Die-cast air cylinder cover of air-cooled single-cylinder diesel engine

A technology for cylinder heads and diesel engines, applied in the directions of cylinder heads, cylinders, mechanical equipment, etc., can solve the problems of poor diesel engine performance, poor flow performance, and inability to change the cross-sectional shape, and achieve increased flow coefficient, reduced emissions, and air passage flow characteristics. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

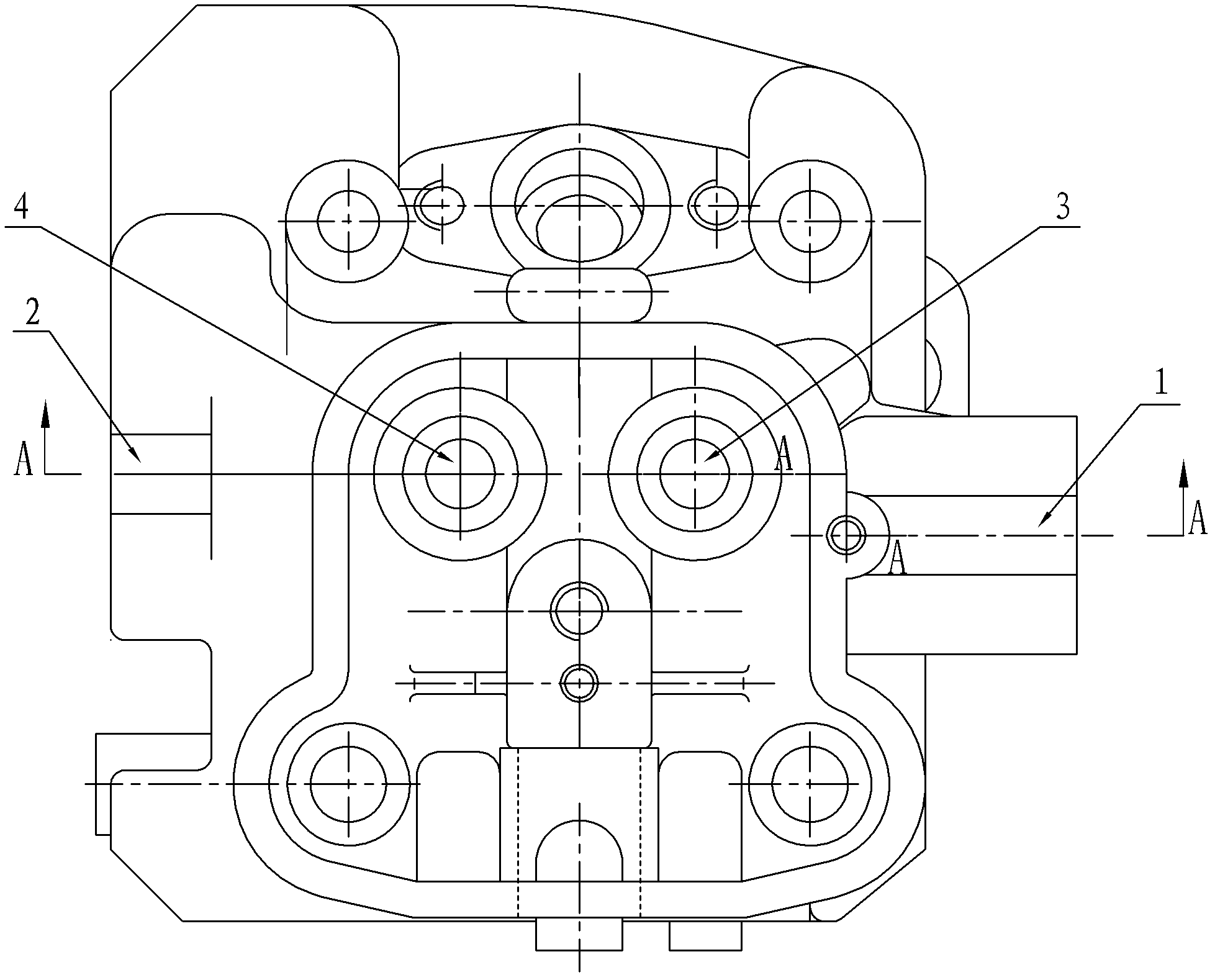

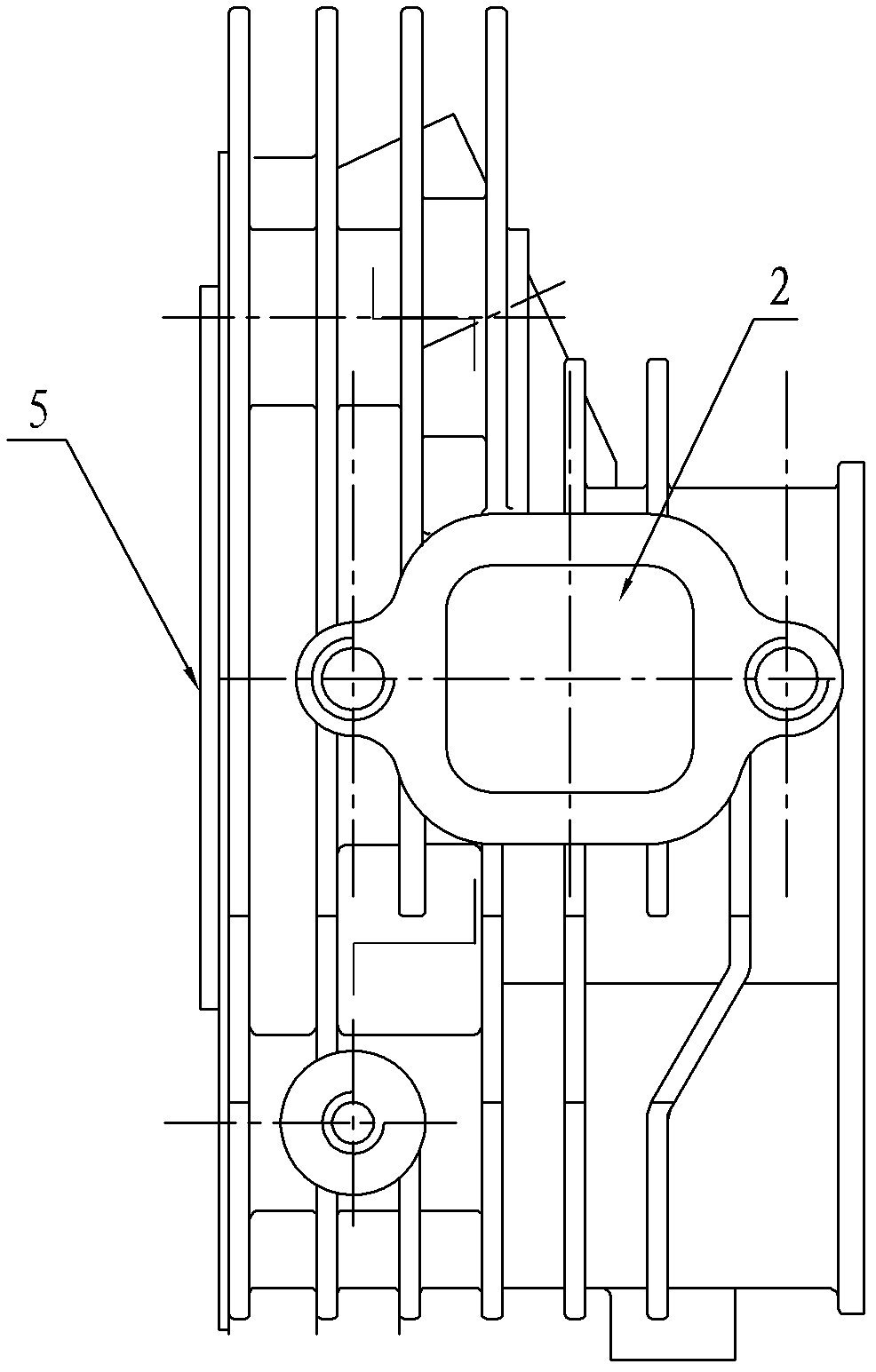

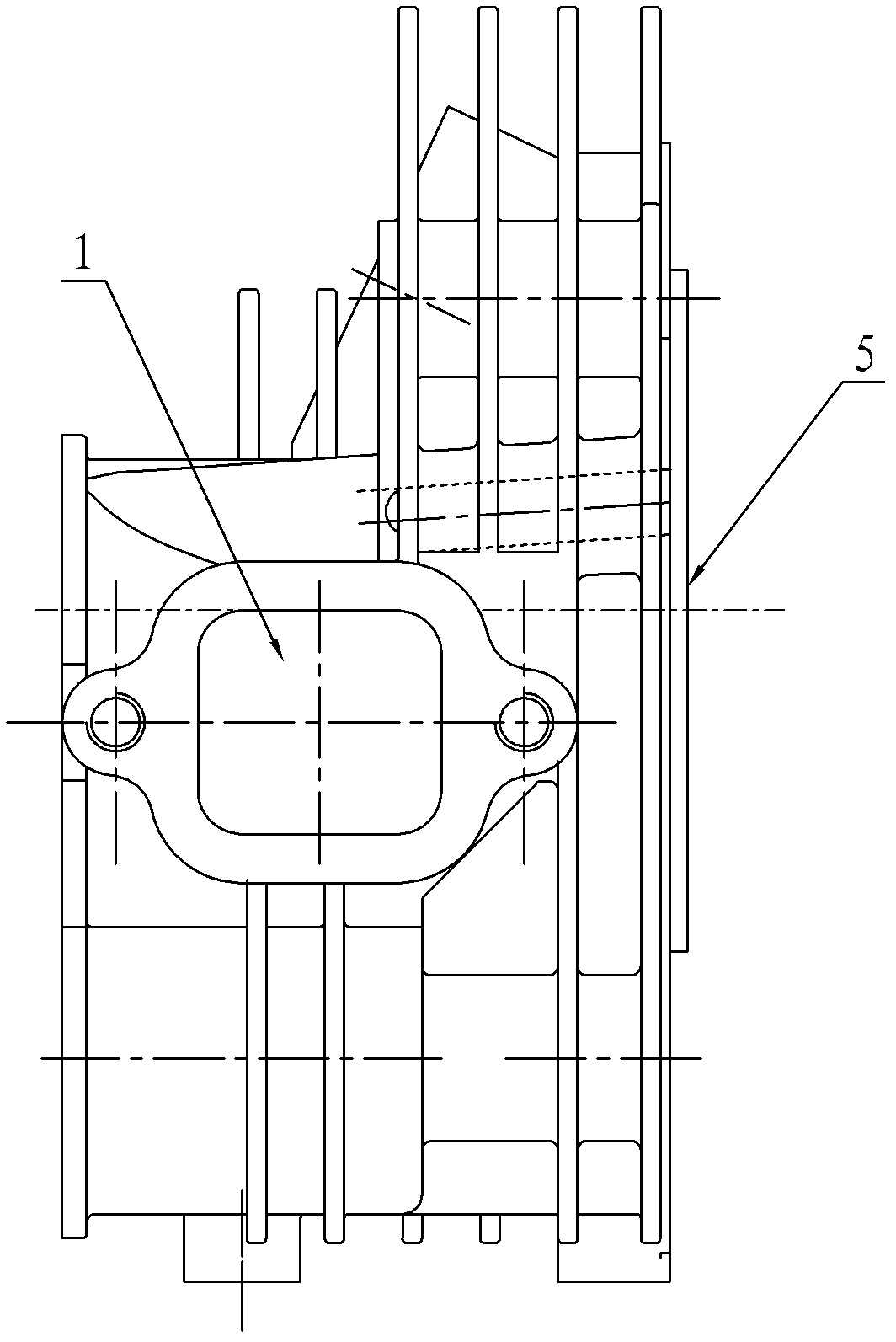

[0022] Embodiment 1: A kind of single-cylinder air-cooled diesel engine die-casting cylinder head, such as Figure 1 ~ Figure 4 As shown, it includes an intake port 1 and an exhaust port 2. The intake port 1 is composed of an intake port casting hole section 11 and an intake port processing hole 12. The intake port processing hole 12 is the same as the intake valve guide rod hole 3. Shaft, the shape of the cross-section of the air inlet casting hole section 11 is a square with rounded corners, and the area gradually shrinks along the center line, and its draft angle is 2%. The air inlet casting hole section 11 and the air inlet The machining hole sections 12 are geometrically intersected to form the turning curve of the air inlet 1. At the intersection of the two, the maximum cross-sectional size of the air inlet casting hole section 11 is equal to the diameter of the air inlet machining hole 12; The distance between the bottom surface 6 of the intake port machining hole and t...

Embodiment 2

[0023] Embodiment 2: In this embodiment, the shape of the cross-section of the casting hole section 11 of the air intake duct and the casting hole section 21 of the exhaust duct is a combination of a rectangle and a semicircle, with the rectangle at the top and the semicircle at the bottom.

Embodiment 3

[0024] Embodiment 3: In Embodiment 1, the bottom surface 6 of the intake port processing hole coincides with the lower end surface 7 of the guide rod hole of the intake valve; the bottom surface 8 of the exhaust port processing hole coincides with the lower end surface 9 of the guide rod hole of the exhaust valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com