Biomass gas internal combustion generator set

A technology for internal combustion generator sets and biomass gas, which is applied in the direction of internal combustion piston engines, combustion engines, combustion air/combustion-air treatment, etc., and can solve problems such as failure to start, low calorific value of biomass gas, and difficulty in mixing air completely. Achieve the effect of improving uniformity and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

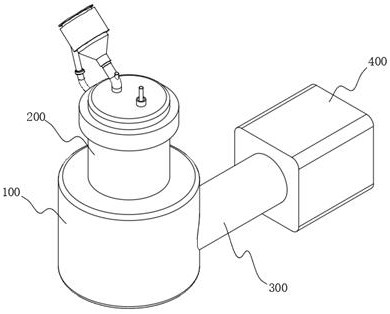

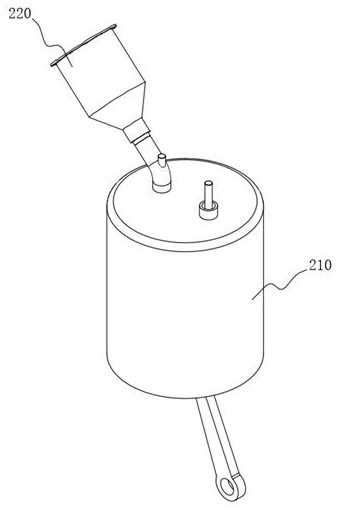

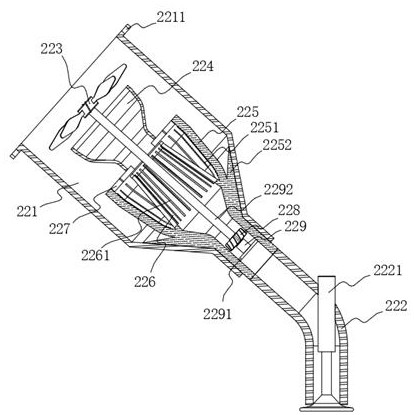

[0040] The first embodiment, this embodiment mainly discloses the working principle of the crank linkage mechanism, please refer to figure 2 As shown, the internal combustion mechanism 200 includes an outer housing 210, see Figure 7As shown, a combustion chamber is arranged inside the outer casing 210, and a piston 211 is slidably connected to the combustion chamber. A connection groove 2111 is opened at the bottom of the piston 211, and a connecting rod 212 is connected to the connection groove 2111 in rotation, and is driven by the pressure generated by the combustion of fuel in the combustion chamber. The piston 211 moves down, and then the lower part of the connecting rod 212 rotates and is connected with a crank. The connecting rod 212 that moves down drives the crank and the flywheel to rotate, and the connecting rod 212, the crank and the flywheel form a crank linkage mechanism, and then the piston 211 is driven Under the action of the inertia of the connecting rod 21...

no. 2 example

[0048] For a second example, see Figure 5-Figure 7 As shown, the outer casing 210 is provided with a hot air delivery group 230, the hot air delivery group 230 includes a heat collection ring 231, and the heat collection cavity 231A is formed by closing the heat collection ring 231 and the outer casing 210, and the hot air delivery group 230 also includes The conduction ring 232, the conduction ring 232 is arranged outside the outer tube body 221, and the conduction cavity 232A is formed by closing between the conduction ring 232 and the outer tube body 221, and the transmission pipe 233 is arranged between the heat collection ring 231 and the conduction ring 232, and the transmission pipe 233 A negative pressure pump 234 is provided so that the heat generated during combustion in the combustion chamber is conducted to the heat collecting chamber 231A by the outer wall of the outer shell 210, and then the heat is transferred to the conduction chamber 232A through the transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com