Full element formula fertilizer and its preparing method and use

An all-element, formula fertilizer technology, applied in the direction of fertilizer mixture, application, fertilization equipment, etc., can solve the problems of not being able to fully develop, not fully considering the interaction of nutrient elements, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

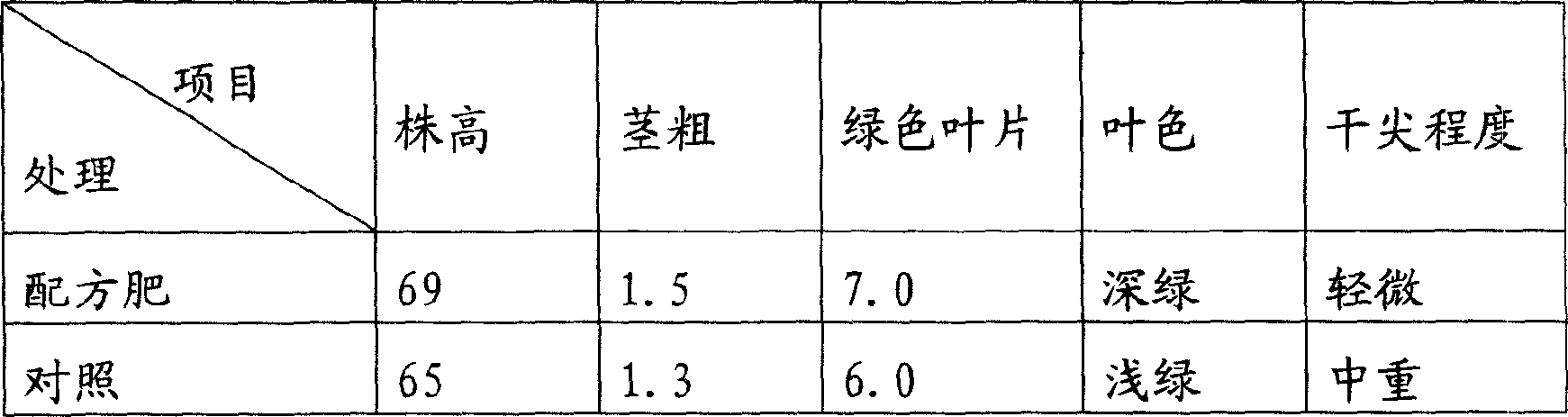

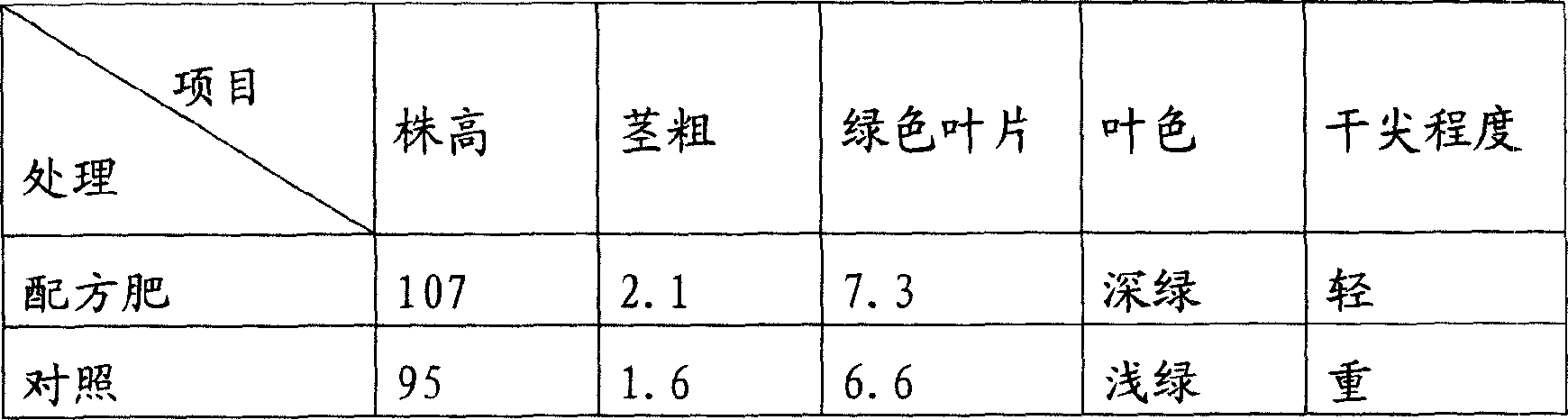

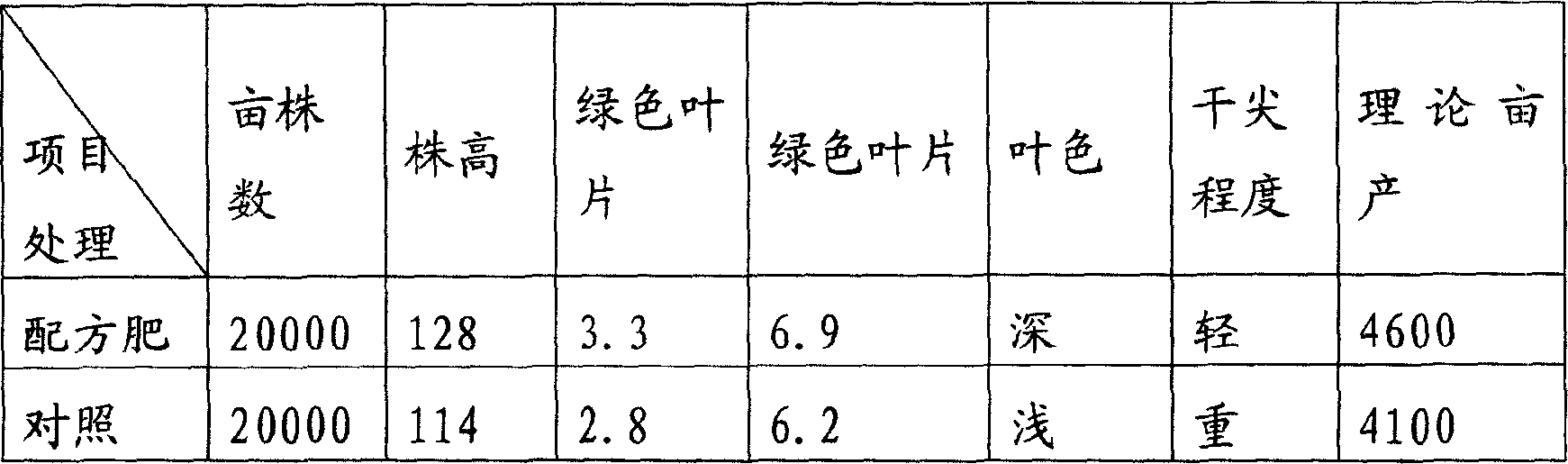

Examples

example 1

[0015] Prepare 100 kg of all-element formula fertilizer, consisting of: 20 kg of nitrogen fertilizer, 15 kg of phosphate fertilizer, 15 kg of potassium fertilizer, 20 kg of calcium fertilizer, 15 kg of magnesium fertilizer, 6 kg of silicon fertilizer, 2 kg of sulfur fertilizer, 2 kg of zinc fertilizer, and 5 kg of humic acid.

[0016] Described nitrogen fertilizer is urea; Described phosphate fertilizer is monoammonium phosphate; Described potassium fertilizer is potassium sulfate; Described calcium fertilizer is calcium oxide; Described magnesium fertilizer is magnesium sulfate and magnesium oxide, wherein magnesium sulfate accounts for 10 The magnesium oxide accounts for 5 kilograms; the silicon fertilizer is silicon dioxide; the sulfur fertilizer is sulfur; the zinc fertilizer is zinc sulfate; and the humic acid is peat.

[0017] The specific preparation process is: first mix nitrogen fertilizer, phosphorus fertilizer and potassium fertilizer according to the above ratio fo...

example 2

[0019] All the other are the same as embodiment 1, but described nitrogen fertilizer is ammonium sulfate; Described phosphate fertilizer is potassium dihydrogen phosphate; Described potash fertilizer is potassium chloride; Described calcium fertilizer is calcium carbonate; Described magnesium fertilizer is sulfuric acid magnesium and magnesium oxide; the silicon fertilizer is calcium metasilicate; the sulfur fertilizer is phosphogypsum; the zinc fertilizer is zinc chloride; and the humic acid is weathered coal.

[0020] The main advantages of this formula fertilizer are as follows:

[0021] 1. It is universal, applicable to all plants and any soil, can enhance the stress resistance of plants, will not produce diseases and insect pests caused by the use of simple elements, and has resistance to external infection of diseases and insect pests.

[0022] 2. Improve the quality of crops and restore the natural sweetness of crops such as grain, vegetables, melons and fruits, fruit t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com