Method for preparing proppant

A technology of proppant and walnut shell, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well parts, etc., can solve the problems of high cost, high price, serious environmental pollution, etc., and achieve good compressibility and toughness, and make The effect of low cost and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

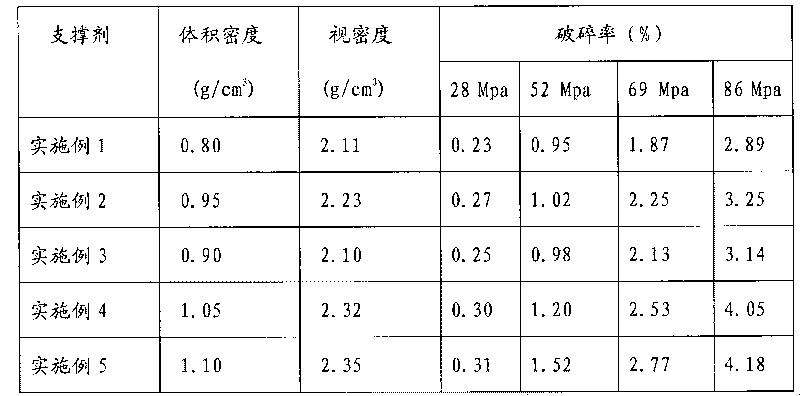

Embodiment 1

[0017] Take 3 kg of crushed and granulated walnut shell particles of 20-40 mesh, add 6 kg of 1% sodium hydroxide solution, heat at 60°C for 3 hours, filter, wash with water, and dry at 45°C After 8 hours, the modified walnut shell was obtained. The modified walnut shell is heated and mixed with 0.03 kg of phenolic resin and 0.06 kg of hexamethylenetetramine, so that the phenolic resin is coated on the surface of the walnut shell particles, and the above solid mixture is cooled, crushed and sieved to obtain Finished proppant. Its properties are shown in Table 1.

[0018] In this embodiment, hexamethylenetetramine is the curing agent, and the following embodiments are the same.

Embodiment 2

[0020] Take 3 kg of crushed and granulated 20-40 mesh walnut shell particles, add it to 30 kg of 5% sodium hydroxide solution, heat at 40°C for 5 hours, filter, wash with water, and dry at 30°C After 10 hours, the modified walnut shell was obtained. The modified walnut shell is heated and mixed with 0.12 kg of phenolic resin and 0.006 kg of hexamethylenetetramine, so that the phenolic resin is coated on the surface of the walnut shell particles, and the above solid mixture is crushed and sieved to obtain the finished support agent. Its properties are shown in Table 1.

Embodiment 3

[0022] Take 3 kg of crushed and granulated 20-40 mesh walnut shell particles, add 15 kg of 3% potassium hydroxide solution, heat at 50°C for 3 hours, filter, wash with water, and dry at 30°C After 10 hours, the modified walnut shell was obtained. The modified walnut shell is heated, mixed and stirred with 0.06 kg of phenolic resin and 0.006 kg of hexamethylenetetramine, so that the phenolic resin is coated on the surface of the walnut shell particles, and the above solid mixture is cooled, crushed and sieved That is, the finished proppant is obtained. Its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com