Blank body of fine porcelain ceramic, preparation method and application thereof

A technology of ceramic body and fine ceramics, which is applied in the field of inorganic non-metallic material production, can solve the problem of high production cost of bathroom products that are not suitable for large plane and large size, and fine ceramics, and achieves small firing shrinkage and firing Deformation rate, product straight and regular, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

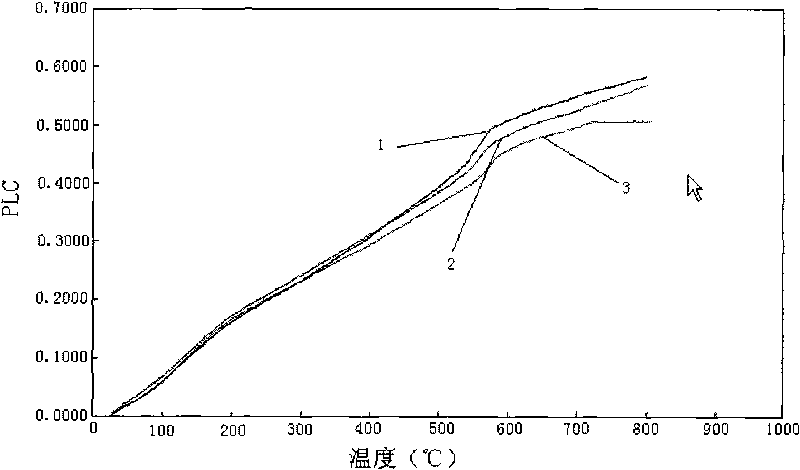

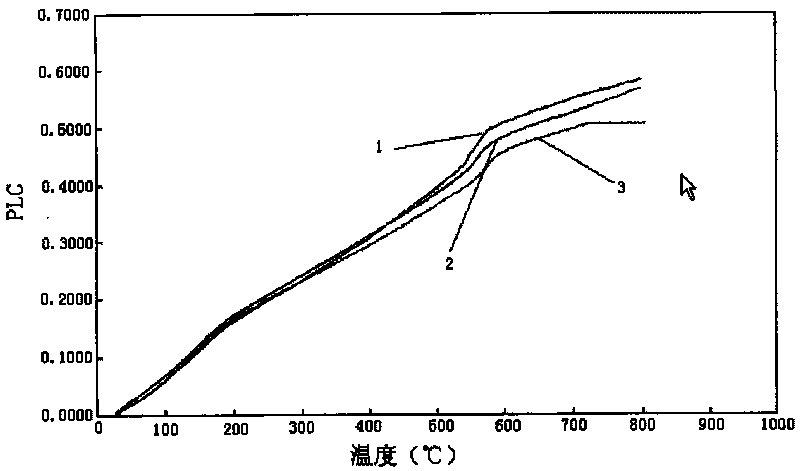

Image

Examples

Embodiment 1~3

[0069] Embodiment 1~3. Preparation fine pottery sanitary ceramic body

[0070] raw material:

[0071] Calcined burnt gem: Al 2 o 3 The weight percentage is 43-48%, the linear shrinkage rate is less than 2.4%, and the 20-1000 degree linear thermal expansion coefficient is 4.4×10 -6 .

[0072] Ceramic waste powder: Obtained after crushing sanitary ceramic waste, and controlling the remaining amount after crushing through a 100-mesh sieve to <3%.

[0073] Quartz sand: SiO in the main mineral quartzite 2 The weight percentage is 97-98%, and the LOI (loss on ignition) is less than 1%.

[0074] Ball clay "The main mineral is kaolinite, containing a small amount of illite, and the impurity minerals are: quartz, lignite, and iron-titanium compounds. This clay is soft clay, with high plasticity, good dispersion, moderate fire resistance, and bonding strength: > 40Mpa. Contains the following chemical weight percentage composition: SiO 2 50-55%, Al 2 o 3 : 23-28%.

[0075] Low-...

Embodiment 4

[0092] Embodiment 4. Preparation fine pottery sanitary ceramics

[0093] raw material:

[0094] Calcined burnt gem: Al 2 o 3 The weight percentage is 43-48%, the linear shrinkage rate is less than 2.4%, and the 20-1000 degree linear thermal expansion coefficient is 4.4×10 -6 .

[0095] Ceramic waste powder: Obtained after crushing sanitary ceramic waste, and controlling the remaining amount after crushing through a 100-mesh sieve to <3%.

[0096] Quartz sand: SiO in the main mineral quartzite 2 The weight percentage is 97-98%, and the LOI (loss on ignition) is less than 1%.

[0097] Ball clay "The main mineral is kaolinite, containing a small amount of illite, and the impurity minerals are: quartz, lignite, and iron-titanium compounds. This clay is soft clay, with high plasticity, good dispersion, moderate fire resistance, and bonding strength: > 40Mpa. Contains the following chemical weight percentage composition: SiO 2 50-55%, Al 2 o 3 : 23-28%.

[0098] Feldspar, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com