Heat-preservation material mixing device

A technology of mixing device and thermal insulation material, which is applied to mixers with rotary stirring devices, mixers, transportation and packaging, etc., can solve the problems of uneven mixing of thermal insulation materials, long stirring time, etc. , Improve work efficiency and ensure the effect of standardization

Inactive Publication Date: 2018-05-22

宁波得晴电器科技有限公司

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a thermal insulation material mixing device to solve the problems of uneven mixing of thermal insulation materials and excessively long stirring time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

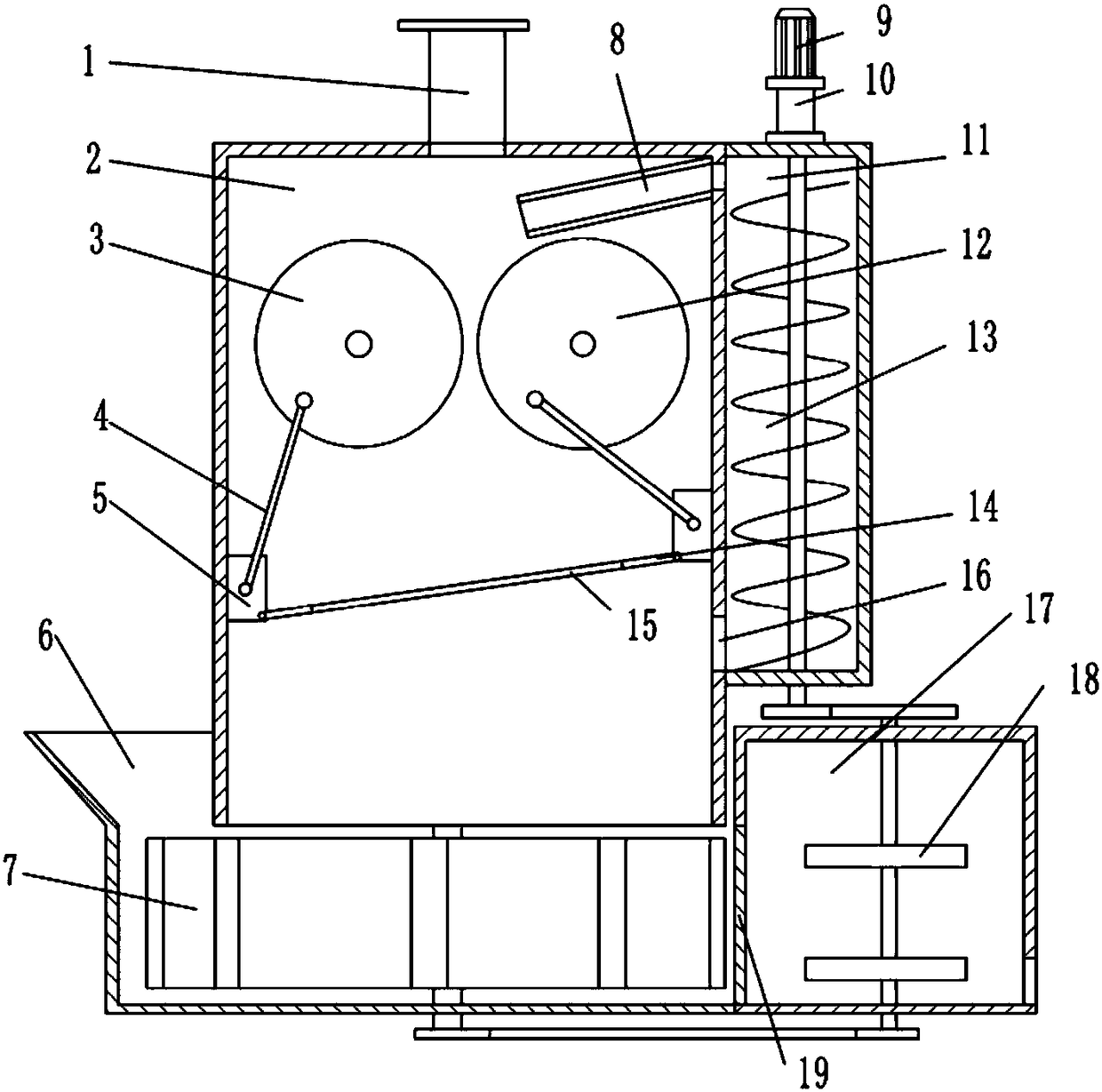

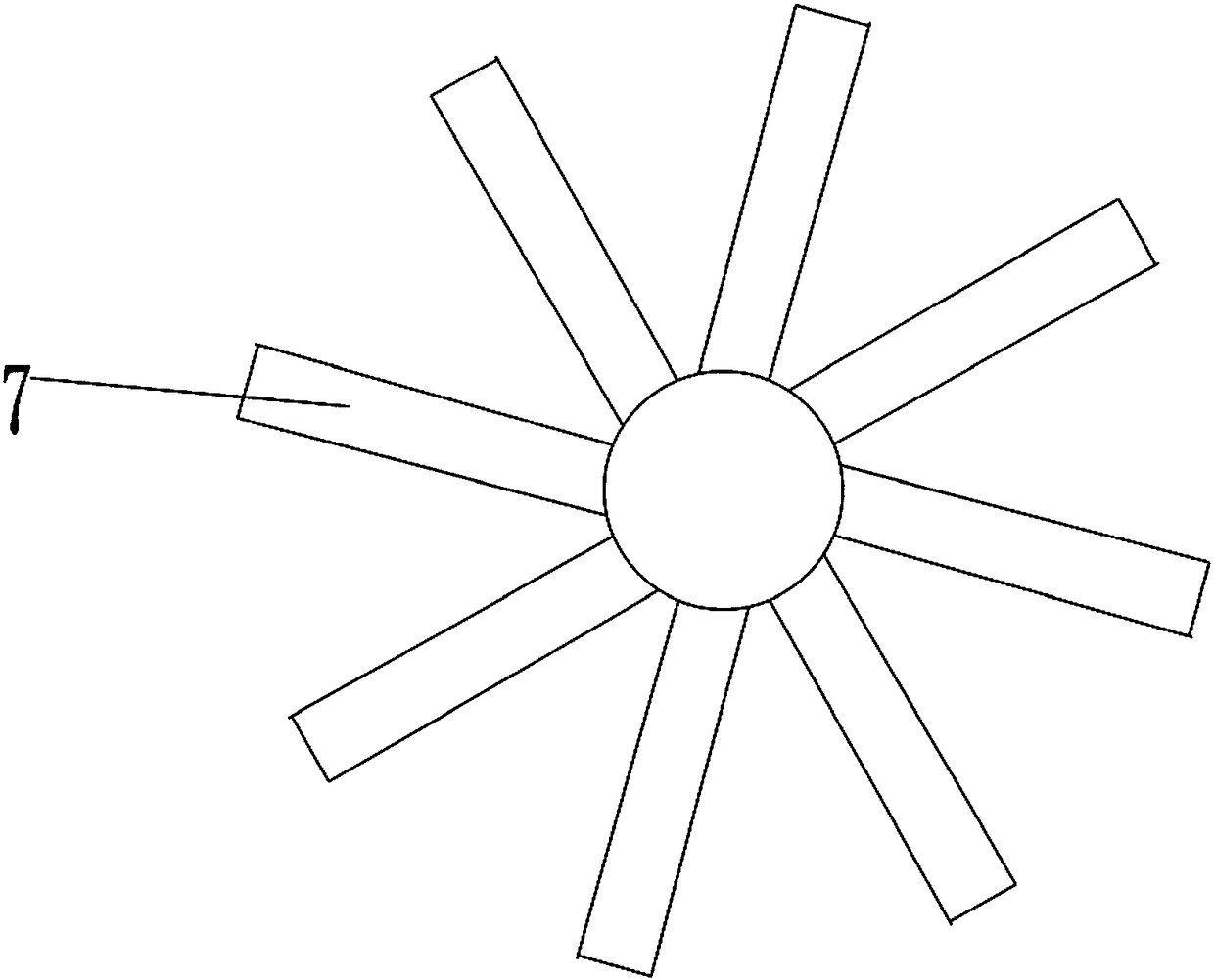

The invention belongs to the technical field of material mixing devices and in particular discloses a heat-preservation material mixing device which comprises a crushing part, a conveying part and a mixing part, wherein a first crushing roller and a second crushing roller are arranged inside a crushing bucket to crush raw materials; the first crushing roller, the second crushing roller, connectingrods and sliding blocks form a bias crankshaft sliding block mechanism; a filtering net is arranged between the two sliding blocks; a material circulation hole is formed in a side wall when the sliding blocks are moved to a lowest point; a circulation bucket with spiral conveying blades is mounted outside the material circulation hole; the circulation bucket is communicated with the upper part ofa crushing bucket; the conveying part is communicated with the lower end of the crushing part; the conveying part comprises a conveying bucket; a second feeding hole and shifting blades are arrangedinside the conveying bucket; the mixing part is communicated with the conveying part; the mixing part comprises a mixing bucket; stirring blades and a discharge hole are arranged inside the mixing bucket. By adopting the scheme of the invention, the problems that heat-preservation materials are not uniformly mixed and the stirring time is too long, are solved.

Description

technical field [0001] The invention belongs to the technical field of mixing devices, and in particular relates to a mixing device for thermal insulation materials. Background technique [0002] In our daily life, maintaining a constant indoor temperature will make us feel more comfortable. For example, heating in winter and cooling in summer can only be produced by consuming fossil resources. In the air-conditioning season, building power consumption also accounts for a large proportion. Therefore, indoor thermal insulation plays a decisive role. Thermal insulation wall panels It can effectively insulate the interior. [0003] Existing thermal insulation wallboards are all made of thermal insulation materials, which are usually mixed with various powders. Before use, the various insulating materials need to be fully mixed so that they are evenly mixed. At present, insulation material mixers or agitators are generally used for mixing, but because different raw materials ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F13/10B01F7/18B02C4/02B02C4/28B02C4/32B02C4/42B02C23/16

CPCB02C4/02B02C4/28B02C4/32B02C4/42B02C23/16B02C2023/165B01F27/90B01F33/83B01F33/831B01F33/83612

Inventor 王健

Owner 宁波得晴电器科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com