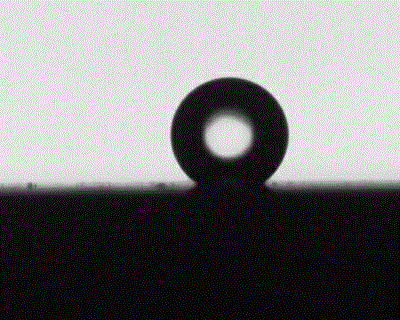

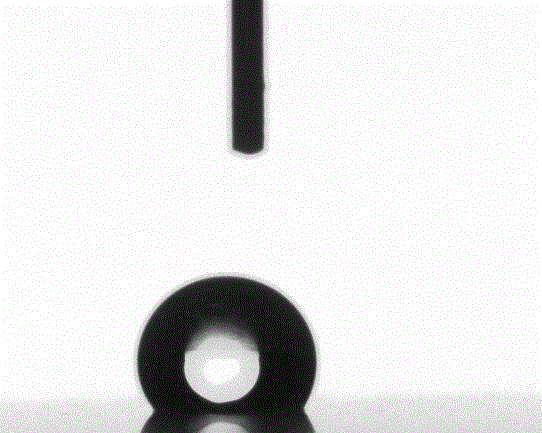

Semiconductor superhydrophobic paint and preparation method thereof

A super-hydrophobic coating, semiconductor technology, applied in conductive coatings, polyester coatings, polyurea/polyurethane coatings, etc., to achieve the effects of easy construction, improved flashover voltage, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The weight distribution ratio of each component raw material of the present invention is as follows:

[0039]

[0040] Among them, the low surface substances are perfluorobutyric acid, fluorochlorovaleric acid, sodium fluorine-containing alkyl sulfonate, perfluorooxaamide quaternary ammonium salt, triglyceride of fluorine-containing acid, fluorine-containing tetrachlorophthalate, One or more components of perfluorooctyl alcohol and fluoroalkyl silicone;

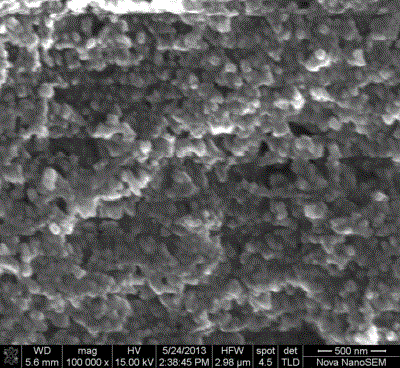

[0041] Wherein the hydrophobic nanoparticles are one or more compositions of chlorosilane-modified synthetic silica particles or hexamethyldisilazane-modified synthetic silica particles;

[0042] Wherein the organic solvent is one or more of ethyl acetate, benzene, toluene, xylene, pentane, hexane, octane, cyclohexane, cyclohexanone, toluene cyclohexanone;

[0043] Wherein the thermoplastic resin is one or more of acrylic resin, polyurethane resin, alkyd resin, polydimethylsiloxane, polystyrene;

[0044] Wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com