Preparation method of antifogging and self-cleaning nano material

A nanomaterial, self-cleaning technology, applied in mixing methods, chemical instruments and methods, mixers with rotary stirring devices, etc., can solve the problems of loss of material properties, reduced use effect, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

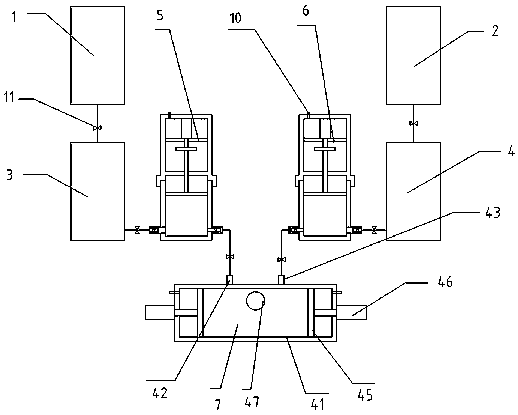

[0092] A preparation method of anti-fog, self-cleaning nanometer material, comprises the following steps:

[0093] (1) Preparation of component A:

[0094] ① Weigh 80 parts of absolute ethanol, 0.5 part of nano-titanium dioxide, 10 parts of acetone, 3 parts of silicone oil, 4 parts of carboxymethyl cellulose, and 0.8 part of platinum nanoparticles by weight as raw materials;

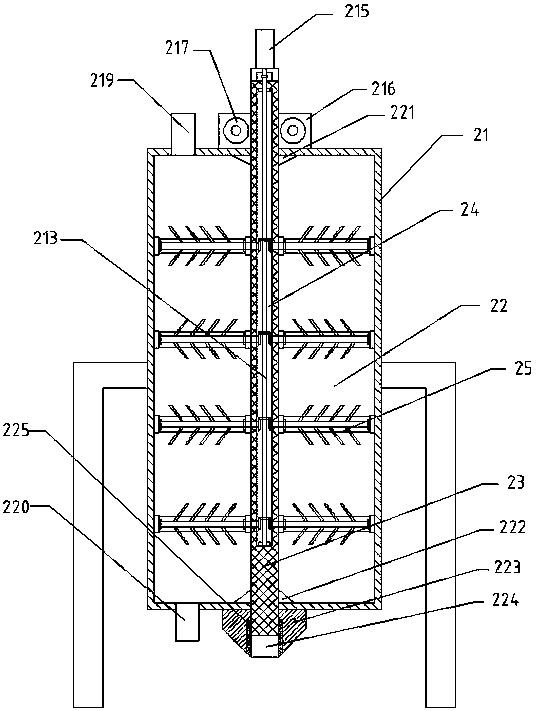

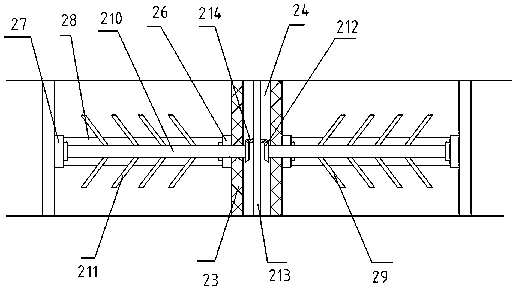

[0095] ②Add the raw materials of component A into the first stirring device for mixing to obtain solution A;

[0096] ③ Store solution A in the first storage tank;

[0097] (2) Preparation of component B:

[0098] ① Weigh 80 parts of deionized water, 5 parts of butane, 1 part of nano silicon dioxide, 3 parts of ethylene glycol, 2 parts of silicone oil, and 0.5 part of graphene nanosheets as raw materials in parts by weight;

[0099] ② Add the raw materials of component B to the second stirring device for mixing to obtain solution B;

[0100] ③ Store solution B in the second storage tank;

[0101] (3...

Embodiment 2

[0107] A preparation method of anti-fog, self-cleaning nanometer material, comprises the following steps:

[0108] (1) Preparation of component A:

[0109] ① Weigh 90 parts of absolute ethanol, 1 part of nano-titanium dioxide, 15 parts of acetone, 6 parts of silicone oil, 5 parts of carboxymethyl cellulose, and 2 parts of platinum nanoparticles by weight as raw materials;

[0110] ②Add the raw materials of component A into the first stirring device for mixing to obtain solution A;

[0111] ③ Store solution A in the first storage tank;

[0112] (2) Preparation of component B:

[0113] ①Weigh 90 parts of deionized water, 8 parts of butane, 3 parts of nano silicon dioxide, 6 parts of ethylene glycol, 5 parts of silicone oil, and 2 parts of graphene nanosheets as raw materials in parts by weight;

[0114] ② Add the raw materials of component B to the second stirring device for mixing to obtain solution B;

[0115] ③ Store solution B in the second storage tank;

[0116] (3) Afte...

Embodiment 3

[0122] A preparation method of anti-fog, self-cleaning nanometer material, comprises the following steps:

[0123] (1) Preparation of component A:

[0124] ①Weigh 100 parts of absolute ethanol, 2 parts of nano-titanium dioxide, 20 parts of acetone, 8 parts of silicone oil, 6 parts of carboxymethyl cellulose, and 3 parts of platinum nanoparticles by weight as raw materials;

[0125] ②Add the raw materials of component A into the first stirring device for mixing to obtain solution A;

[0126] ③ Store solution A in the first storage tank;

[0127] (2) Preparation of component B:

[0128] ① Weigh 100 parts of deionized water, 12 parts of butane, 5 parts of nano silicon dioxide, 10 parts of ethylene glycol, 6 parts of silicone oil, and 4 parts of graphene nanosheets as raw materials in parts by weight;

[0129] ② Add the raw materials of component B to the second stirring device for mixing to obtain solution B;

[0130] ③ Store solution B in the second storage tank;

[0131] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com