Composite sintered compact

A sintered body, volume technology, used in the manufacture of tools, transportation and packaging, accessories for tool holders, etc., can solve problems such as binder falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

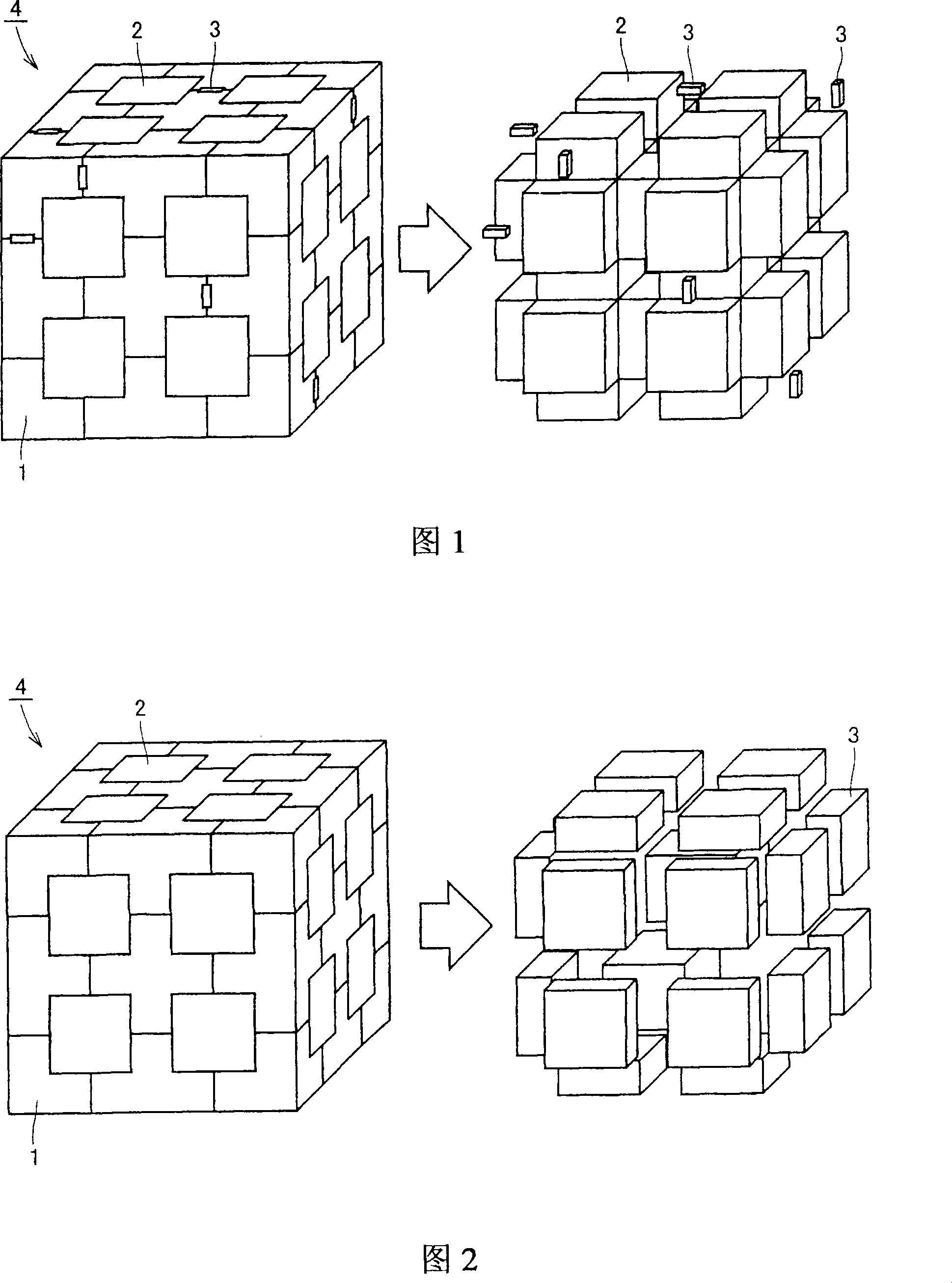

Method used

Image

Examples

Embodiment 1

[0095] First, the Ti X N Y (wherein X=0.5 and Y=0.25) powder and Al powder were uniformly mixed together at a mass ratio of 80:20, and then the resulting mixed powder was vacuum heat-treated at a temperature of 1200° C. for 30 minutes using a vacuum furnace. Thereafter, the mixed powder subjected to the above heat treatment was pulverized using a ball mill composed of a barrel (made of cemented carbide) and balls (made of cemented carbide), thereby obtaining a binder raw material powder.

[0096] Next, the cubic boron nitride powder with an average particle diameter of 3.8 μm and the binder raw material powder obtained in the above manner were uniformly mixed with a ball mill so that the cubic boron nitride powder accounted for 70% by volume. Thereafter, the obtained mixed powder was placed in a vacuum furnace at a temperature of 900° C. for 20 minutes for degassing treatment.

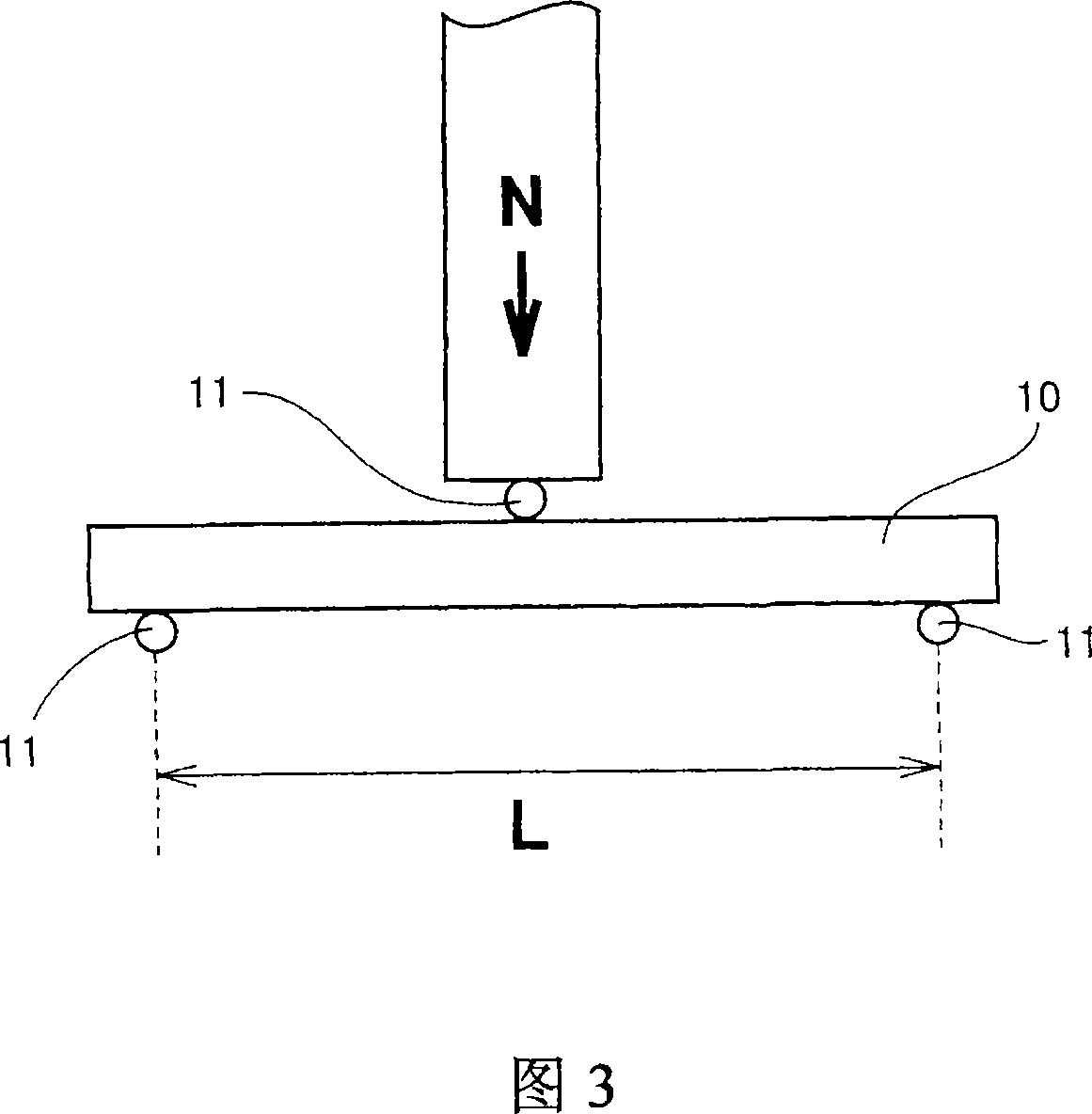

[0097] Then, the mixed powder subjected to the above-mentioned degassing treatment was sandwiched...

Embodiment 2 to 3

[0110] Prepare the composite sintered body of the present invention according to the method in Example 1, the difference is that Zr X N Y (where X=0.5 and Y=0.25) powder (Example 2) or Ti X C Y N Z (where X=0.5 and Y=Z=0.125) powder (Example 3) instead of Ti in Example 1 X N Y (where X=0.5 and Y=0.25) powder. Table 1 below shows various properties measured or tested according to the method in Example 1.

Embodiment 4 to 5

[0112] Prepare the composite sintered body of the present invention according to the method in embodiment 1, difference is: the mixing ratio of cubic boron nitride powder is changed from 70 volume % in embodiment 1 to 75 volume % (embodiment 4) or 65 Volume % (Example 5). Table 1 below shows various properties measured or tested according to the method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com