Waterborne alkyd paint and preparation method thereof

A technology of water-based alkyd and water-based alkyd resin, applied in the field of paint, can solve the problems of unreasonable selection and matching of raw materials, high cost of alkyd paint preparation, complicated paint preparation process, etc., and achieve easy operation, excellent anti-rust ability, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

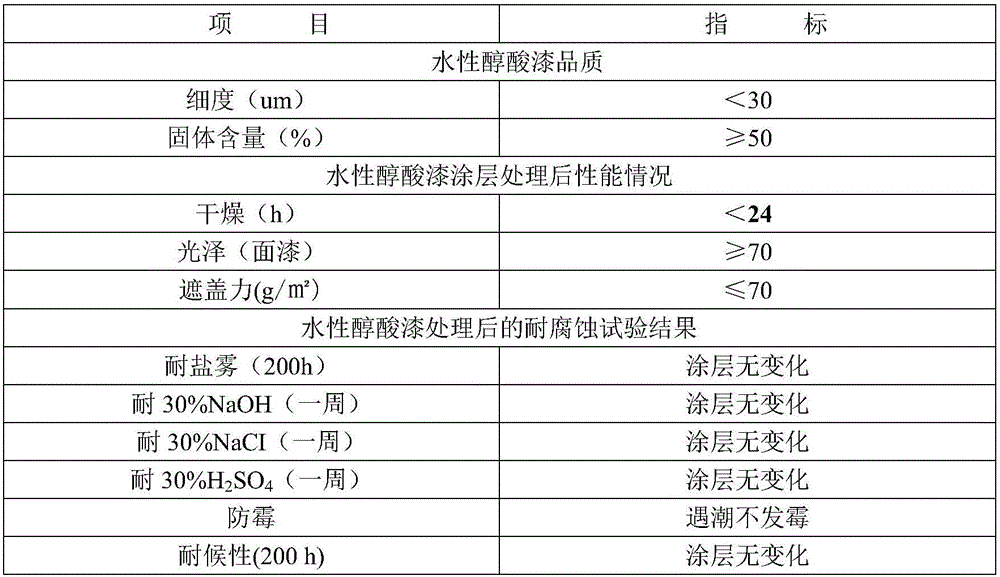

[0025] A water-based alkyd paint, the raw material components, in kg, are water-based alkyd resin 30, titanium dioxide 10, barium sulfate 9, iron-titanium powder 9, water-based dispersant 1, defoamer 0.8, rust inhibitor 0.1, thickener Agent 0.1, water 10. The water-based alkyd paint has a fineness of less than 30 microns, a solid mass content of more than 50%, a hiding power of less than 70g / ㎡, and a coating drying time of less than 24 hours. The water-based alkyd resin is DOA116. The water-based dispersant is 760W. Described defoamer is mineral oil defoamer. The mineral oil defoamer is EASYTECH DF-677. Described anti-rust agent is FA-179 anti-flash rust agent. Described thickener is WT105A thickener.

[0026] The preparation method comprises distributing the raw material components into the stirring and mixing pool, stirring at room temperature for 25 minutes, and then putting them in a grinder to grind until the fineness is less than 30 microns.

Embodiment 2

[0028] A water-based alkyd paint, raw material components, in kg, water-based alkyd resin 60, titanium dioxide 30, barium sulfate 11, iron-titanium powder 11, water-based dispersant 5, defoamer 2, rust inhibitor 0.3, thickener Agent 0.5, water 15. The water-based alkyd paint has a fineness of less than 30 microns, a solid mass content of more than 50%, a hiding power of less than 70g / ㎡, and a coating drying time of less than 24 hours. The water-based alkyd resin is DOA116. The water-based dispersant is 760W. Described defoamer is mineral oil defoamer. The mineral oil defoamer is EASYTECH DF-159. Described anti-rust agent is FA-179 anti-flash rust agent. Described thickener is WT105A thickener.

[0029] The preparation method comprises distributing the raw material components into a stirring mixing tank, stirring at room temperature for 35 minutes, and then putting them in a grinder to grind until the fineness is less than 30 microns.

Embodiment 3

[0031] A water-based alkyd paint, raw material components, in kg, are water-based alkyd resin 40, titanium dioxide 20, barium sulfate 10, iron-titanium powder 10, water-based dispersant 3, defoamer 1.4, rust inhibitor 0.2, thickener Agent 0.3, water 13. The water-based alkyd paint has a fineness of less than 30 microns, a solid mass content of more than 50%, a hiding power of less than 70g / ㎡, and a coating drying time of less than 24 hours. The water-based alkyd resin is DOA116. The water-based dispersant is 760W. Described defoamer is mineral oil defoamer. The mineral oil defoamer is Rhodoline DF 681F, Rhodoline DF691 and Rhodoline DF 581B mixed in any mass ratio. Described anti-rust agent is FA-179 anti-flash rust agent. Described thickener is WT105A thickener.

[0032] The preparation method comprises distributing the raw material components into the stirring and mixing pool, stirring at room temperature for 30 minutes, and then placing them in a grinder to grind to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com