Aerated concrete manufactured by stone material waste and manufacturing method thereof

A technology for aerated concrete and stone waste, applied in the field of building materials, can solve the problems of substandard strength, weak structure, incomplete gas generation, etc., and achieve the effects of improving surface quality and strength, saving raw material costs, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

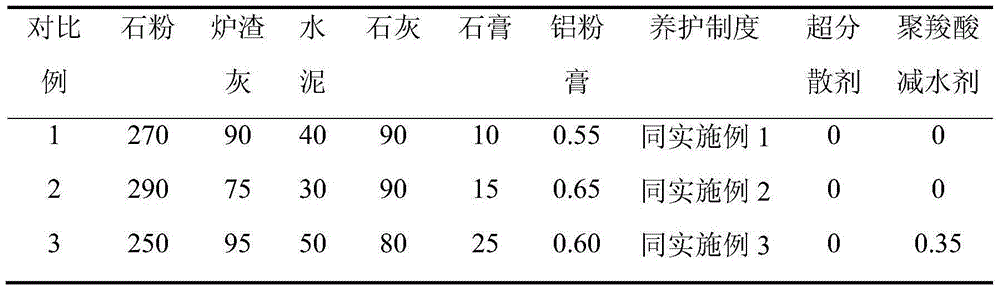

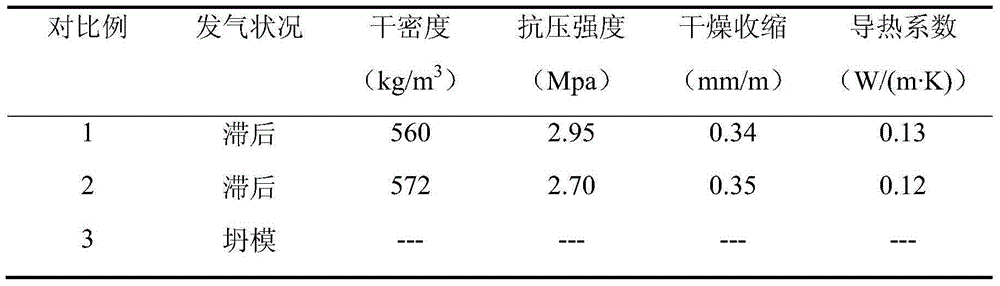

Embodiment 1

[0031] A kind of waste stone material aerated concrete, its preparation method comprises the following steps:

[0032] 1) Weighing of raw materials: Weigh each raw material according to the following weight percentage: pretreated stone powder 270kg / m 3 , slag ash 90kg / m 3 , cement 40kg / m 3 , quicklime 90kg / m 3 , Desulfurization gypsum 10kg / m 3 , Aluminum powder paste 0.65kg / m 3 , hyperdispersant 0.50kg / m 3 ;

[0033] 2) Preparation and maintenance of aerated concrete: mix the above pretreated stone powder with slag ash, cement, quicklime, and desulfurized gypsum according to the ratio, grind and mix in a mixing mill for 3 minutes, and then weigh the water according to the water-to-material ratio of 0.58 for mixing 1min, control the temperature of the slurry at 43°C, and the degree of expansion of the slurry at 290mm to obtain a mixed slurry; add the weighed hyperdispersant to the resulting mixed slurry and stir for 1min, control the fluidity of the mixed slurry to 380mm,...

Embodiment 2

[0036] A kind of waste stone material aerated concrete, its preparation method comprises the following steps:

[0037] 1) Weighing of raw materials: Weigh each raw material according to the following weight percentage: pretreated stone powder 290kg / m 3 , slag ash 65kg / m 3 , Cement 30kg / m 3 , quicklime 100kg / m 3 , Desulfurization gypsum 15kg / m 3 , Aluminum powder paste 0.55kg / m 3 , hyperdispersant 0.50kg / m 3 ;

[0038] 2) Preparation and maintenance of air-entrained concrete: mix the above-mentioned pretreated stone powder with slag ash, cement, quicklime, and desulfurized gypsum according to the ratio, grind and mix in a mixing mill for 3 minutes, and then weigh the water according to the water-to-material ratio of 0.56 for mixing 1.5min, control the temperature of the slurry at 43°C, and the degree of expansion of the slurry at 300mm to obtain a mixed slurry; add the weighed hyperdispersant to the obtained mixed slurry and stir for 1min, and control the fluidity of the ...

Embodiment 3

[0041] A kind of waste stone material aerated concrete, its preparation method comprises the following steps:

[0042] 1) Weighing of raw materials: Weigh each raw material according to the following weight percentage: pretreated stone powder 250kg / m 3 , slag ash 95kg / m 3 , cement 50kg / m 3 , quicklime 80kg / m 3 , Desulfurization gypsum 25kg / m 3 , Aluminum powder paste 0.60kg / m 3 , hyperdispersant 0.35kg / m 3 ;

[0043] 2) Preparation and maintenance of air-entrained concrete: accurately weigh and mix the above pretreated stone powder with slag ash, cement, quicklime, and desulfurized gypsum according to the proportion, grind and mix them in a mixing mill for 2.5 minutes, and then weigh them according to the water-to-material ratio of 0.60 Mix the amount of water for 2 minutes, control the temperature of the slurry at 45 ° C, and the degree of expansion of the slurry at 310 mm to obtain a mixed slurry; add the weighed hyperdispersant to the obtained mixed slurry and stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com