Catalyst for alkyl aromatics dehydrogenation

A technology for alkyl aromatic hydrocarbons and catalysts, which is applied in the field of catalysts for ethylbenzene dehydrogenation to styrene, can solve the problems of reduced crush resistance of catalyst particles, low catalytic activity and high potassium content, and achieves high crush resistance, high The effect of low styrene yield and preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

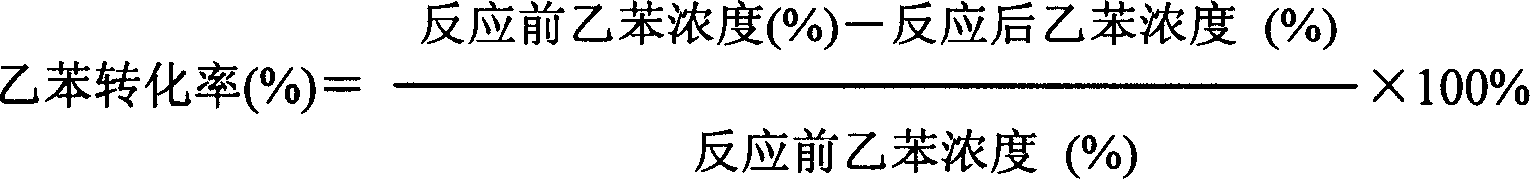

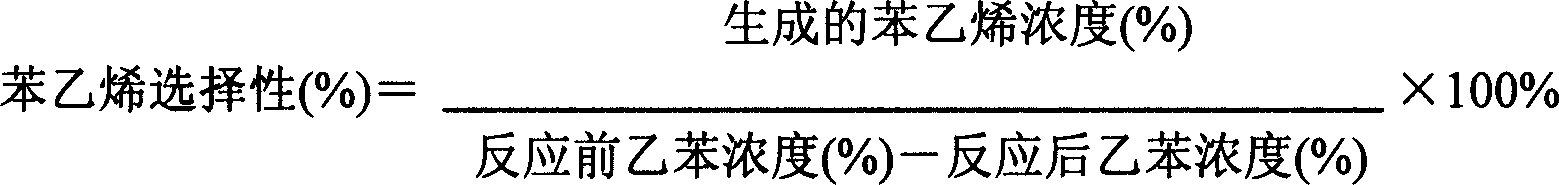

Embodiment 1

[0024] Mix 300 grams of red iron oxide, 53 grams of potassium carbonate, 35 grams of cerium oxide, 15 grams of lithium carbonate, 11 grams of magnesium oxide, 5 grams of aluminum oxide, 12 grams of cement, and 8 grams of carboxymethyl cellulose, and add an appropriate amount of deionized Water, wet ingredients kneaded to a dough-like material suitable for extruding. Extrude and cut into pellets with a diameter of 3 mm and a length of about 5 mm. Aged at room temperature for 8 hours, placed in an oven, dried at 80°C for 4 hours, placed in a calcination furnace, and calcined at 800°C for 2 hours to obtain a finished catalyst. 100 ml of catalyst was loaded into the evaluation reactor, and the catalytic activity was evaluated at a reaction temperature of 610°C and a water ratio of 2.0, and the crush resistance and wear rate of the catalyst were measured. Test results: the conversion rate of ethylbenzene is 75.1%, the selectivity of styrene is 94.3%, the yield of styrene is 70.8%,...

Embodiment 2

[0026] Mix 210 grams of iron oxide red, 120 grams of iron oxide yellow, 56 grams of potassium carbonate, 35 grams of cerium oxide, 15 grams of lithium carbonate, 6 grams of tungsten oxide, 11 grams of magnesium oxide, 20 grams of cement, and 8 grams of carboxymethyl cellulose Evenly, add an appropriate amount of deionized water, prepare and measure according to the method of Example 1. Test results: Ethylbenzene conversion rate 74.5%, styrene selectivity 95.1%, styrene yield 70.8%, crush resistance 100 Newton, wear rate 1%.

Embodiment 3

[0028] 210 grams of iron oxide red, 120 grams of iron oxide yellow, 61 grams of potassium carbonate, 35 grams of cerium oxide, 15 grams of lithium carbonate, 6 grams of tungsten oxide, 11 grams of magnesium oxide, 2 grams of molybdenum oxide, 4 grams of copper oxide, 2 grams Lead oxide, 2 grams of tin oxide, 20 grams of cement, and 8 grams of carboxymethyl cellulose were mixed evenly, and an appropriate amount of deionized water was added, prepared and measured according to the method in Example 1. Test results: Ethylbenzene conversion rate 75.1%, styrene selectivity 95.2%, styrene yield 71.5%, crush resistance 121 Newton, wear rate 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| crushing resistance | aaaaa | aaaaa |

| crushing resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com