Raw material treatment device for rumen bypass nicotinic acid coating and treatment method

A raw material processing and rumen-passing technology, applied in grain processing, chemical instruments and methods, solid separation, etc., can solve the problems of affecting the quality of production, inability to mix sufficiently, and not have, to ensure the effect of screening, fully effective The effect of mixing and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

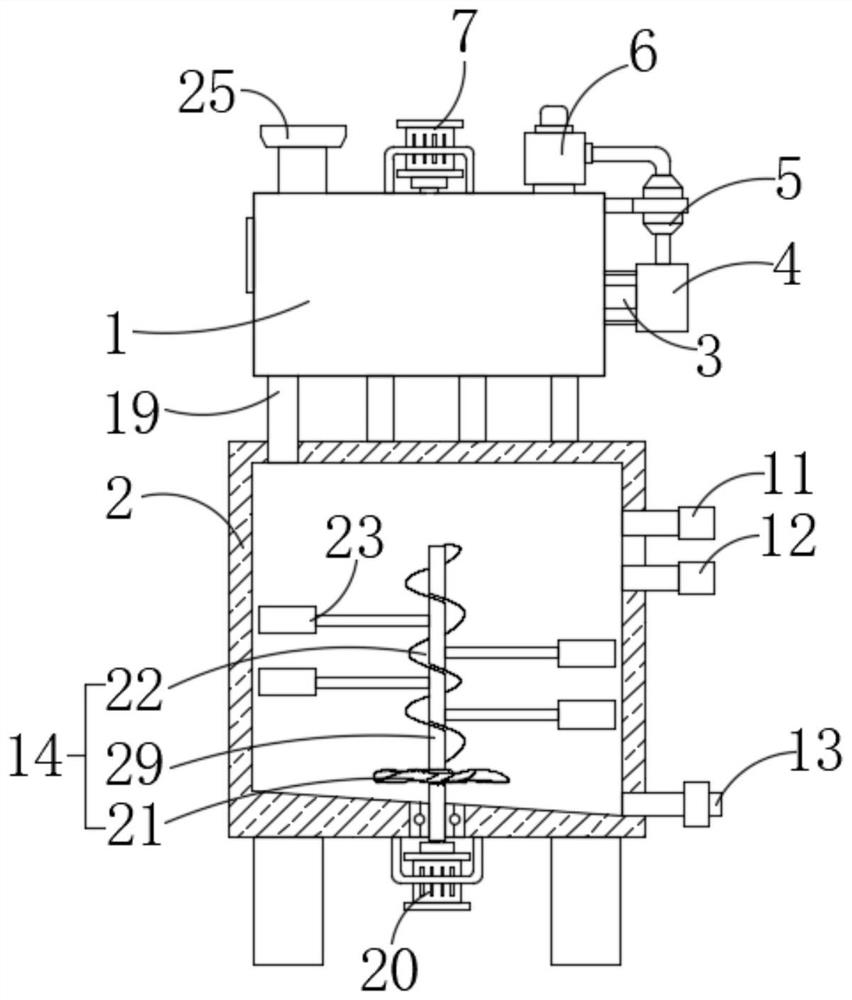

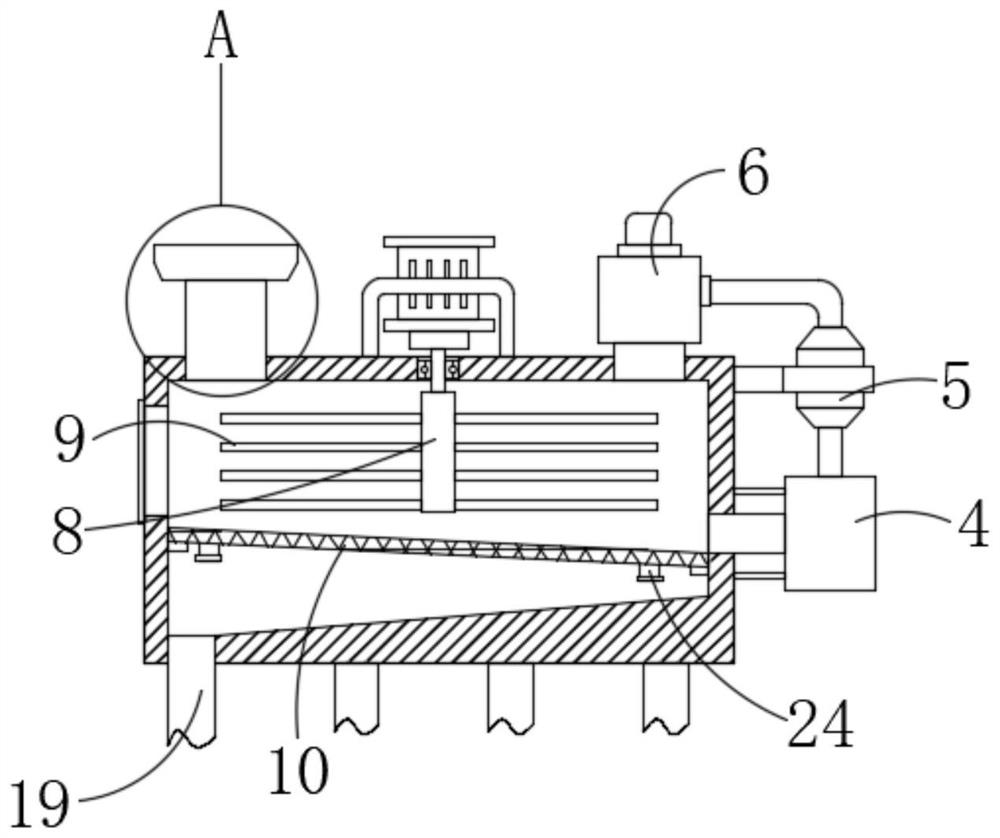

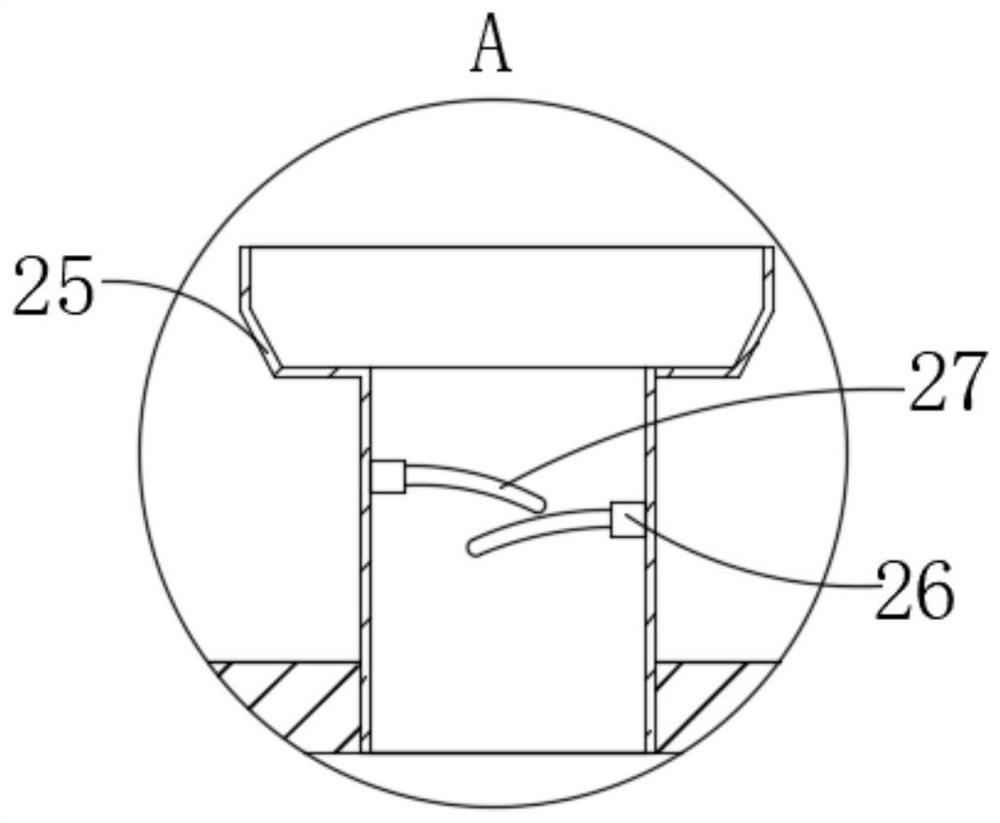

[0031] The present invention provides such as Figure 1-4 As shown, a rumen-passed niacin coating raw material processing device includes a raw material screening box 1 and a mixing box 2, the raw material screening box 1 is fixedly installed on the upper end of the mixing box 2 through a column, and the raw material screening box 1 A material return port 3 is provided, and the side wall of the raw material screening box 1 is fixedly connected with a material return box 4 through a connecting column. The material return port 3 communicates with the interior of the material return box 4. A pneumatic conveyor 5 is fixedly installed on the upper end of the return box 4, and the feeding end of the pneumatic conveyor 5 communicates with the inside of the return box 4 through a connecting pipe. The discharge end of the device 5 communicates with the crushing mechanism 6 through the connecting pipe, and the discharge end of the crushing mechanism 6 communicates with the inside of the...

Embodiment 2

[0037] On the basis of Embodiment 1, the crushing mechanism 6 includes a crushing box 15, a drive motor 16, a connecting column 17 and a crushing blade 18, the driving motor 16 is installed on the upper end of the crushing box 15, and the connecting column 17 is connected to the The output shaft of the drive motor 16 is connected, the crushing blade 18 is fixed on the connecting column 17, and the crushing blade 18 is located inside the crushing box 15, and the inside of the crushing box 15 and the upper end of the crushing box 15 discharge end are provided with a screen 28;

[0038]The mixing and stirring assembly 14 comprises a second driving motor 20, a second transmission rod 29, a stirring blade 21 and a stirring screw 22, the second driving motor 20 is fixed on the lower surface of the mixing box 2 by a fixed mount, the second transmission rod 29 is connected to the first The output shafts of the two driving motors 20 are connected, and one end of the second transmission ...

Embodiment 3

[0044] A processing method of a raw material processing device for niacin coating after passing through the rumen, comprising the following steps: S1. Adding the raw material of nicotinic acid to the inside of the raw material screening box through the raw material feeding pipe, and driving the crushing rod to crush the raw material of nicotinic acid through the first driving motor. The raw materials are crushed and sieved through the sieving filter plate;

[0045] S2. The niacin raw material that has passed the powder sieve enters the mixing box through the connecting pipe, injects the gelatinized starch through the first feeding pipe of the mixing box, and injects the hydroxypropyl methylcellulose dissolved in water through the second feeding pipe of the mixing box white;

[0046] S3, mixing the niacin raw material, the gelatinized starch, and the hydroxypropyl methylcellulose dissolved in water;

[0047] In step S1, when part of the niacin raw material does not pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com