Silicon glass spacing plate for accumulator as well as preparing technique thereof

A manufacturing process and storage battery technology, applied to battery components, circuits, electrical components, etc., can solve the problems of increased battery manufacturing cost, low apparent density, small specific surface area, etc., and achieve increased cycle life and crush resistance Big, tech-heavy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

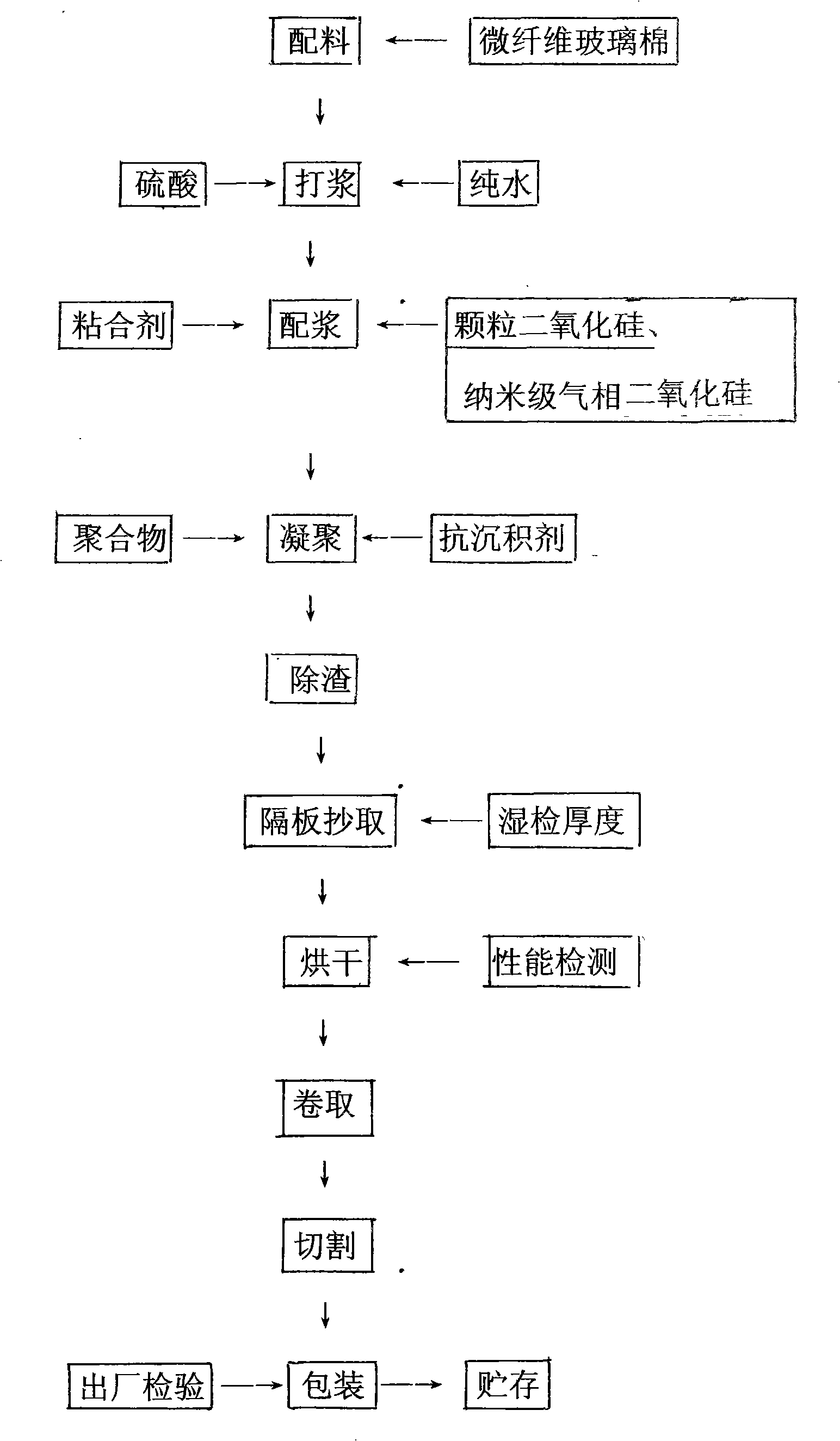

[0025] As shown in the figure, the manufacturing process flow of the present invention is:

[0026] Raw material (microfiber glass wool) - beating (adding pure water and sulfuric acid) - mixing (adding granular silica, nano-scale fumed silica mixture and binder) - agglomeration (adding polymer and anti- Sedimentation agent) - slag removal - clapboard copying - drying - coiling - cutting - packaging.

[0027] Concrete manufacturing process of the present invention is:

[0028] 1. Selection of raw materials - first select microfiber glass wool, granular silica and nano-scale fumed silica and binder mixture, polymer, and anti-deposition agent according to the formula ratio.

[0029] 2. Beating - Put the microfiber glass wool into the mixing tank, add pure water and sulfuric acid to stir and beat.

[0030] 3. Slurry preparation—add the uniformly stirred microfiber glass wool into the mixture of granular silica, nano-scale fumed silica and binder in the stirring tank, and stir ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com