Independent-grouting-opening-free reinforcing steel bar grouting connecting sleeve, system and construction method

A technology of grouting connection and grouting port, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve problems such as low construction efficiency, cost of grout leakage, and inconvenient construction, so as to reduce connection costs and improve construction efficiency , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

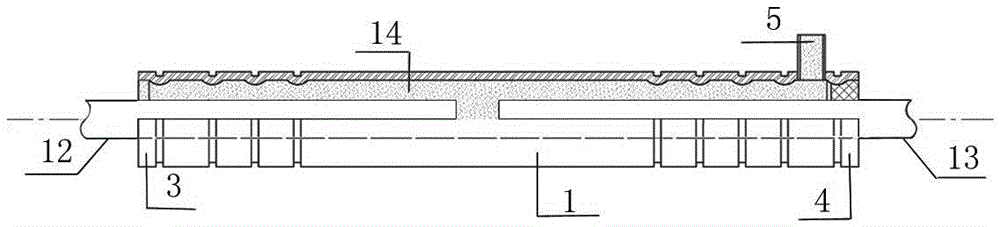

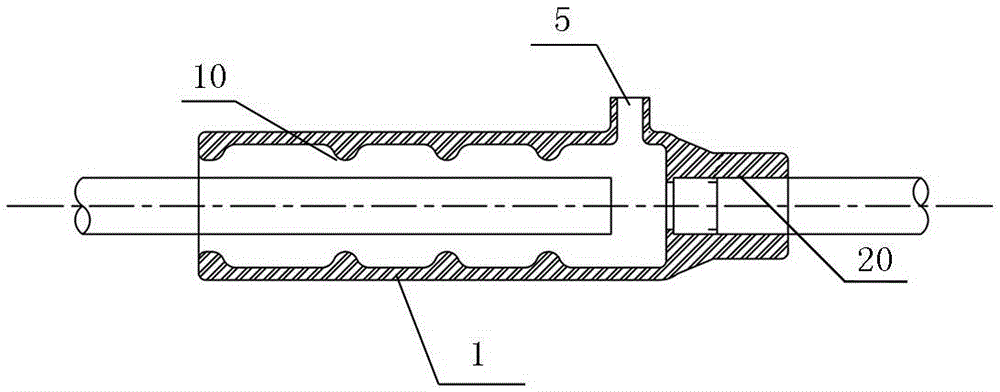

[0046] For an embodiment one of the steel bar grouting connection sleeve without an independent grouting port, see figure 1 , this kind of steel bar grouting connection sleeve without independent grouting port includes a sleeve main body 1, and the inner wall of the sleeve main body 1 is provided with a protrusion 10, and the side wall of the sleeve main body 1 is only provided with a grouting The port A5 has no grouting port, and the grouting port A5 is a rigid short pipe welded to the sleeve main body 1 . The outer wall of the sleeve body 1 is provided with a groove 11 , and the groove 11 on the outer wall of the sleeve body corresponds to the protrusion 10 on the inner wall of the sleeve body 1 . The sleeve main body 1 is formed by rolling and pressing steel pipes. The material of the sleeve body 1 is steel or iron.

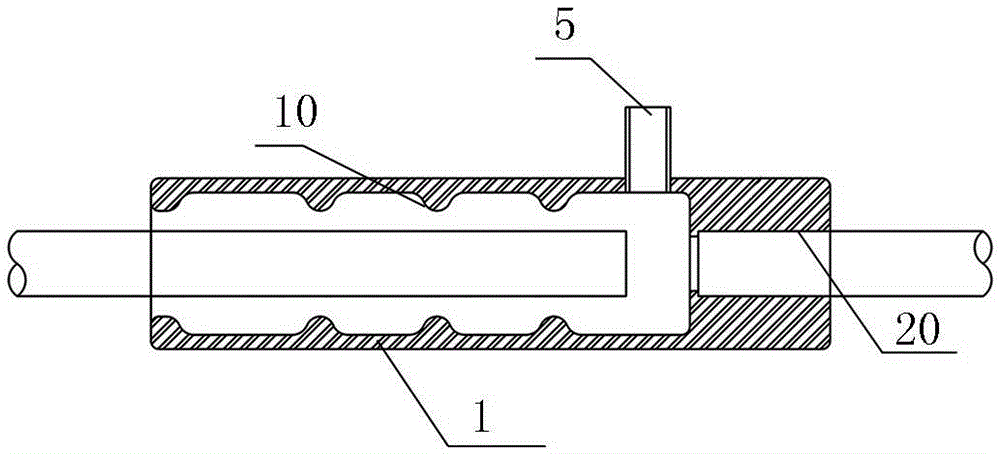

[0047] The second embodiment of the steel bar grouting connection sleeve without independent grouting port figure 2 , The difference from Embodiment 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com