Modified limestone powder high-performance mineral admixture and preparation method thereof

A limestone powder, high-performance technology, applied in the field of modified limestone powder high-performance mineral admixture and its preparation, can solve the unfavorable quality and cost control of ready-mixed concrete, the improvement of cement and concrete performance is not obvious, and the loss of concrete workability is accelerated and other problems, to achieve the effect of good workability and strength, prolong the setting time, and accelerate the hydration of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-performance composite mineral admixture of modified limestone powder, which comprises the following components in parts by mass: 40 parts of limestone powder, 55 parts of phosphorus slag, 5 parts of active calcium-aluminum modifier, and 0.2 parts of reinforcing activator part; the calcium-aluminum modifier is composed of carbide slag 40wt% and metakaolin 60wt% in mass percentage; the enhanced activator is composed of methylolacrylamide-acrylamide copolymer 10wt% in mass percentage, polymerization Alcohol amine 30wt% and triisopropanolamine 60wt%.

[0030] Dry the above-mentioned limestone powder, phosphorous slag and active calcium-aluminum modifier at 105°C and mix them evenly to obtain a mixed powder, mix it with a reinforcing activator, put it in a ball mill, and grind it for 20-50 minutes to obtain a modified limestone powder The specific surface area of the finished high-performance composite mineral admixture was measured at different grinding times, as s...

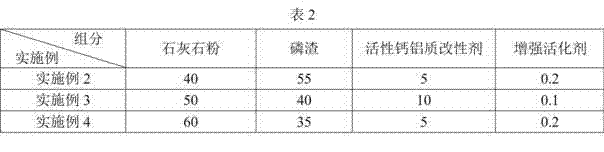

Embodiment 2-4

[0037]The mass parts of each component of the modified limestone powder high-performance composite mineral admixture described in embodiment 2-4 are shown in Table 2, wherein, the limestone powder and phosphorus slag adopted in each embodiment are all the same, and the active calcium aluminum The compositions of the quality modifier and the reinforcement activator are also the same. The calcium-aluminum modifier is composed of 50wt% calcium carbide slag and 50wt% metakaolin in terms of mass percentage; the reinforcing activator is composed of 10wt% of methylolacrylamide-acrylamide copolymer, polymerized alcohol 35wt% and triisopropanolamine 55wt%.

[0038] Dry the above-mentioned limestone powder, phosphorous slag and active calcium-aluminum modifier at 105°C and mix them evenly. The mixed powder obtained is mixed with the reinforcing activator and placed in a ball mill. Grinding for 30 minutes, the high-performance modified limestone powder is obtained. Composite mineral adm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com