A kind of waste paper fiber used for self-curing of cement-based materials and its preparation method

A cement-based material and waste paper fiber technology, applied in the field of building materials, can solve problems such as increased production costs, waste water and soil pollution, waste of wood resources, etc., and achieve the effects of improving water absorption capacity, reducing production costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

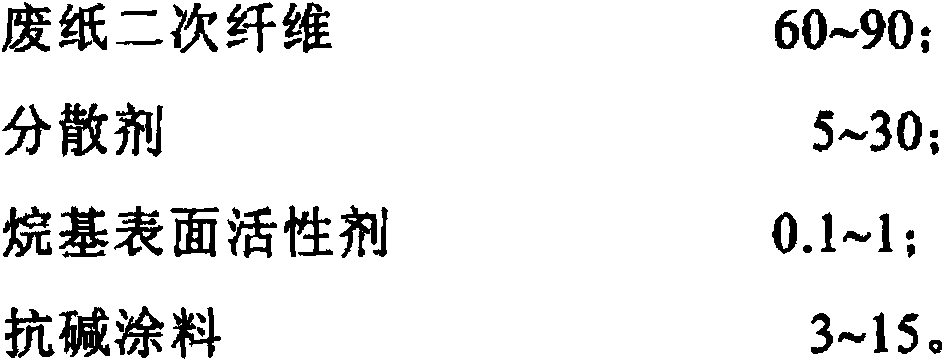

Embodiment 1

[0032] A waste paper fiber for self-curing of cement-based materials, which is prepared by using the following components and raw materials in parts by weight: waste paper secondary fiber 60, dispersant 5, alkyl surfactant 0.1, alkali-resistant coating 3, Among them, the secondary fiber of waste paper is obtained from scraps discarded by paper mills, waste book paper, wrapping paper, and urban household waste paper. The cellulose content is greater than 70%, and the water absorption rate is greater than 8 times its own gravity. The dispersant is kaolin or bentonite with a fineness greater than 5000 mesh. The surfactant is cetyl ammonium bromide or cetyl ammonium chloride. Anti-alkali coating is nano TiO 2 Hydrosol.

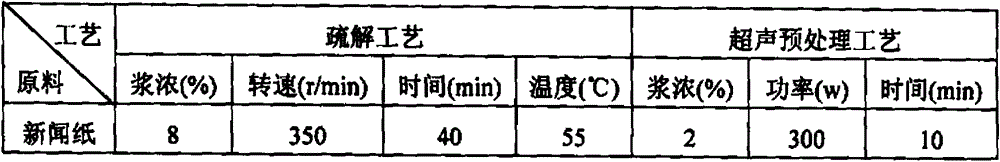

[0033] The preparation method of the waste paper fiber used for self-maintenance of cement-based materials adopts the following steps:

[0034] (1) Soak the waste paper completely in water for a period of time, pour it into a hydraulic pulper, control the pulp...

Embodiment 2

[0048] A waste paper fiber for self-curing of cement-based materials, which is prepared by using the following components and raw materials in parts by weight: waste paper secondary fiber 70; dispersant 8; alkyl surfactant 0.3; alkali-resistant coating 5, Secondary fibers of waste paper are obtained by thawing scraps discarded by paper mills, waste book paper, wrapping paper, and municipal waste paper. The content is greater than 70%, and the water absorption rate is greater than 8 times of its own gravity. The dispersant is kaolin or bentonite with a fineness greater than 5000 mesh. The surfactant is cetyl ammonium bromide or cetyl ammonium chloride. Anti-alkali coating is nano TiO 2 Hydrosol.

[0049] The preparation method of waste paper fibers used for self-maintenance of cement-based materials is the same as in Example 1, and the specific process parameters are as follows:

[0050] Table 3 Process parameters of waste paper treatment

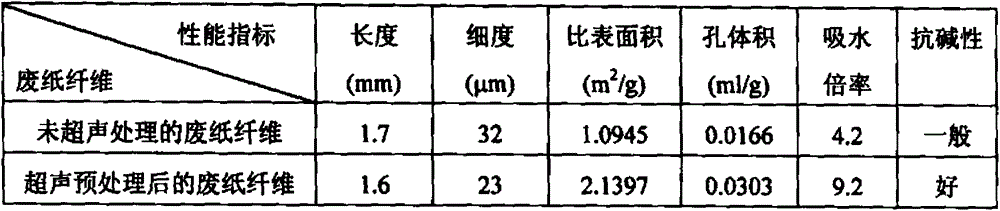

[0051]

[0052]

[0053] T...

Embodiment 3

[0058] A waste paper fiber used for self-curing cement-based materials, which is prepared by using the following components and raw materials in parts by weight: waste paper secondary fiber 90; dispersant 20; alkyl surfactant 0.6; alkali-resistant coating 10. Secondary fibers of waste paper are obtained by thawing scraps discarded by paper mills, waste book paper, wrapping paper, and municipal waste paper. The content is greater than 70%, and the water absorption rate is greater than 8 times of its own gravity. The dispersant is kaolin or bentonite with a fineness greater than 5000 mesh. The surfactant is cetyl ammonium bromide or cetyl ammonium chloride. Anti-alkali coating is nano TiO 2 Hydrosol.

[0059] The preparation method of waste paper fibers used for self-maintenance of cement-based materials is the same as in Example 1, and the specific process parameters are as follows:

[0060] Table 5 Process parameters of waste paper treatment

[0061]

[0062] Table 6 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com