Lithium ion conducting gel film containing porous polymer framework and preparation method thereof

A porous polymer, conductive gel technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of low electrolyte absorption rate and retention rate, low conductivity, poor strength, etc., and achieve improved mechanical strength, Low environmental requirements and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] 1. Preparation of Porous Membrane Skeleton

[0054] The solution phase inversion method is used to prepare porous membranes, and the modification of polyvinylidene fluoride and polyethersulfone is realized by adding polypropylene glycol in the casting solution. The preparation method includes the following steps in sequence: (1) preparing the casting solution: adding dihydroxy Polypropylene glycol, polyvinylpyrrolidone, water, solvent and polyvinylidene fluoride or polyether sulfone are mixed and dissolved, and degassed to obtain a casting solution; (2) Scraping liquid film: scrape the casting solution on a stainless steel plate or steel strip to form Liquid film; (3) curing into film: immerse the stainless steel plate with liquid film in a coagulation bath to solidify into film; (4) cleaning and drying.

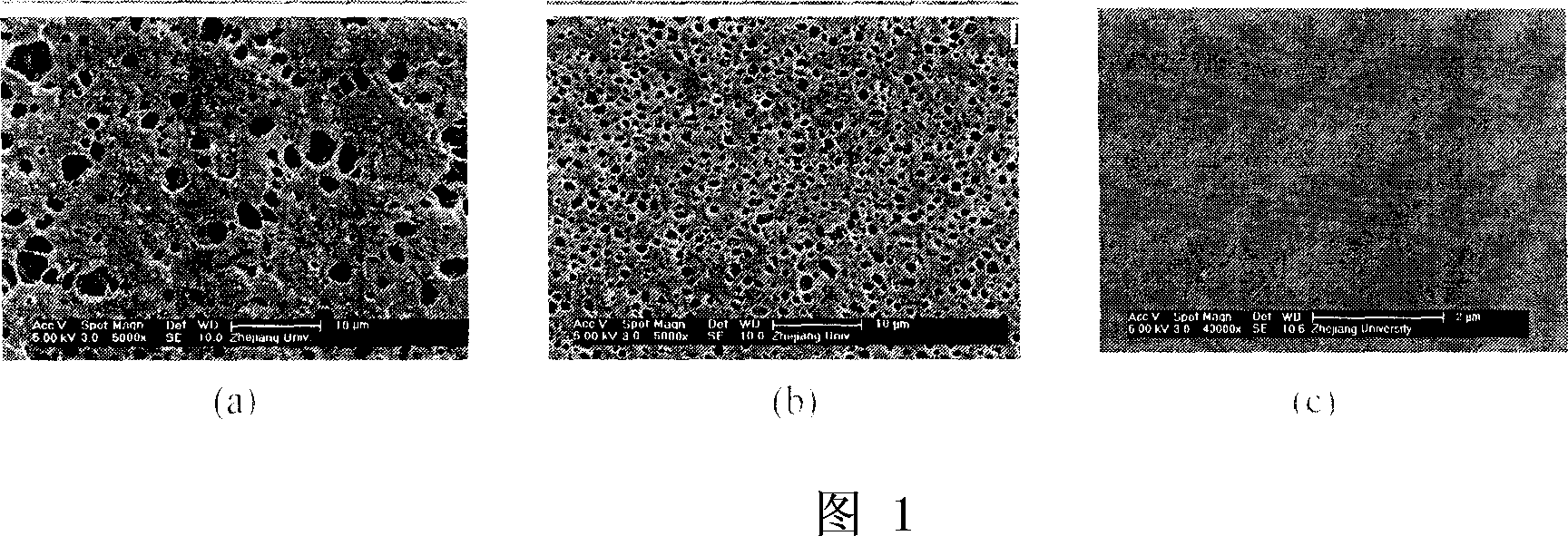

[0055] A porous membrane suitable for using gel membrane as a skeleton needs to have continuous microporous channels, symmetrical structure, high porosity on the memb...

Embodiment 1

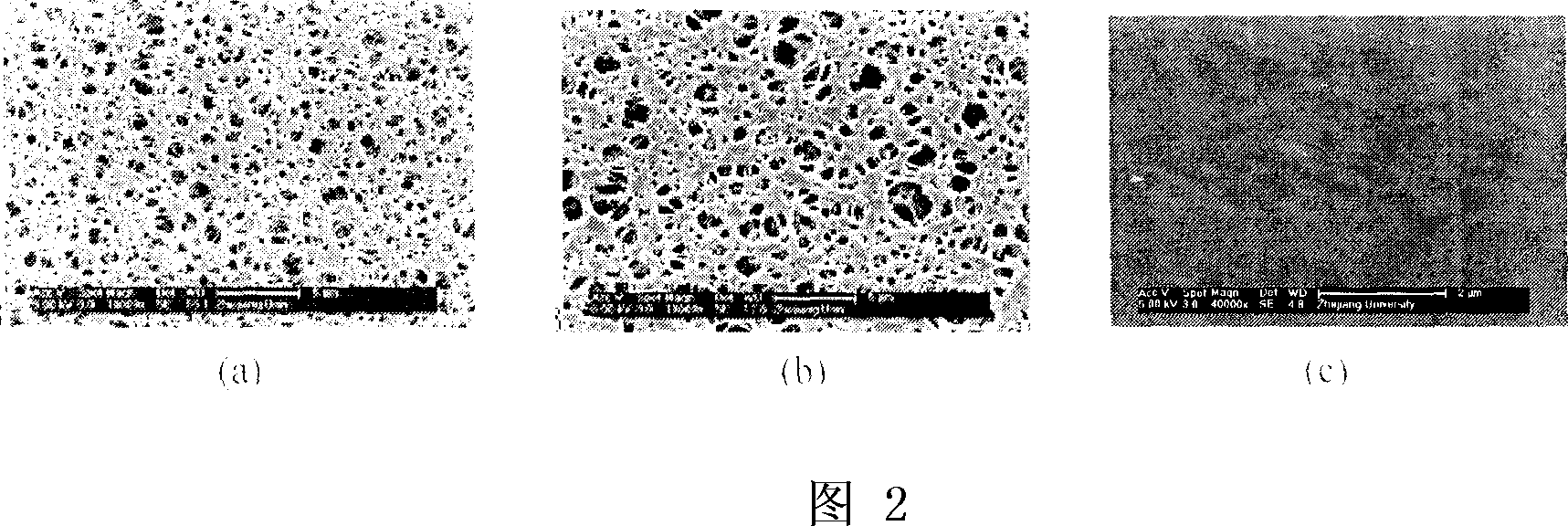

[0091] Example 1: The various implementation conditions and the structure and performance of the obtained lithium ion conductive gel membrane are shown in Table 1.

[0092] Casting solution

Embodiment 2

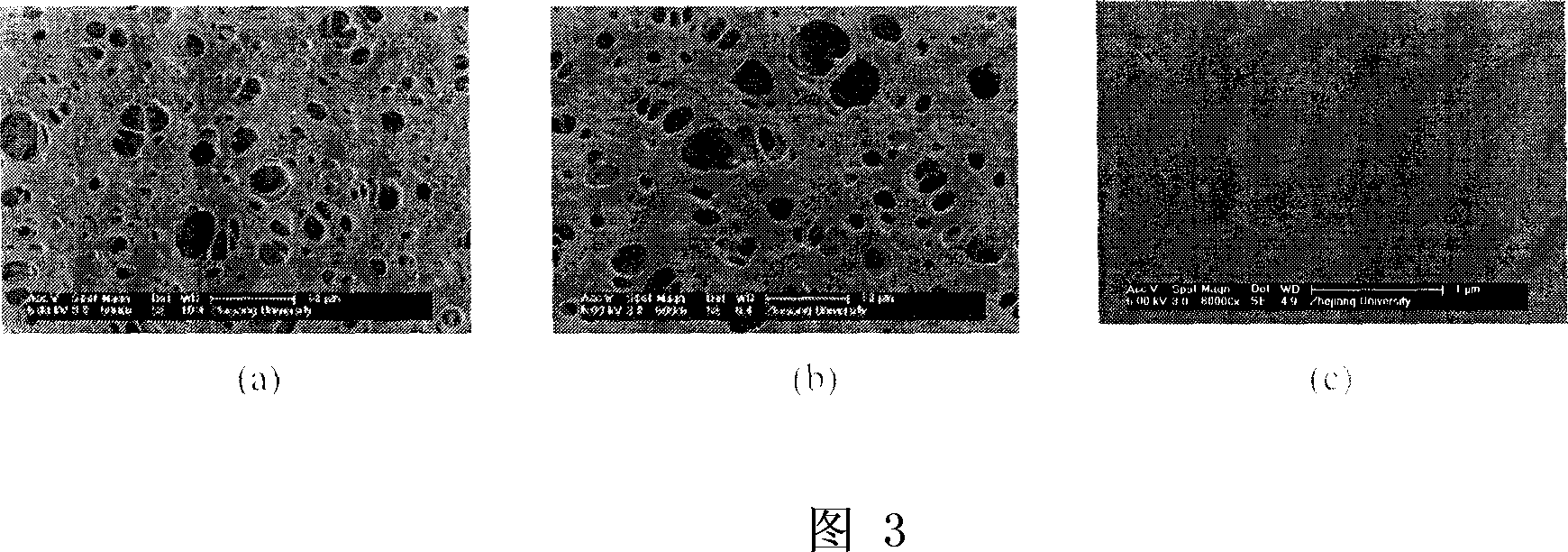

[0093] Example 2: The various implementation conditions and the structure and performance of the obtained lithium ion conductive gel membrane are shown in Table 2.

[0094] Casting solution

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com