Special concrete for structure reinforcement and preparation method thereof

A concrete and special technology, applied in the field of concrete, can solve the problems of poor pouring and tamping effect, slow strength development, long transportation distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

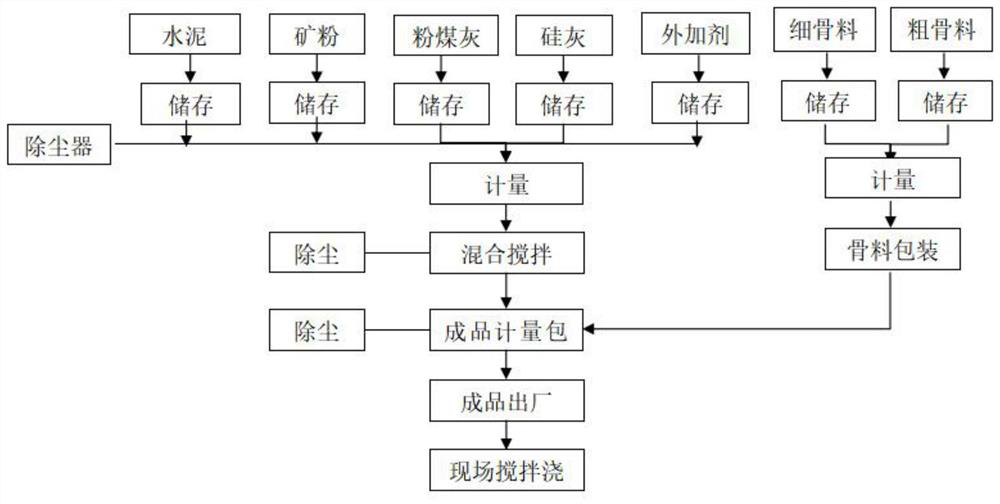

Method used

Image

Examples

Embodiment 1

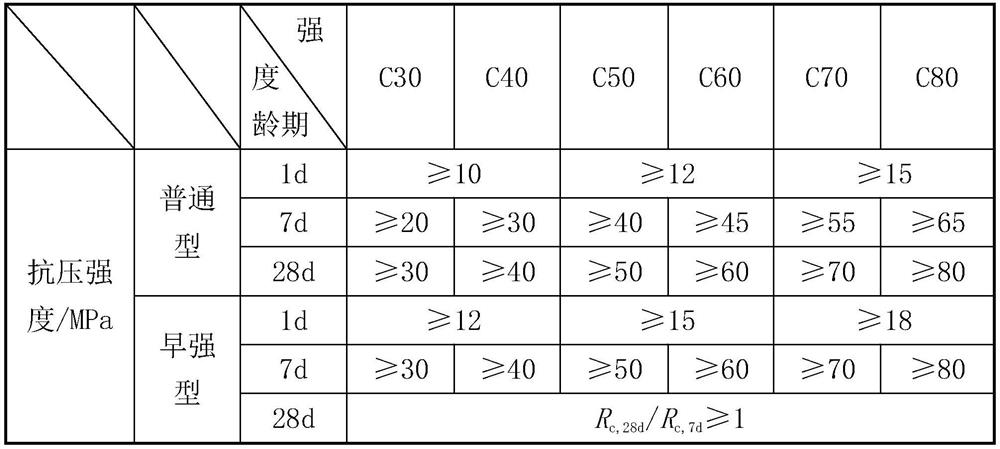

[0034] Example 1, a special concrete for structural reinforcement, according to cement 18, slag powder 3, fly ash 2.06, silica fume 1, water reducing agent 0.4, shrinkage compensating admixture 1.5, anti-crack fiber 0.04, bonding The weight ratio of agent 0 was weighed separately, mixed and prepared into dry powder, and then weighed according to coarse aggregate 36 and fine aggregate 38, mixed and prepared into aggregate, and then the dry powder and aggregate were added to the forced stirring device Pre-mixing in medium, then add water into the mixing device at one time and continue stirring to obtain the product ordinary special reinforced concrete C40;

Embodiment 2

[0035] Example 2, a special concrete for structural reinforcement, according to cement 24, slag powder 3, fly ash 2.76, silica fume 0, water reducer 0.7, shrinkage compensating admixture 1.5, anti-crack fiber 0.04, bonding The weight ratio of agent 0 was weighed separately, mixed and prepared into dry powder, and then weighed according to coarse aggregate 34 and fine aggregate 34, mixed and prepared into aggregate, and then the dry powder and aggregate were added to the forced stirring device Pre-mixing in medium, then add water into the mixing device at one time and continue stirring to obtain the product ordinary special reinforced concrete C60;

Embodiment 3

[0036] Example 3, a special concrete for structural reinforcement, according to cement 25, slag powder 2, fly ash 2.56, silica fume 0, water reducer 0.7, shrinkage compensating admixture 1.5, anti-crack fiber 0.04, bonding The weight ratio of agent 0.2 was weighed separately, mixed and prepared into dry powder, and then weighed separately according to coarse aggregate 34 and fine aggregate 34, mixed and prepared into aggregate, and then the dry powder and aggregate were added to the forced stirring device Pre-mixing in medium, then add water into the mixing device at one time and continue stirring to obtain the product early-strength special reinforced concrete C60.

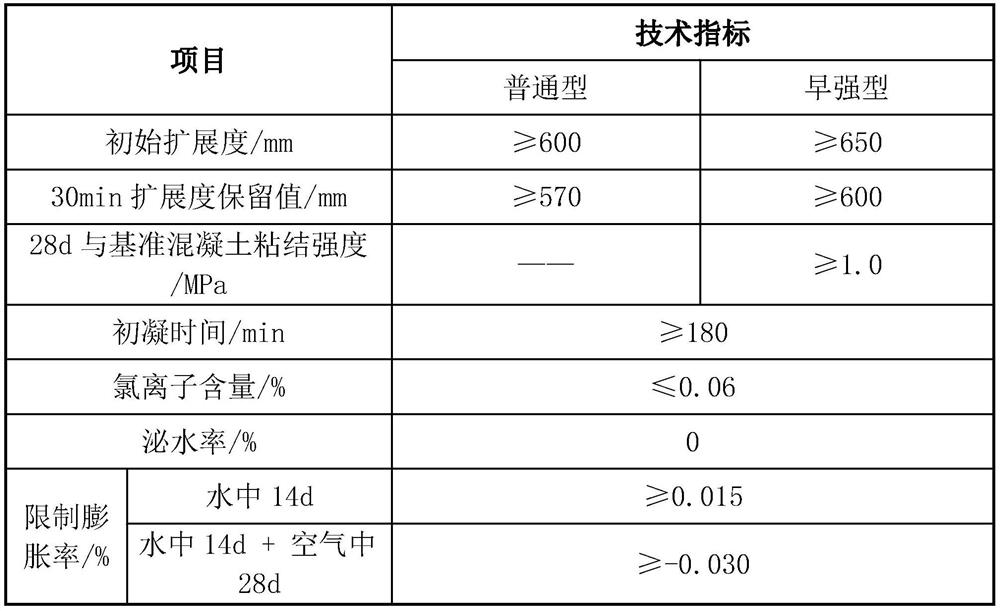

[0037] The stress-strain model, strength standard value, strength design value, fatigue strength correction coefficient and elastic modulus of ordinary and early-strength special reinforced concrete are based on the strength grades in Table 3.1.2-2 and can be used in accordance with the current national standard "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com