 as the test object, first weigh the solid components and water of the cement slurry system and mix them evenly, and then prepare according to the standard GB / T 19139 "Oil Well Cement Test Method" For the slurry, refer to the oil we...

Embodiment 3

[0038] An ultra-low density cement slurry system for cementing, and its preparation method is as follows:

[0039] S1. Preparation of suspension stabilizer: weigh 60g polyvinyl alcohol 1788, 30g sodium silicate, 9g sodium alginate and 1g gypsum, dry mix and stir evenly, set aside;

[0040] S2. Preparation of lightening materials: Weigh 5g sodium bentonite and 70g hollow ceramic beads, and mix them evenly;

[0041] S3. Preparation of ultra-low-density cement slurry: Weigh 280g G grade oil well cement, 20g microsilica, 75g lightening material, 8.4g suspension stabilizer, 14g coagulant, 3g fluid loss agent and 3g dispersant, and add them to 280mL in sequence Water and stir well.

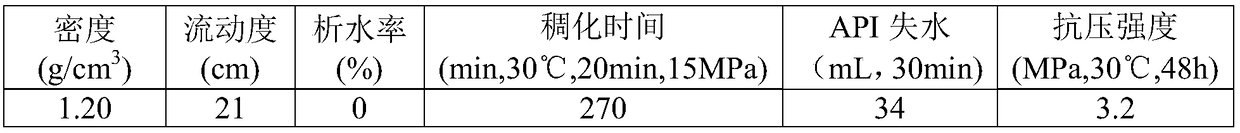

[0042] Taking the ultra-low-density cement slurry system prepared in Example 3 as the test object, first weigh the solid components and water of the cement slurry system and mix them evenly, and then prepare according to the standard GB / T 19139 "Oil Well Cement Test Method" For the slurry, refer to the oil wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com