Method for preparing polyvinylidene fluoride hollow fiber alloy film

A polyvinylidene fluoride and polyvinylidene fluoride resin technology, which is applied in the field of preparing polyvinylidene fluoride hollow fiber alloy membranes, can solve the problems of dissolution loss, rising inlet pressure, and decreasing hydrophilicity, and achieves stable chemical properties and improved The effect of crush resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Dimethylacetamide (Korea Samsung, industrial first-grade pure, the same below) 63wt%, polyvinylidene fluoride resin (Solef 6010, the same below) 18wt%, chlorinated polyvinyl chloride resin (chlorine content 68%) 3wt%, polyethylene glycol 5wt%, propylene glycol 11wt%, stirred and dissolved uniformly at 60°C, and defoamed. The conventional solution phase transfer method in the prior art is used for spinning, the coagulant in the coagulation bath is water, the spinning core liquid is a 50wt% dimethylacetamide aqueous solution, and the spinning traction speed is 50m / min. An externally pressured polyvinylidene fluoride hollow fiber porous membrane with an inner diameter of 0.60 mm, a wall thickness of 0.20 mm, a burst pressure of 0.42 MPa, and an externally compressed flattening pressure of 0.30 MPa was obtained. After being thoroughly cleaned with absolute ethanol and dried, the contact angle of the outer surface of the hollow fiber membrane is 67 0 . Pure water init...

Embodiment 2

[0031] Example 2: Dimethylacetamide 63wt%, polyvinylidene fluoride resin 19wt%, chlorinated polyvinyl chloride resin 2wt%, polyvinylpyrrolidone (K-30) 5wt%, propylene glycol 11wt%, stirred at 60°C Dissolve uniformly and defoam. The conventional solution phase transfer method in the prior art is used for spinning, the coagulant in the coagulation bath is water, the spinning core liquid is a 50wt% dimethylacetamide aqueous solution, and the spinning traction speed is 50m / min. An externally pressured polyvinylidene fluoride hollow fiber porous membrane with an inner diameter of 0.6 mm, a wall thickness of 0.20 mm, a burst pressure of 0.41 MPa, and an externally compressed flattening pressure of 0.28 MPa was obtained. After fully washing with absolute ethanol and drying, the contact angle of the outer surface of the hollow fiber membrane is 66 0 . Pure water initial permeation flux 970L / m 2 ·H@0.1MPa20℃, membrane separation pore size is 0.10μm.

Embodiment 3

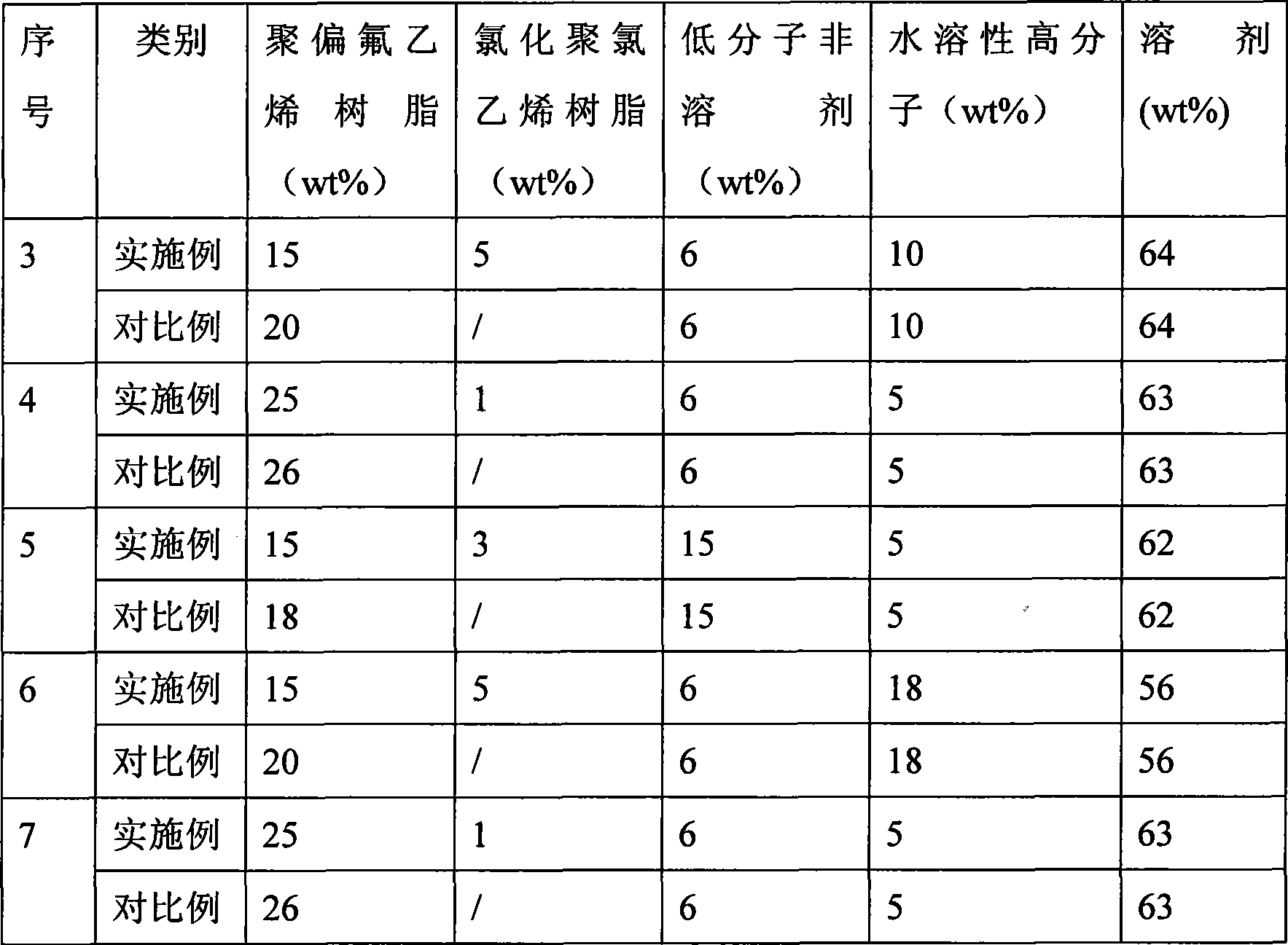

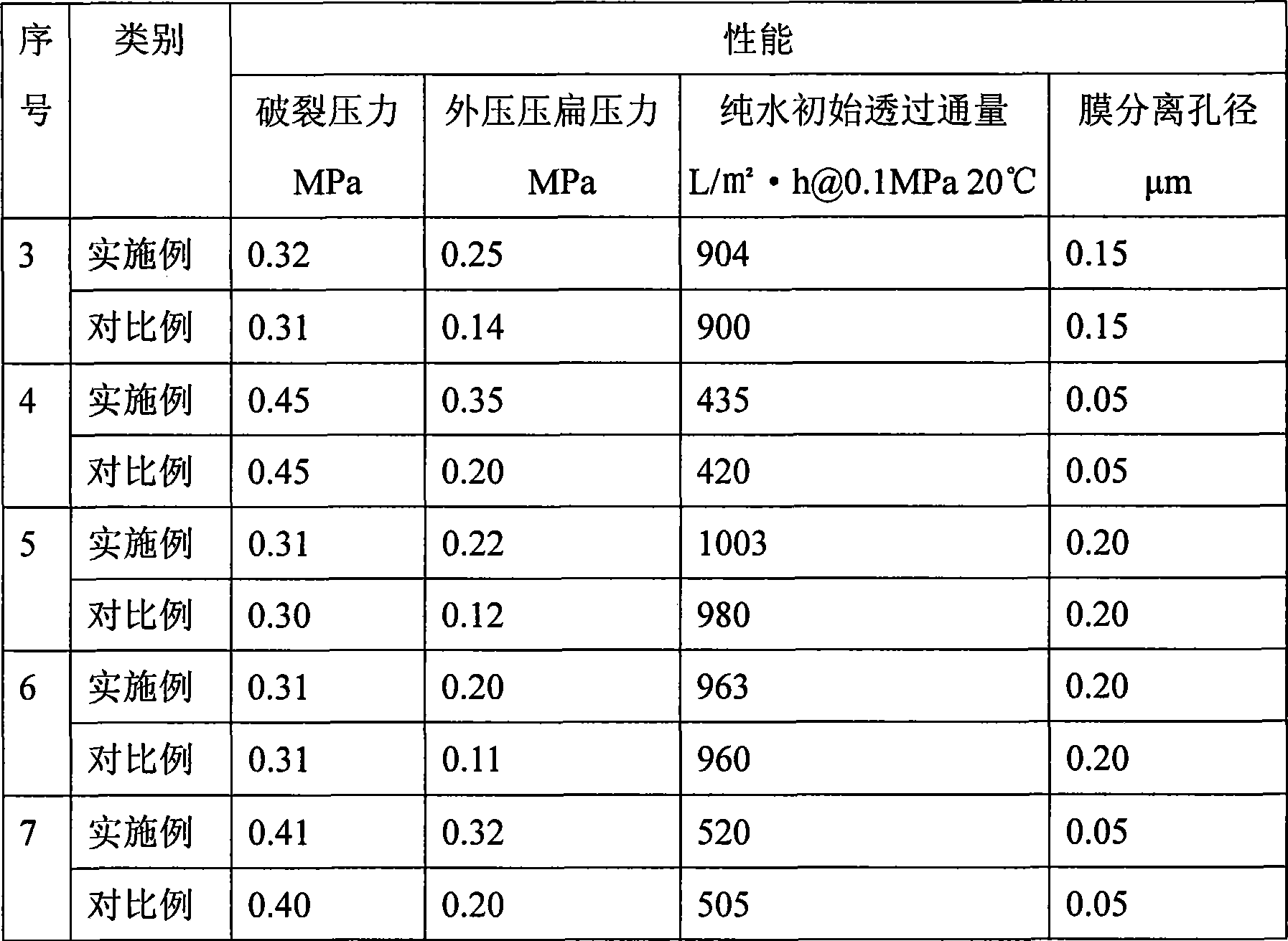

[0033] The solvent used in Example 3 and Comparative Example 3 was dimethylformamide (DMF), the low-molecular non-solvent used was ethylene glycol, and the water-soluble polymer used was polyethylene glycol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Burst pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com