A Method for Improving Detection Accuracy and Durability of Quartz Crystal Microbalance

A technology of quartz crystal and microbalance, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of not using quartz crystal microbalance, etc., and achieve the effect of improving accuracy, improving durability and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

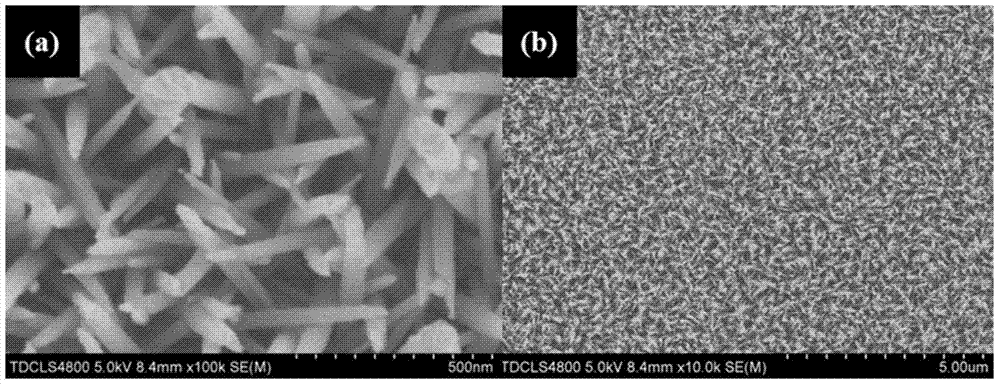

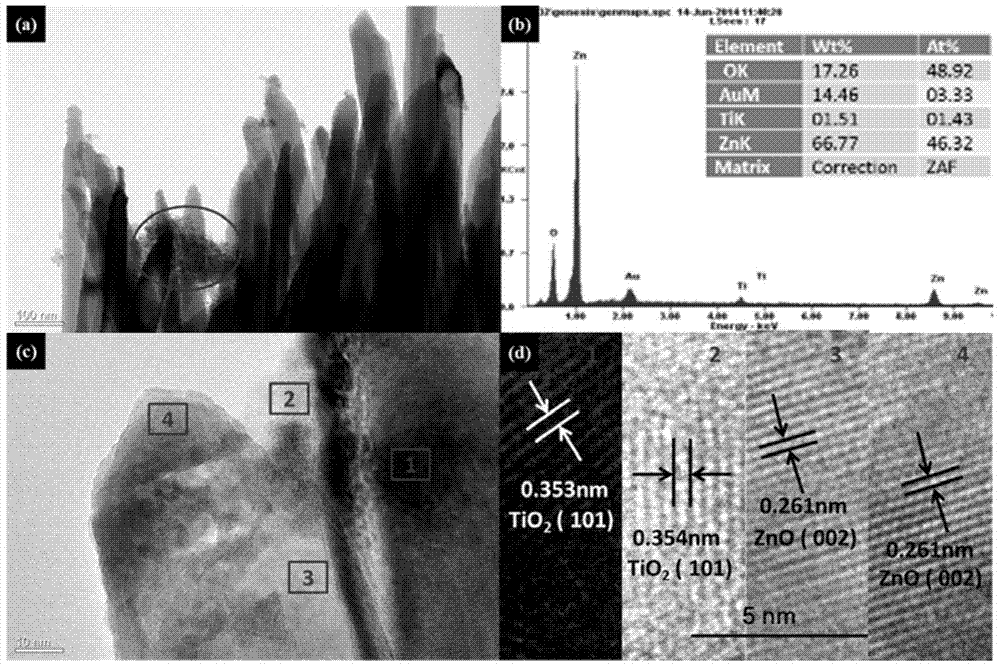

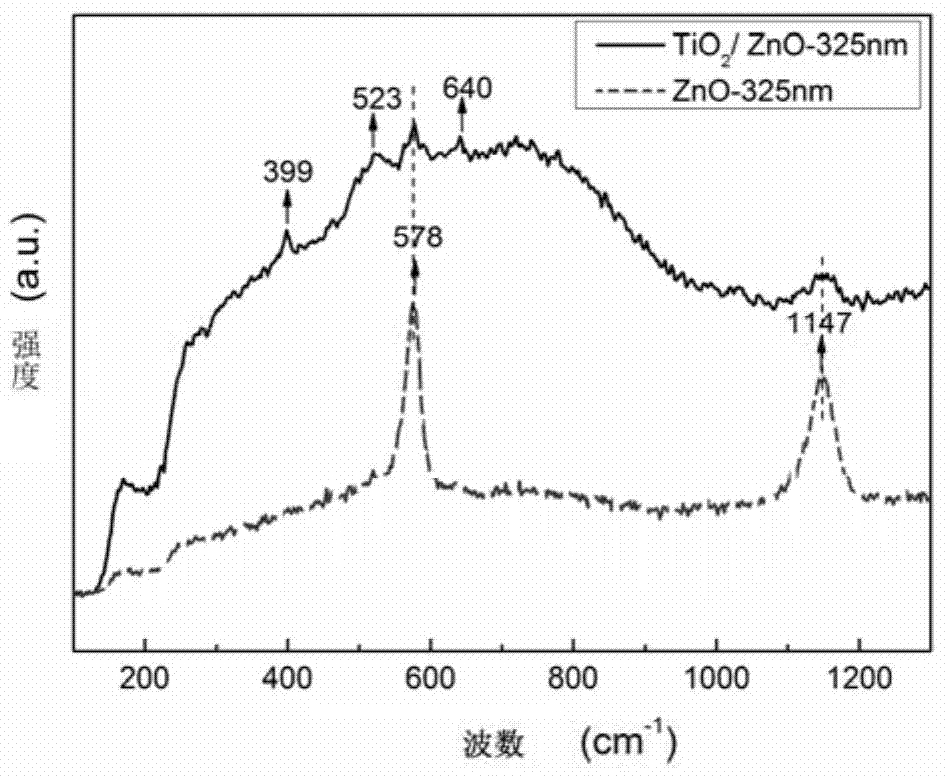

[0028] Example 1: Preparation of anatase TiO on the surface of a quartz crystal microbalance 2 / ZnO composite nanorod array as a sensitive film, including the following steps:

[0029] 1. Preparation of ZnO seed liquid:

[0030] Zinc acetate and ethanolamine were added to the ethylene glycol methyl ether solution in an equimolar ratio, and the two solutions were named A and B respectively, and were magnetically stirred at 60°C for 30 minutes, and then the B solution was slowly stirred under the action of magnetic stirring. Join in the A solution, adjust the Zn in the mixed solution by adding the amount of ethylene glycol methyl ether solution 2+ The concentration is 0.5mol / L. Then let the mixed solution continue to stir at 60°C, and add an appropriate amount of dispersant PEG after about 2 hours 400 In this way, the ZnO sol was obtained, the pH value of which was 7.39, and then the ZnO sol was statically aged at room temperature for 24 hours, which was the ZnO seed liquid f...

Embodiment 2

[0047] Example 2: Preparation of anatase TiO on the surface of a quartz crystal microbalance 2 / ZnO composite nanorod array as a sensitive film, the steps are as follows:

[0048] 1. Preparation of ZnO seed liquid: use zinc nitrate dihydrate Zn(CH 3 COO) 2 2H 2 O is used as a reaction precursor, ethanolamine (MEA) is used as a stabilizer, and ethylene glycol methyl ether is used as a solvent to prepare (Zn 2+ ) ZnO sol with a concentration of 0.3mol / L is used as the ZnO seed liquid;

[0049] 2. Form ZnO seeds on the surface of the quartz crystal oscillator by spin coating: coating time is 60s, dripping speed is 1ml / min, after coating, use infrared heating method to heat up to 300°C, heat preservation and sintering for 0.5h, stop heating, and cool naturally . A substrate with ZnO seed crystals is obtained on the surface of the quartz crystal oscillator.

[0050] 3. Grow nano-rod-shaped ZnO gas-sensing film layer by hydrothermal method: prepare zinc nitrate solution and he...

Embodiment 3

[0054] Example 3: Preparation of anatase TiO on the surface of a quartz crystal microbalance 2 / ZnO composite nanorod array as a sensitive film, the steps are as follows:

[0055] 1. Preparation of ZnO seed liquid: use zinc nitrate dihydrate Zn(CH 3 COO) 2 2H 2 O is used as a reaction precursor, ethanolamine (MEA) is used as a stabilizer, and ethylene glycol methyl ether is used as a solvent to prepare (Zn 2+ ) ZnO sol with a concentration of 0.3mol / L is used as the ZnO seed liquid;

[0056] 2. Form ZnO crystal seeds on the surface of the quartz crystal oscillator by spin coating: the coating time is 120s, and the dripping speed is 0.5ml / min. After coating, the temperature is raised to 200°C by infrared heating method, and then heat preservation and sintering for 1h, stop heating, and cool naturally . A substrate with ZnO seed crystals is obtained on the surface of the quartz crystal oscillator.

[0057] 3. Grow nanorod-shaped ZnO gas-sensitive film layer by hydrothermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com