Catalytic cracking method and device in favor of processing inferior heavy oil

A low-quality heavy oil, catalytic cracking technology, applied in the petroleum industry, processing hydrocarbon oil, etc., can solve the problems of large deviation of raw material oil quality, high coke generation rate of low-quality oil, catalyst regeneration, etc., to achieve improved energy consumption, good production environment, Effect of improving yield and added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

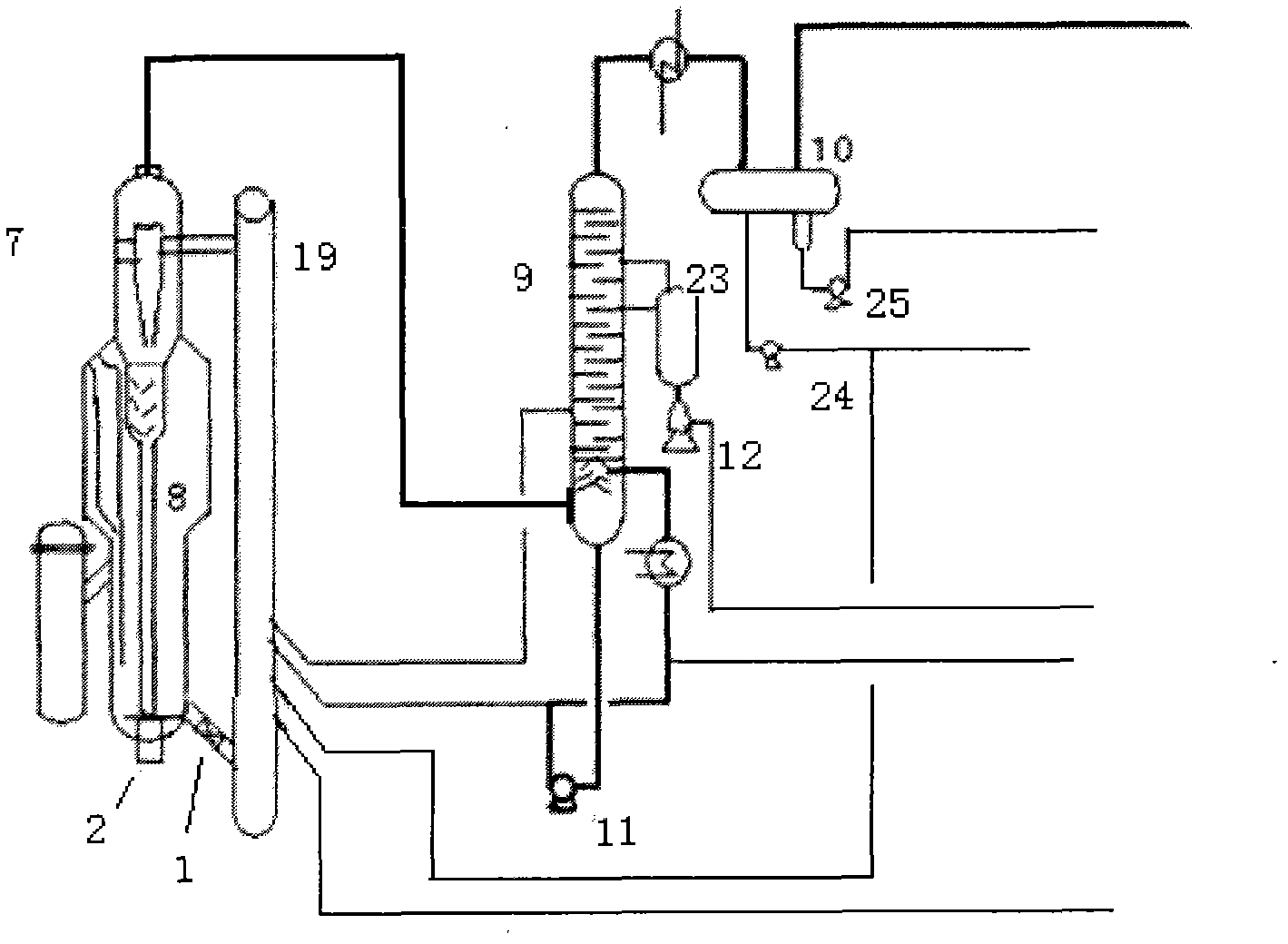

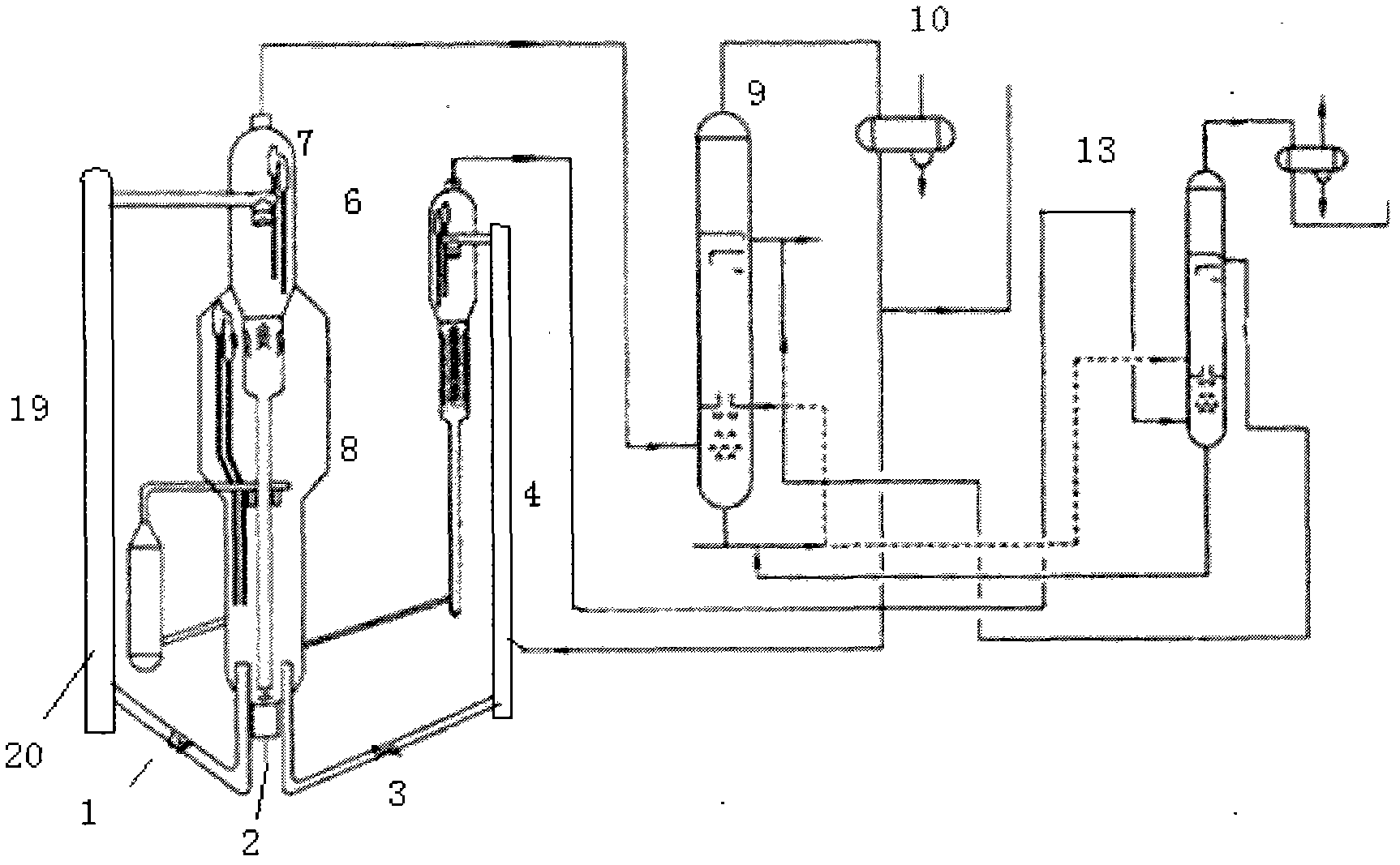

[0022] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

[0023] The technological process of the catalytic cracking method described in this embodiment, which is beneficial to the processing of inferior heavy oil, includes a main reaction part, a side reaction part and a regeneration system part.

[0024] Such as figure 1 As shown: the main reaction process is to fully mix the crude oil with a density ≤ 0.935 and a carbon residue value ≤ 8 into the ordinary heavy oil riser 19 through the feed oil nozzle 20 of the ordinary heavy oil riser, and fully mix it with the regenerated catalyst that enters through the regeneration slide valve 1 of the ordinary heavy oil riser Carry out the cracking reaction to form oil and gas enter the heavy oil settler 7, and separate the catalyst in the oil and gas through the heavy oil settler cyclone separator of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com