Vortex self-cleaning energy-saving pipe

A vortex and spiral technology, applied in the field of condenser tubes, can solve the problems of increasing the difficulty of cleaning, complex manufacturing, and damage to the boundary layer, etc., to enhance the convective heat transfer and condensation heat release coefficient, enhance the mechanical strength and anti-vibration performance, The effect of preventing the generation of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described as follows:

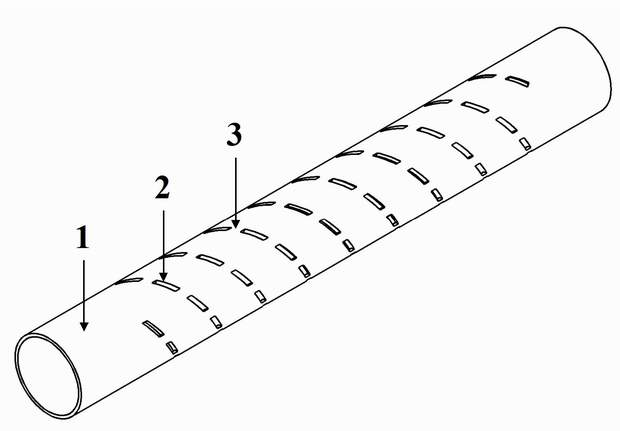

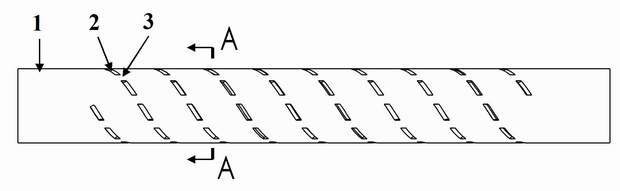

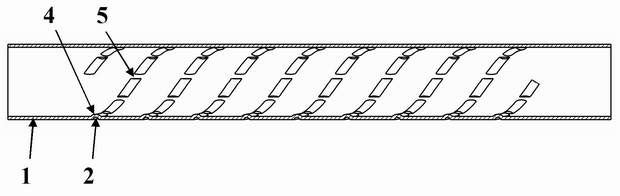

[0017] The constituent elements of the vortex cleaning tube of the present invention are: tube body 1, outer wall surface groove 2, outer wall surface groove gap 3, inner wall surface protrusion 4, inner wall surface protrusion gap 5; outer wall surface groove 2 is spiral along the outer wall of the tube The lines are distributed on the outer wall of the tube, and there is a gap 3 between the grooves; the inner wall has protrusions 4 corresponding to the grooves on the outer wall, so the protrusions 4 are distributed in a spiral shape along the inner wall of the tube, and there are gaps between the inner wall protrusions. Gap 5, see attached Figure 1-7 As shown, the number of heads of the spiral can be single head, double head, three heads, four heads, five heads, and six heads. Figure 4 Where p is the pitch between adjacent helices, the pitch p between the helices is equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com