Novel preparation method for oxidized cellulose

A technology for oxidizing cellulose and cellulose, applied in the field of preparing oxidized cellulose, can solve the problems of poor thermal conductivity of regenerated cellulose, low energy consumption and efficiency, high degradation of products, etc. The effect of increasing the coefficient and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

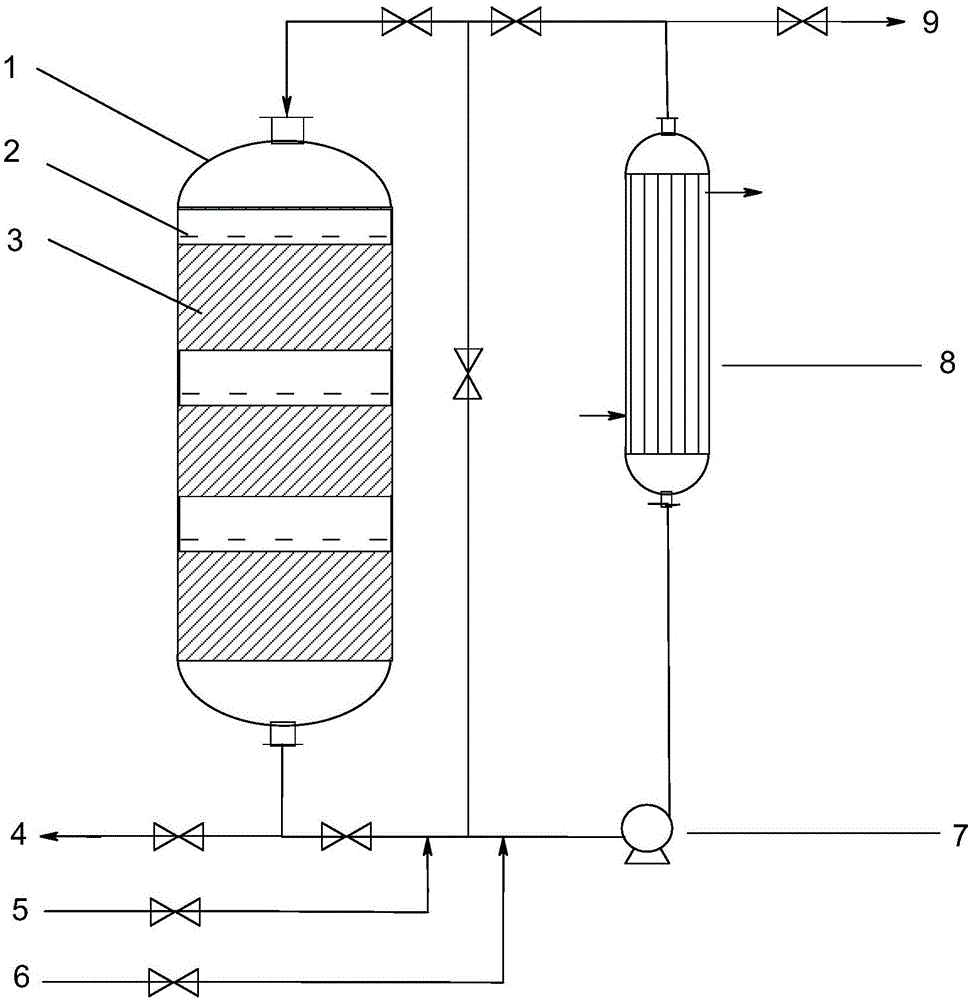

Method used

Image

Examples

Embodiment 1

[0035] 1) In the external circulation pulsating reactor, add cellulose fiber fabric (denier 150 denier) raw materials, open the external circulation pump for oxygen removal and nitrogen replacement protection; open the heat exchanger;

[0036] 2) After the replacement of deoxygenation and nitrogen filling is complete, the system is evacuated;

[0037] 3) Slowly open the nitrogen dioxide pipeline, open the nitrogen pipeline, the mixed gas is pumped in, the nitrogen dioxide volume concentration is 55%, and passes through the heat exchanger to control the air flow temperature at 0 ° C in the reactor and the cellulose The raw materials are contacted, a selective oxidation reaction occurs, and the cycle reaction is continuously carried out to promote the completion of the reaction. The pressure in the reactor is -0.090MPa. Wherein, the gas circulation switch in the external circulation oxidation reactor is closed and opened to perform gas flow pulsation at a pulsation ratio of 20s...

Embodiment 2

[0041] 1) In the external circulation pulsating reactor, add regenerated cellulose fiber fabric (denier 0.5 denier) raw materials, open the external circulation pump for oxygen removal and nitrogen replacement protection; open the heat exchanger;

[0042] 2) After the replacement of deoxygenation and nitrogen filling is complete, the system is evacuated;

[0043] 3) Slowly open the nitrogen dioxide pipeline, open the nitrogen pipeline, the mixed gas is pumped in, the nitrogen dioxide volume concentration is 1%, and passes through the heat exchanger to control the air flow temperature at 160 ° C in the reactor and the cellulose The raw materials are contacted, a selective oxidation reaction occurs, and the cycle reaction is continuously carried out to promote the completion of the reaction. The pressure in the reactor was 1.0 MPa. Wherein, the air flow circulation switch in the external circulation oxidation reactor is closed and opened to perform air flow pulsation at a pulsa...

Embodiment 3

[0047] 1) Add regenerated cellulose non-woven fabric (denier 3.0 denier) raw materials into the external circulation pulsating reactor, turn on the external circulation pump for oxygen removal and nitrogen replacement protection; turn on the heat exchanger;

[0048] 2) After the replacement of deoxygenation and nitrogen filling is complete, the system is evacuated;

[0049] 3) Slowly open the nitrogen dioxide pipeline, open the nitrogen pipeline, the mixed gas is pumped in, the nitrogen dioxide volume concentration is 2%, and passes through the heat exchanger to control the air flow temperature at 80 ° C in the reactor and the cellulose The raw materials are contacted, a selective oxidation reaction occurs, and the cycle reaction is continuously carried out to promote the completion of the reaction. The pressure in the reactor was 0.0 MPa (gauge pressure). Wherein, the gas circulation switch in the external circulation oxidation reactor is closed and opened to perform gas flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com