Compressive skin-foam-skin insulated single wire and preparation method thereof

A bubble-skin and single-wire technology, applied in the direction of insulating cables, insulating conductors, conductors/cables, etc., can solve problems such as weak flattening resistance, potential safety hazards, buried product quality, etc., and achieve material cost savings and safe use The effect of guaranteeing and improving the anti-crush performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

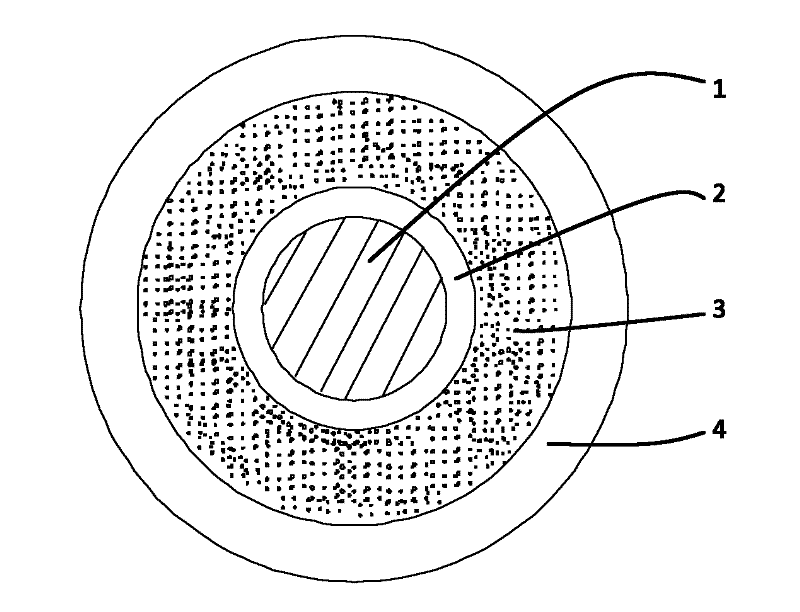

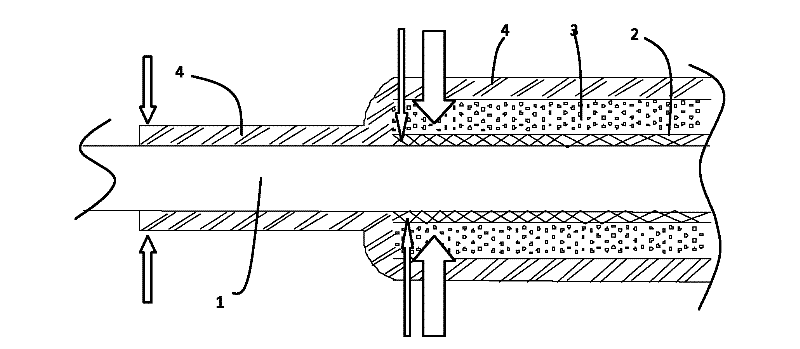

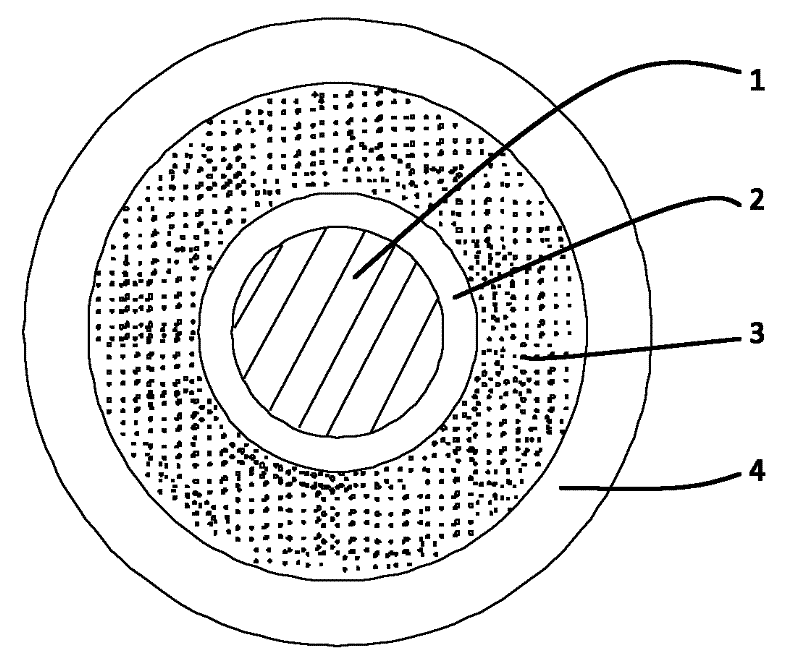

[0025] The following will be combined with figure 1 The present invention is further described. But the content of the present invention is not limited thereto.

[0026] see figure 1 , according to the present invention, a kind of pressure-resistant type leather-foam-skin insulated single wire, which includes a copper conductor 1, an inner skin layer 2 wrapped outside the copper conductor 1, a central foam layer 3 wrapped outside the inner skin layer 2, and a coating The outer skin layer 4 on the central foam layer 3 .

[0027] The copper conductor 1 is a TR type soft round copper wire with a diameter of 1.0 mm.

[0028] The inner skin layer 2 uses a low-density polyolefin material to bond the copper conductor 1 and the central foam layer 3 together. Due to the high viscosity of the low-density polyolefin material, it can better adhere to the copper conductor 1 and the central foam layer 3 during the extrusion process, and play the role of a double-sided adhesive.

[0029...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com