Charging gun

A charging gun and charging head technology, applied in the field of charging guns, can solve the problems of inability to open and close the electrical path of the charging gun, poor waterproof performance of the casing, low overall strength, etc., and achieve good rolling resistance and improve waterproofness. performance, the effect of ensuring the charging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

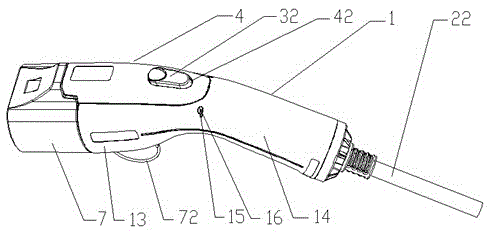

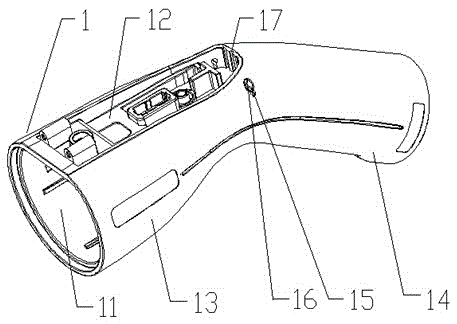

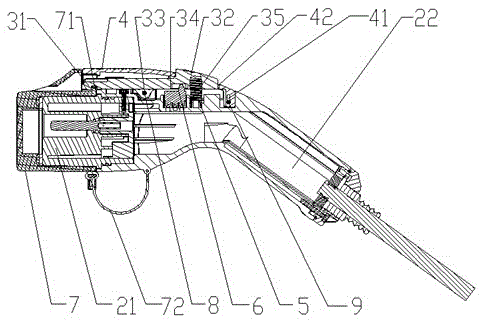

[0024] The invention discloses a charging gun suitable for use in the charging process of an electric vehicle or a hybrid vehicle.

[0025] As shown in the figure, a charging gun includes a gun body shell 1, the gun body shell 1 is an integrally formed smooth transition structure, and the integrally formed smooth transition structure includes a complete inner cavity 11, as described here The complete inner cavity 11 means that the inner cavity 11 is an integrated structure, and is not formed by splicing a plurality of outer casings. Such a setting can greatly improve the waterproof performance and anti-rolling performance of the charging gun, and has a good use effect.

[0026] The inner cavity 11 is fixed with a charging assembly 2, the charging assembly 2 includes a charging head 21 and a charging cable 22, and an assembly cavity 12 for parts assembly is arranged above the inner cavity 11, and a locking plate 3 and the gun body upper cover 4 are all connected with the gun b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com