Light aggregate cell concrete self-insulating building block and preparation method thereof

A self-insulating block and concrete technology, which is applied in ceramic products, other household appliances, sustainable waste treatment, etc., can solve the problems of easy cracking on the surface of hardened microporous concrete, high water storage rate and high water absorption rate of the insulation layer, etc. , to achieve good self-curing effect, reduce shrinkage, and reduce drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A light-grain microporous concrete self-insulating block, which is prepared from the following raw materials according to mass percentage: 30% cement, 20% industrial waste admixture, 20% light industrial waste granules, 25% water, and 1.0% composite admixture , Foaming agent 0.3%.

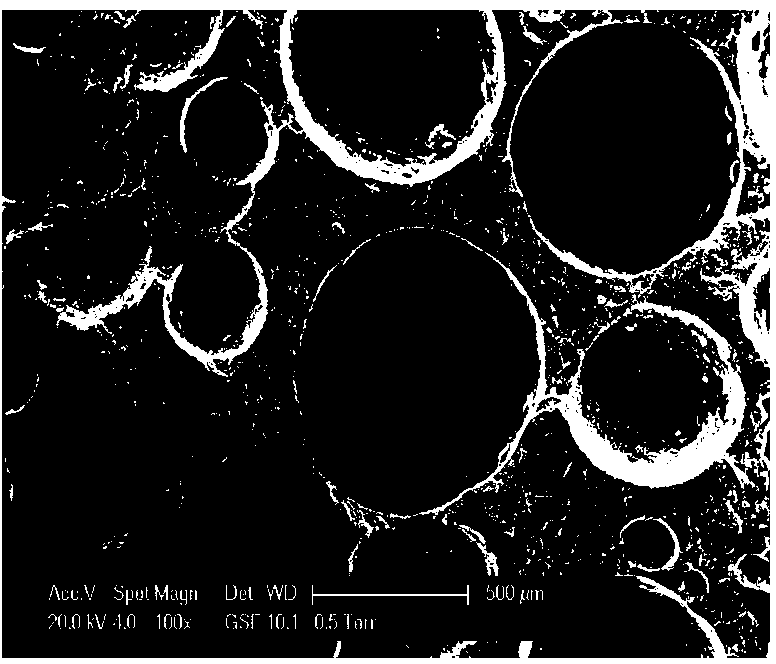

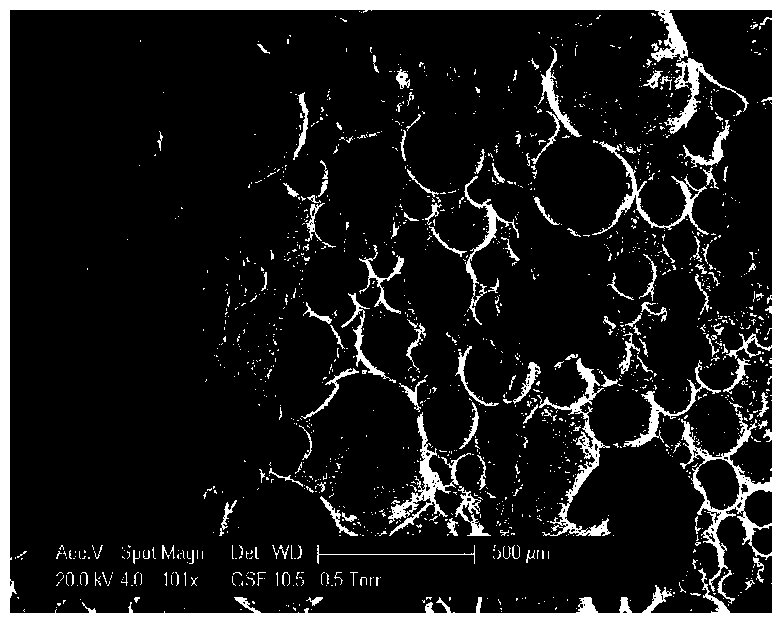

[0034] Among them, the cement is P·Ⅱ52.5 grade Portland cement, and its performance meets the requirements of GB175-2007 "General Portland Cement". The industrial waste admixture is fly ash, the sieve fineness of fly ash 45μm is ≤45%, the activity index is ≥70%, and the performance meets the requirements of GB / T1596-2005 "Fly Ash Used in Cement and Concrete". The light particles of industrial waste are autoclaved aerated concrete fine particles, through mechanical crushing and screening, the particle size is 0.1~10mm, and the bulk density is ≤800kg / m 3 , when used, make it into a saturated face-dry state. The composite admixture includes 20% by mass of water reducing agent, 50% of foam sta...

Embodiment 2

[0041] The raw materials are prepared according to the following mass percentages: 25% cement, 20% industrial waste admixture, 25% light industrial waste granules, 27% water, 1.5% composite admixture, and 0.25% foaming agent.

[0042] Wherein, cement, industrial waste slag light grain are the same as embodiment 1. The industrial waste slag admixture is steel slag powder, and its specific surface area is ≥ 400m 2 / kg, activity index ≥ 75%, and its performance meets the requirements of GB / T20491-2006 "Steel Slag Powder Used in Cement and Concrete". The composite admixture includes 25% water reducing agent, 40% foam stabilizer and 35% water repellent by mass percentage. The foaming agent is a vegetable protein foaming agent, and it is diluted with water at a mass ratio of 1:60 when making foam.

[0043] The preparation steps are the same as in Example 1.

Embodiment 3

[0045] The raw materials are prepared according to the following mass percentages: cement 25%, industrial waste slag admixture 15%, industrial waste light granules 30%, water 29%, composite admixture 2.5%, foaming agent 0.2% + air-entraining agent 0.05%.

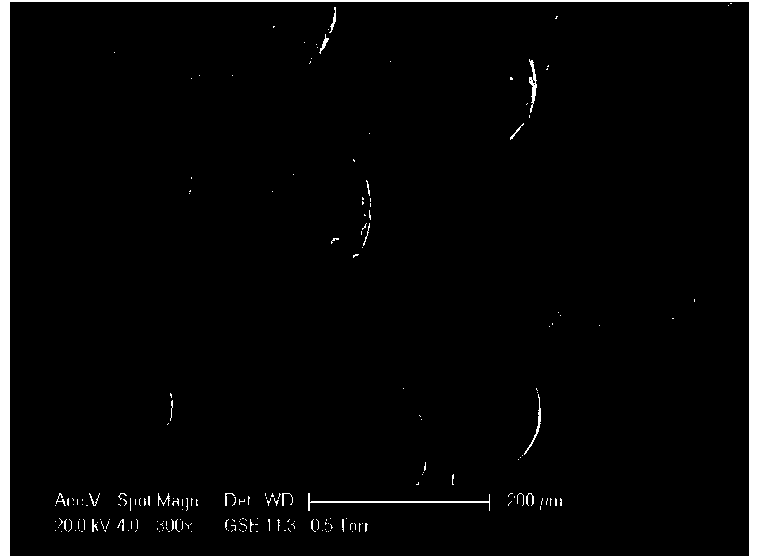

[0046] Wherein, cement, industrial waste slag admixture, and industrial waste slag light grains are the same as in Example 1. The composite admixture includes 30% water reducing agent, 45% foam stabilizer and 25% water repellent by mass percentage. The foaming agent is a vegetable protein foaming agent, and it is diluted with water at a mass ratio of 1:80 when making foam. The air-entraining agent is sodium lauryl sulfate (K12), which is a white to light yellow powder with good emulsifying, foaming, penetrating, decontaminating and dispersing properties.

[0047] The preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com