Preparation method of modified HIPS composite material

A composite material and modification technology, which is applied in the field of preparation of modified HIPS composite materials, can solve the problems of easy fogging, affecting product use effect, easy adhesion of oil stains, etc., and achieves long-term anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 of the present invention discloses a preparation method of a modified HIPS composite material, and the adopted technical scheme is as follows:

[0030] A preparation method of modified HIPS composite material, comprising the following steps:

[0031] Preparation of HIPS prefabricated materials, injection molding;

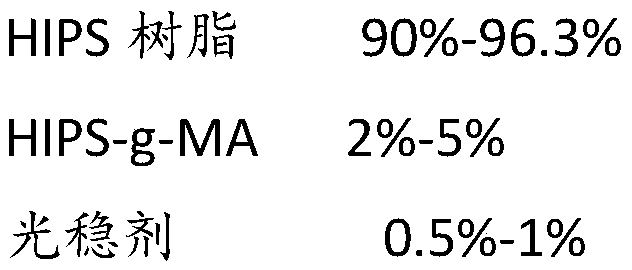

[0032] The component raw materials of the prefabricated materials are calculated by weight percentage and consist of the following raw materials:

[0033]

[0034] Mix each component in a high-speed mixer for 7 minutes; use a twin-screw extruder to melt and extrude the mixed material and granulate. The process conditions are: the aspect ratio of the twin-screw extruder is 38, and the screw barrel The temperature is 180-240°C, the screw speed is 420r / min, and the pressure is 15MPa;

[0035] The HIPS prefabricated material prepared above was injection molded into a sample with a surface area of 20 cm 2 1.6 g of ferrous ammonium sulfate is a...

Embodiment 2

[0040] Embodiment 2 of the present invention discloses a preparation method of a modified HIPS composite material, and the adopted technical scheme is as follows:

[0041] A preparation method of modified HIPS composite material, comprising the following steps:

[0042] Preparation of HIPS prefabricated materials, injection molding;

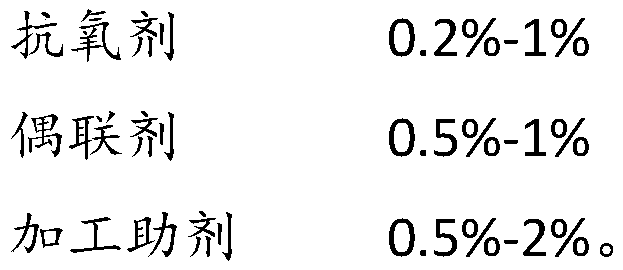

[0043] The component raw materials of the prefabricated materials are calculated by weight percentage and consist of the following raw materials:

[0044]

[0045]

[0046] Mix each component in a high-speed mixer for 5 minutes; use a twin-screw extruder to melt and extrude the mixed material and granulate. The process conditions are: the aspect ratio of the twin-screw extruder is 42, and the screw barrel The temperature is 180-240°C, the screw speed is 380r / min, and the pressure is 12MPa.

[0047] Surface modification of HIPS materials, the method is as follows:

[0048] The HIPS prefabricated material prepared above was injection molde...

Embodiment 3

[0053] Embodiment 3 of the present invention discloses a preparation method of a modified HIPS composite material, and the adopted technical scheme is as follows:

[0054] A preparation method of modified HIPS composite material, comprising the following steps:

[0055] Preparation of HIPS prefabricated materials, injection molding;

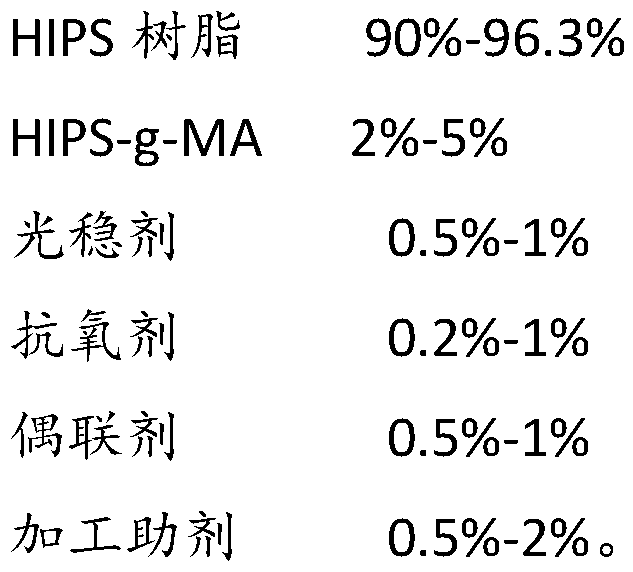

[0056] The component raw materials of the prefabricated materials are calculated by weight percentage and consist of the following raw materials:

[0057]

[0058] Mix each component in a high-speed mixer for 8 minutes; use a twin-screw extruder to melt and extrude the mixed material, and granulate. The process conditions are: the aspect ratio of the twin-screw extruder is 46, and the screw barrel The temperature is 180-240°C, the screw speed is 450r / min, and the pressure is 18MPa.

[0059] Surface modification of HIPS materials, the method is as follows:

[0060] The HIPS prefabricated material prepared above was injection molded into a samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com