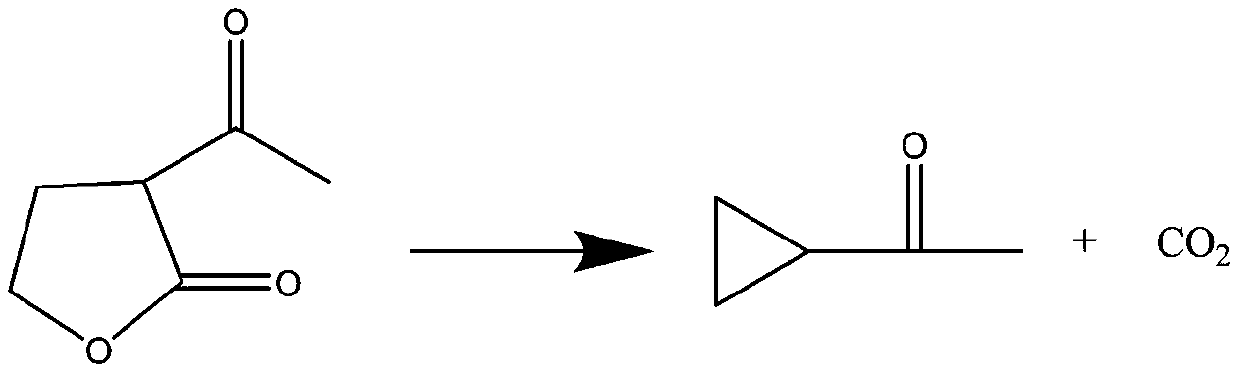

Novel catalytic cracking method of alpha-acetyl-gamma-butyrolactone

A catalytic cracking and acetylation technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of insufficient catalyst activity, multiple cracking by-products, high reaction temperature, etc. problem, achieve the effect of reducing other side reactions, high selectivity, and lowering the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

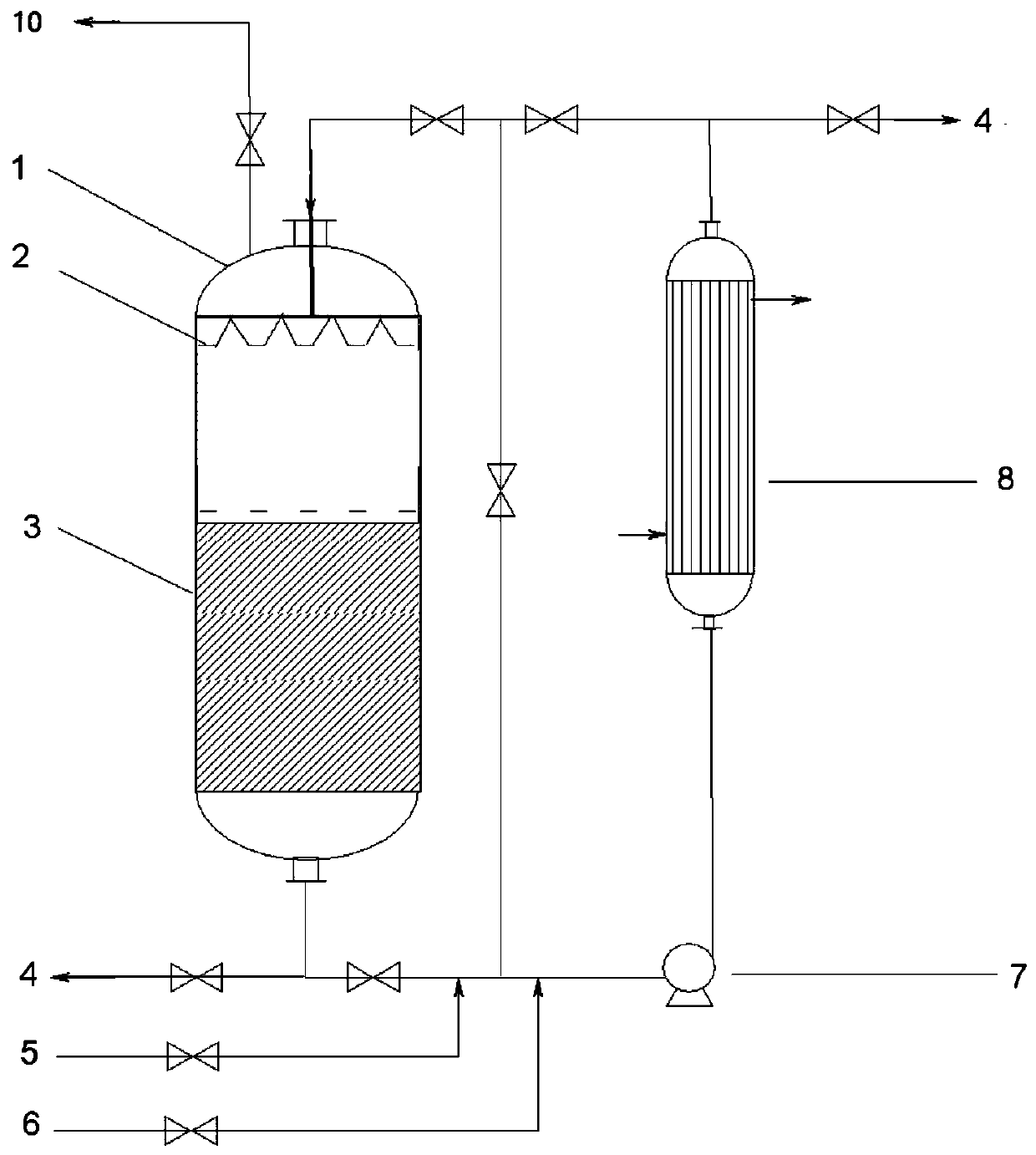

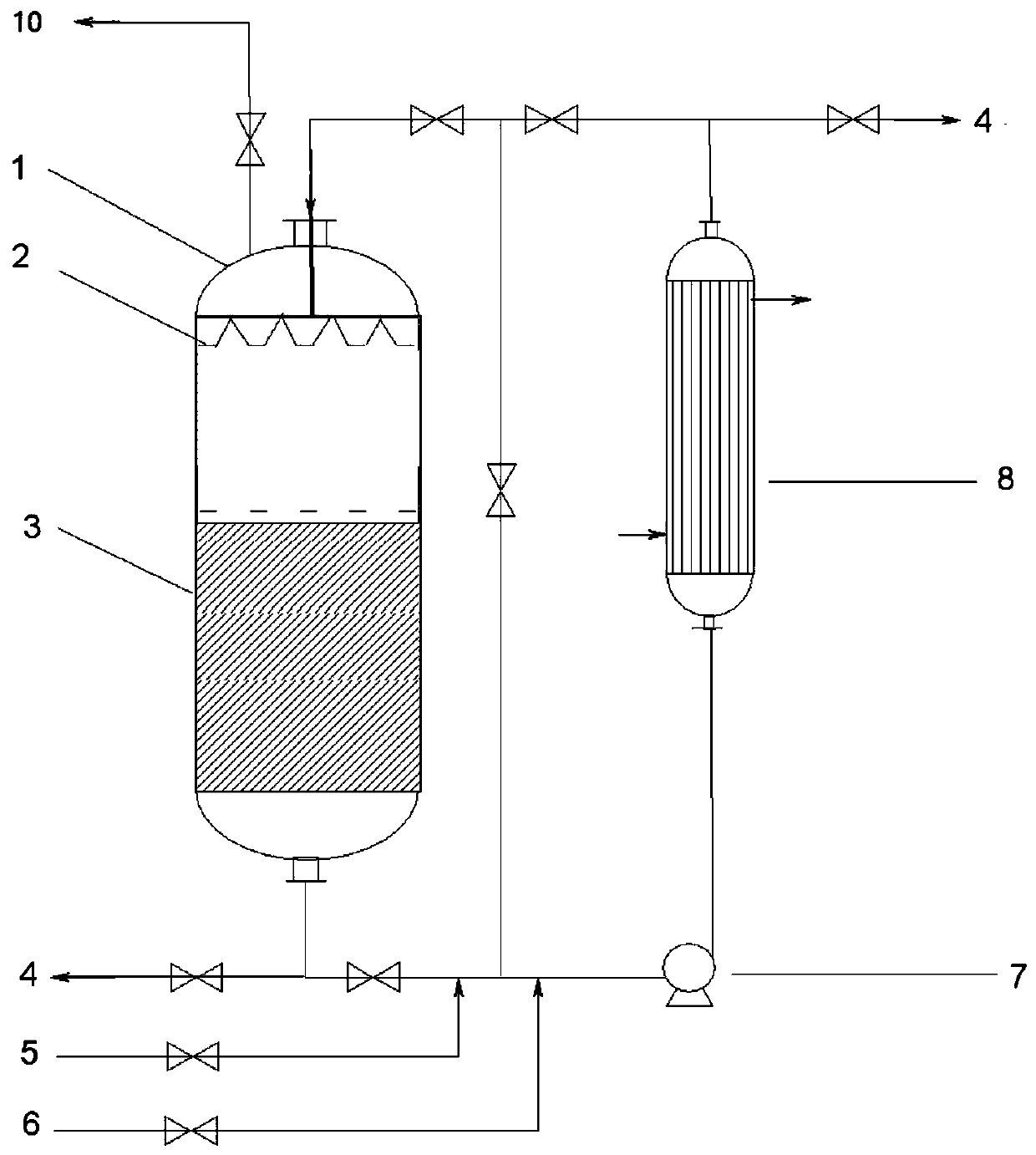

[0032] 1) In the external circulation pulse reactor 1, add α-acetyl-γ-butyrolactone 6 raw materials, add catalyst 1.0kg (sodium chloride: ZIF-67=1:0.1), the particle size of the catalyst is less than 1000 microns, And pass into dry nitrogen 5 replacement; Open heat exchanger 8;

[0033] 2) After the replacement process is completed, the system is vacuumed;

[0034] 3) Turn on the circulating pump 7, the α-acetyl-γ-butyrolactone 6 raw material is drawn in by the pump 7, and passes through the heat exchanger 8, and the temperature is controlled at 140°C to contact the catalyst in the reactor 1, and the catalyst is mixed with the raw material Liquid 3 undergoes a catalytic cracking reaction, and continuously circulates the reaction to promote the completion of the reaction. Among them, the circulation switch in the external circulation pulsation reactor 1 is closed and opened to perform fluid pulsation operation with a pulsation ratio of 20s:20s, so as to realize the pulsation t...

Embodiment 2

[0039] 1) In the external circulation pulse reactor 1, add α-acetyl-γ-butyrolactone 6 raw materials, add catalyst 1.0kg (sodium iodide: ZIF-67=1:0.5), the particle size of the catalyst is less than 500 microns, And pass into dry nitrogen 5 replacement; Open heat exchanger 8;

[0040] 2) After the replacement process is completed, the system is vacuumed;

[0041] 3) Turn on the circulation pump 7, the α-acetyl-γ-butyrolactone 6 raw material is pumped in by the pump 7, and passes through the heat exchanger 8, and the temperature is controlled at 100°C to contact the catalyst in the reactor 1, and the catalyst is mixed with the raw material Liquid 3 undergoes a catalytic cracking reaction, and continuously circulates the reaction to promote the completion of the reaction. Wherein, the circulation switch in the external circulation pulsation reactor 1 is closed and opened to perform fluid pulsation operation with a pulsation ratio of 120s:1200s, so as to realize pulsation to prom...

Embodiment 3

[0046] 1) In the external circulation pulse reactor 1, add α-acetyl-γ-butyrolactone 6 raw materials, add catalyst 1.0kg (potassium iodide: ZIF-67=1:0.2), the particle size of the catalyst is less than 500 microns, and pass Enter dry nitrogen 5 replacement; Open heat exchanger 8;

[0047] 2) After the replacement process is completed, the system is vacuumed;

[0048] 3) Turn on the circulation pump 7, the α-acetyl-γ-butyrolactone 6 raw material is pumped in by the pump 7, and passes through the heat exchanger 8, and the temperature is controlled at 130°C to contact the catalyst in the reactor 1, and the catalyst is mixed with the raw material Liquid 3 undergoes a catalytic cracking reaction, and continuously circulates the reaction to promote the completion of the reaction. Among them, the circulation switch in the external circulation pulsation reactor 1 is closed and opened to perform fluid pulsation operation with a pulsation ratio of 40s:80s, so as to realize the pulsation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com