Construction method for rapid escape of cutter head in permafrost at the initial stage of shield tunneling

A construction method and cutter head technology, which is applied to earthwork drilling, mining equipment, tunnels, etc., can solve the problems of long time consumption, low success rate, and high risk of equipment damage, and achieve the effect of strong process pertinence and reasonable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The invention provides a construction method for quick escape of a cutterhead in the initial stage of shield tunneling, and is especially suitable for quick escape of a cutterhead in frozen soil. In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

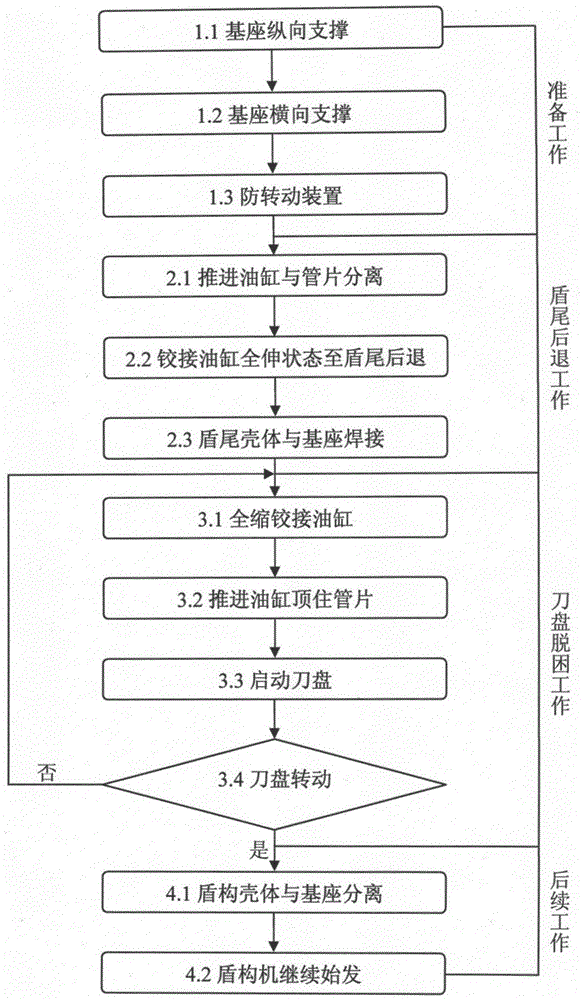

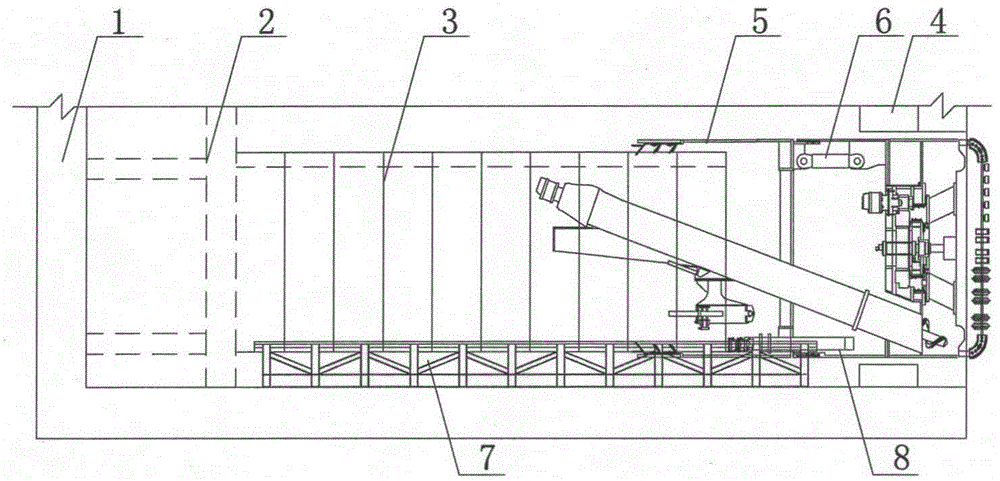

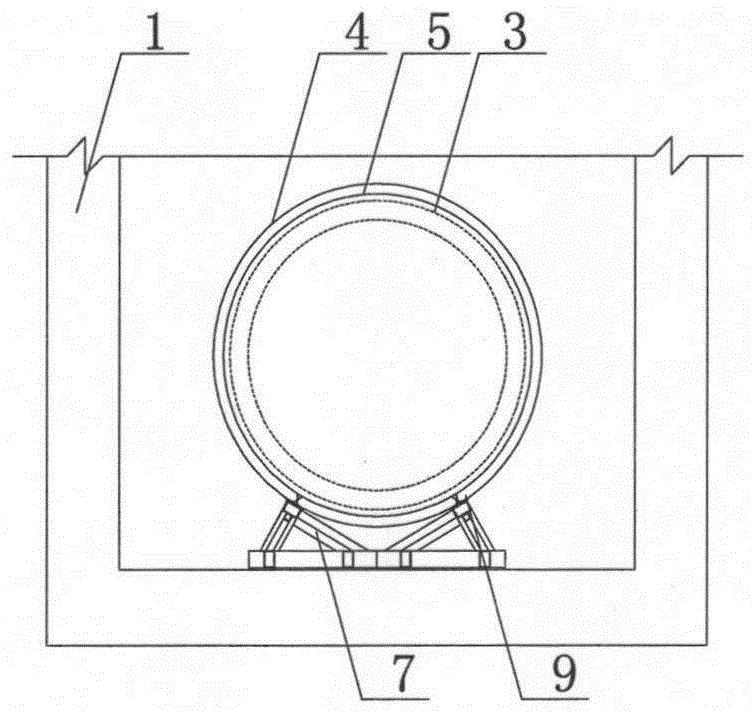

[0046] figure 1 It is a construction flowchart of the present invention, including four steps of preparatory work, shield tail retreating work, cutterhead escape work, and follow-up work. Among them, the preparatory work includes the following processes: longitudinal support of the base, horizontal support of the base, and anti-rotation device; the process of retreating the shield tail includes: separating the propulsion cylinder from the segment, fully extending the hinged cylinder until the shield tail retreats, The tail shell is welded to the base; the cutterhead release work includes the following processes: fully retract the hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com