Quantity limitation material supply mechanism for hair dyeing comb

A feeding mechanism and limited technology, applied in hair combs, devices for washing hair or scalp, hairdressing equipment, etc., can solve the problems of difficult output of hair dye, excessive output of hair dye, etc. Out-of-control, effective and uniform mixing, effect-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

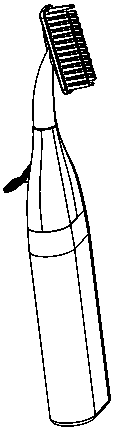

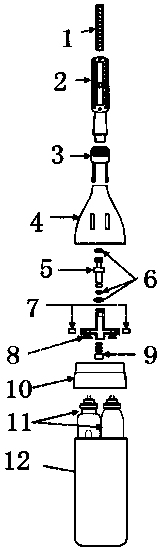

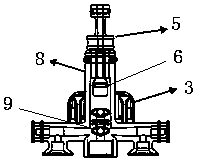

[0033] A hair dyeing comb with a feeding mechanism is a preferred embodiment of the present invention. Such as Figure 1-3 As shown: it includes comb rack 1, toothed comb handle 2, actuation switch 3, dyeing comb cover 4, limit rod 5, sealing ring 6, rubber particles 7, paste storage chamber 8, mixing device 9, fixing seat 10. Paste storage tank 11 and bottom cover 12. The paste storage tank 11 is replaceable.

[0034] In this embodiment, the comb tooth bar 1 can be installed on the toothed comb handle 2, especially in the middle of the outer comb teeth of the comb handle, and the height of the comb teeth of the comb tooth bar 1 is lower than that of the comb handle. The height of the outer comb teeth, so all the comb teeth form a groove shape made of comb teeth after the installation is completed; A special comb head structure of a hair dyeing comb, the comb teeth of the comb head form a groove shape, and at least the comb teeth located in the groove have the function of e...

Embodiment 2

[0044] A hair dyeing comb with a feeding mechanism, its structure is basically the same as that of Embodiment 1, the difference is that the limited feeding mechanism includes a cream storage chamber 8 and a limiting rod 5 . When there is only one kind of material to be output or the problem of mixing and stirring multiple kinds of materials is not considered, it is only necessary to adopt the limiting rod and the discharge channel of the paste storage chamber with the same structure as that of embodiment 1.

Embodiment 3

[0046] A limited feeding mechanism, which consists of the paste storage chamber, mixing and stirring device and limiting rod constitutes a limited feeding mechanism. Its paste storage room can have three or more material inlet ends, and the three kinds of materials are mixed with the same mixing and stirring device as in embodiment 1, and the limit rod 5 as in embodiment 1 is used to limit the materials output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com