Gear tooth transfer self-curing type gear

A self-maintaining, tooth-to-tooth technology, which is applied in the direction of gear lubrication/cooling, belt/chain/gear, components with teeth, etc., can solve problems such as difficult control, affecting the service life of gears, and easy wear of gear teeth , to achieve the effect of avoiding oxidation and agglomeration, promoting recovery of deformation, and good maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

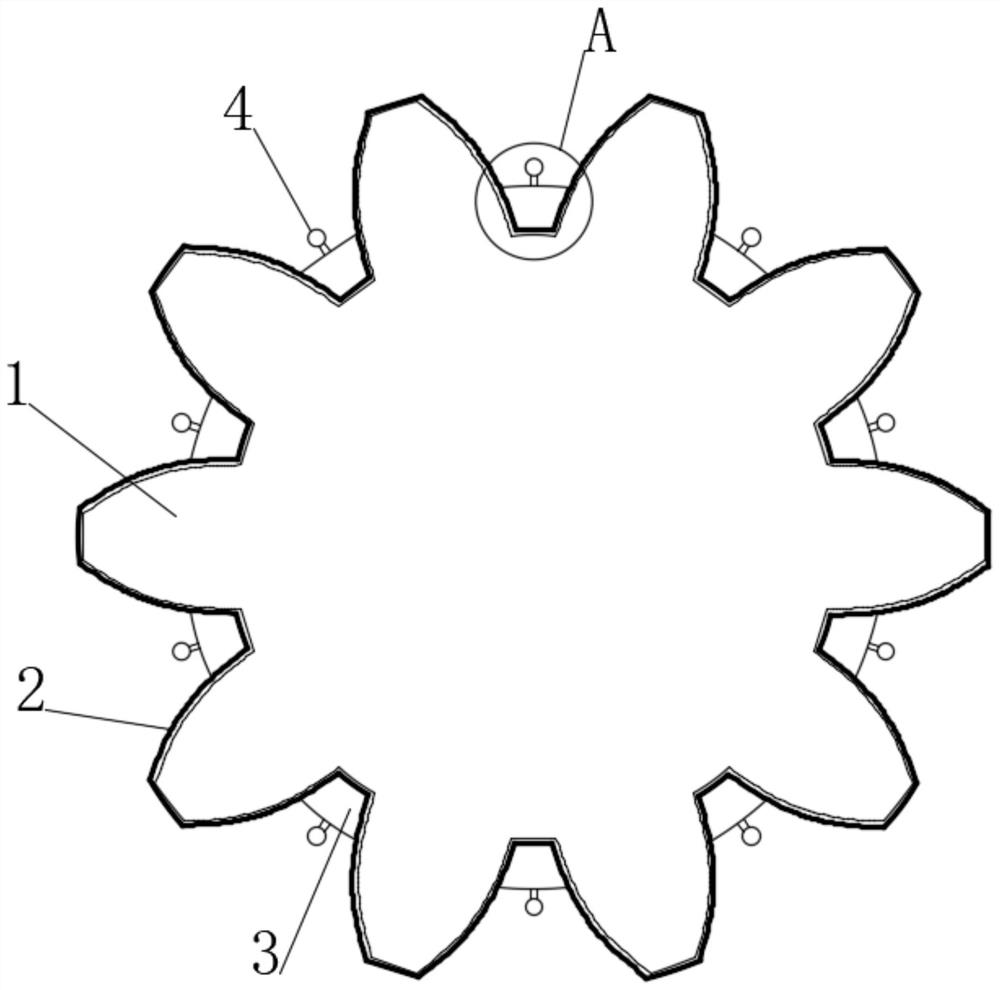

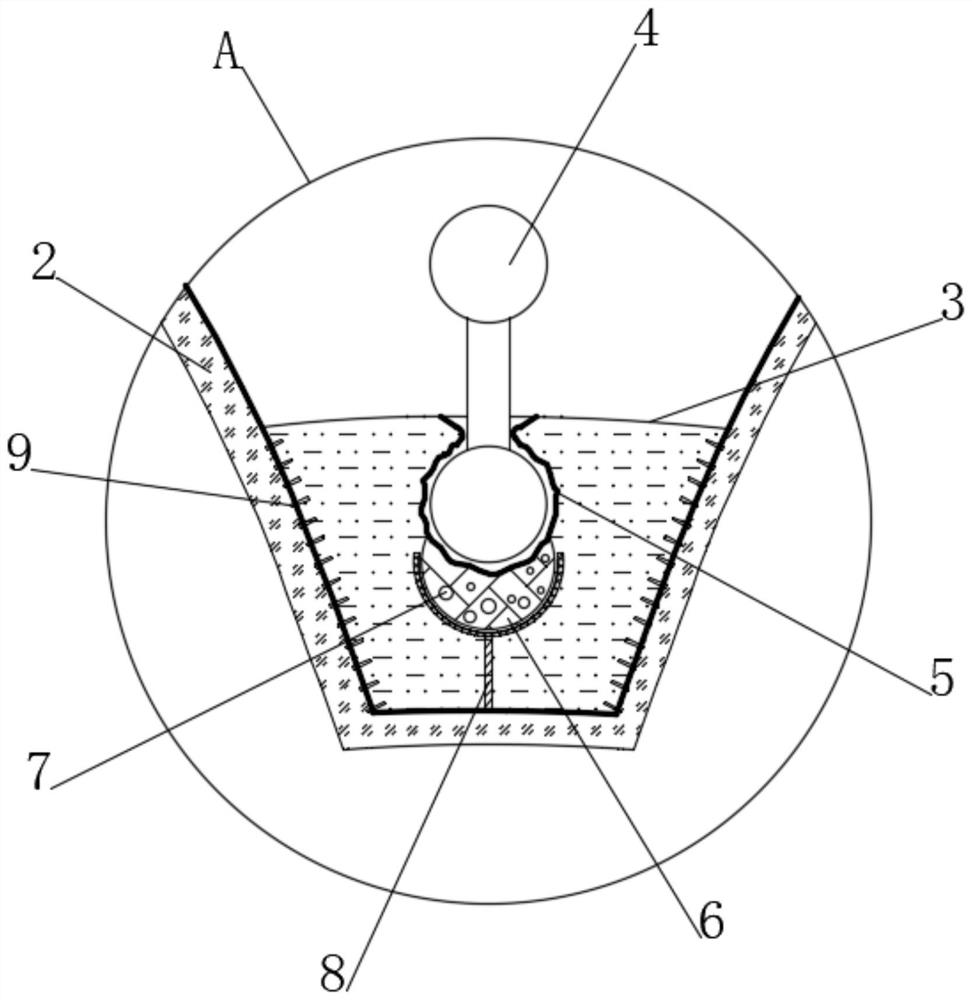

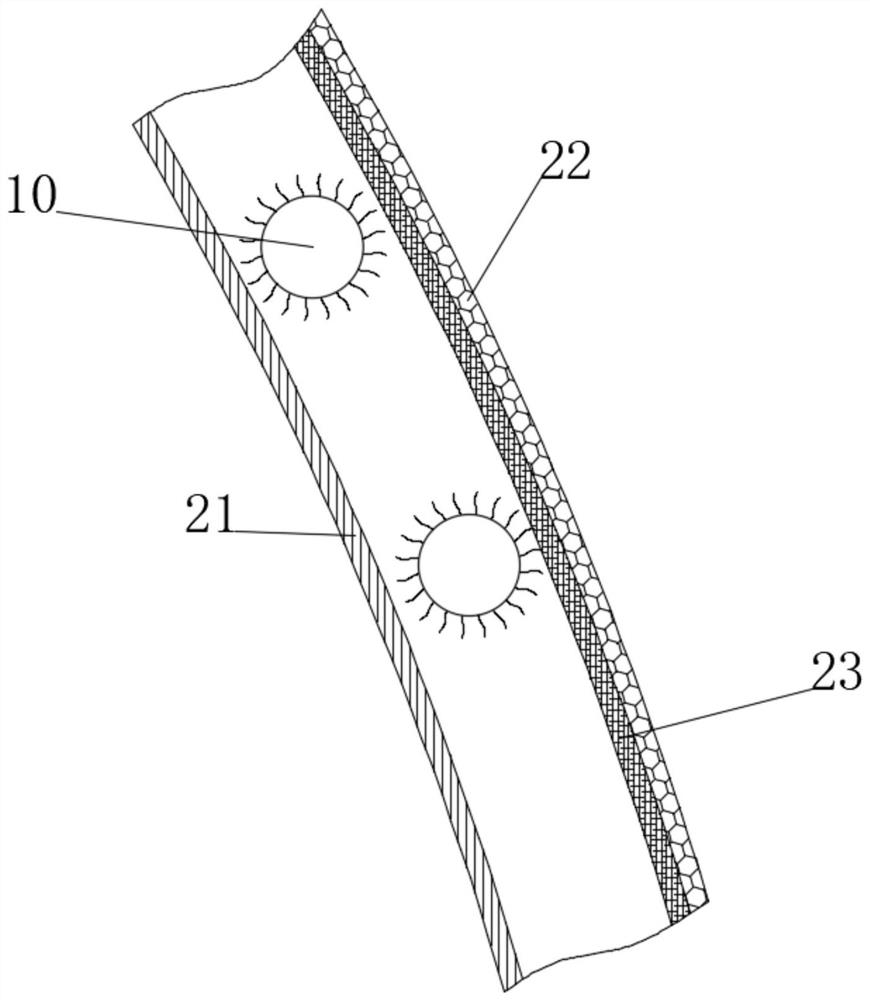

[0039] see Figure 1-2 , a tooth transfer self-maintenance gear, comprising a gear body 1 with a plurality of teeth, the outer end of the gear body 1 is wrapped with a self-maintenance layer 2, which is located outside the self-maintenance layer 2 between two adjacent teeth The transfer oil storage layer 3 is fixedly connected with the transfer oil storage layer 3, and the transfer oil storage layer 3 is filled with lubricating oil. The transfer oil storage layer 3 is embedded with a triggering bag 5, and the triggering bag 5 is movably connected with a double-headed contact rod 4, and the triggering bag 5 The lower end is fixedly connected with the pressure dynamic oil layer 6, and the bottom end of the self-maintenance layer 2 is fixedly connected with the support column 8. The support column 8 has a Y-shaped structure, so that the support column 8 can support the pressure dynamic oil layer 6. During the meshing and rotating process of the gears, when the teeth on the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com