Nano-imprint template and preparation method thereof

A nano-imprinting and template technology, applied in optical mechanical equipment, photo-engraving process of pattern surface, optics, etc., can solve the problems of poor crush resistance, high cost, brittle nano-imprint template, etc., to achieve crush resistance The effect of good performance, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

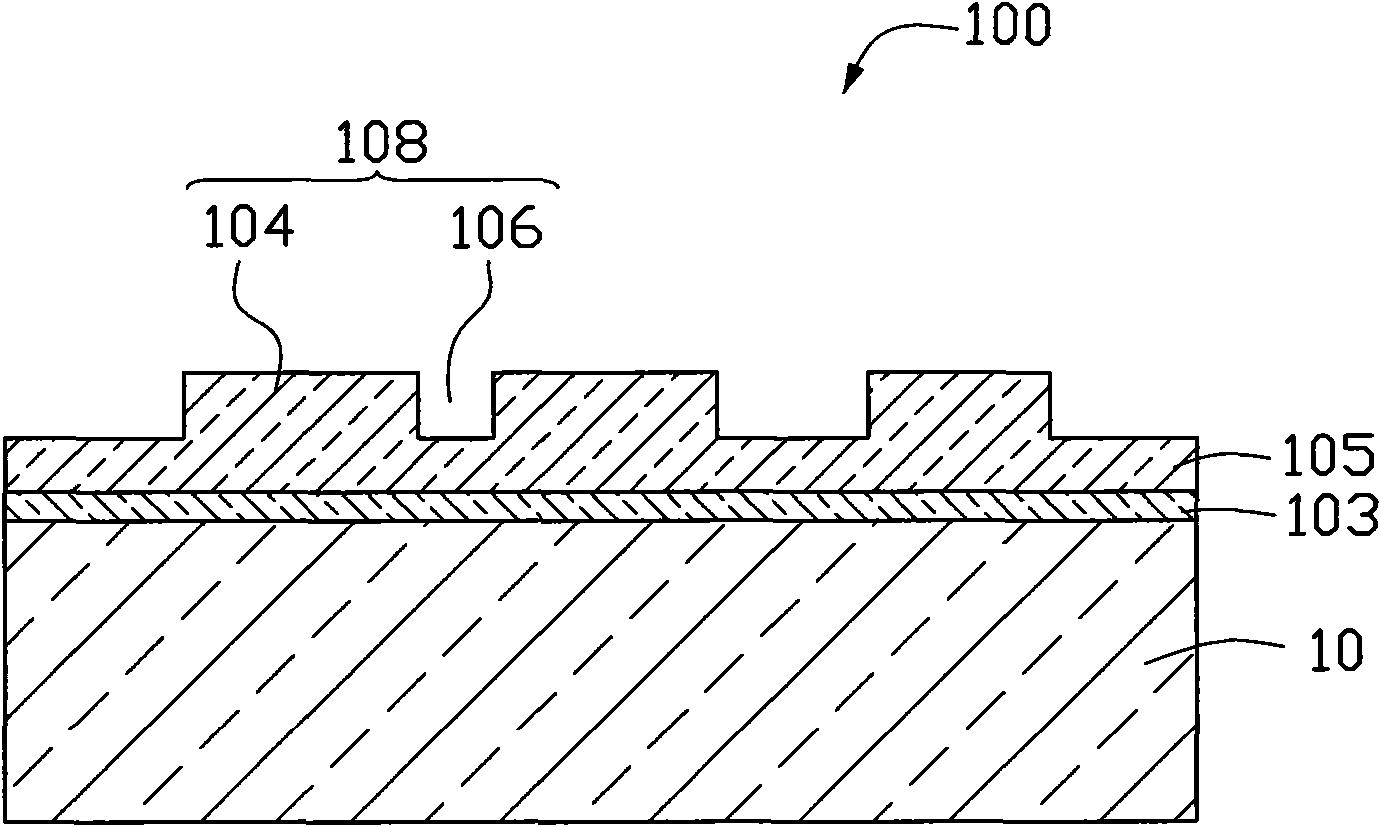

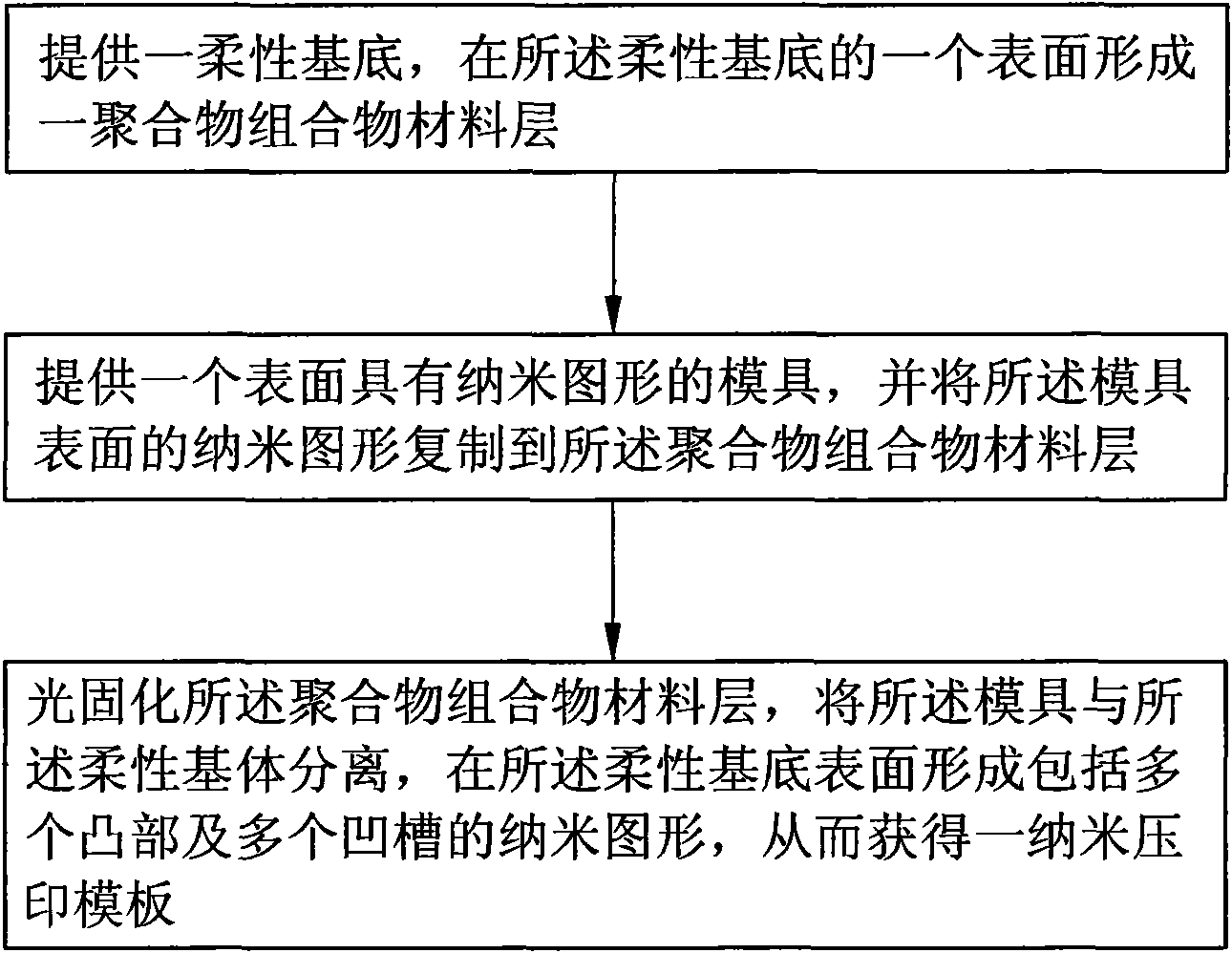

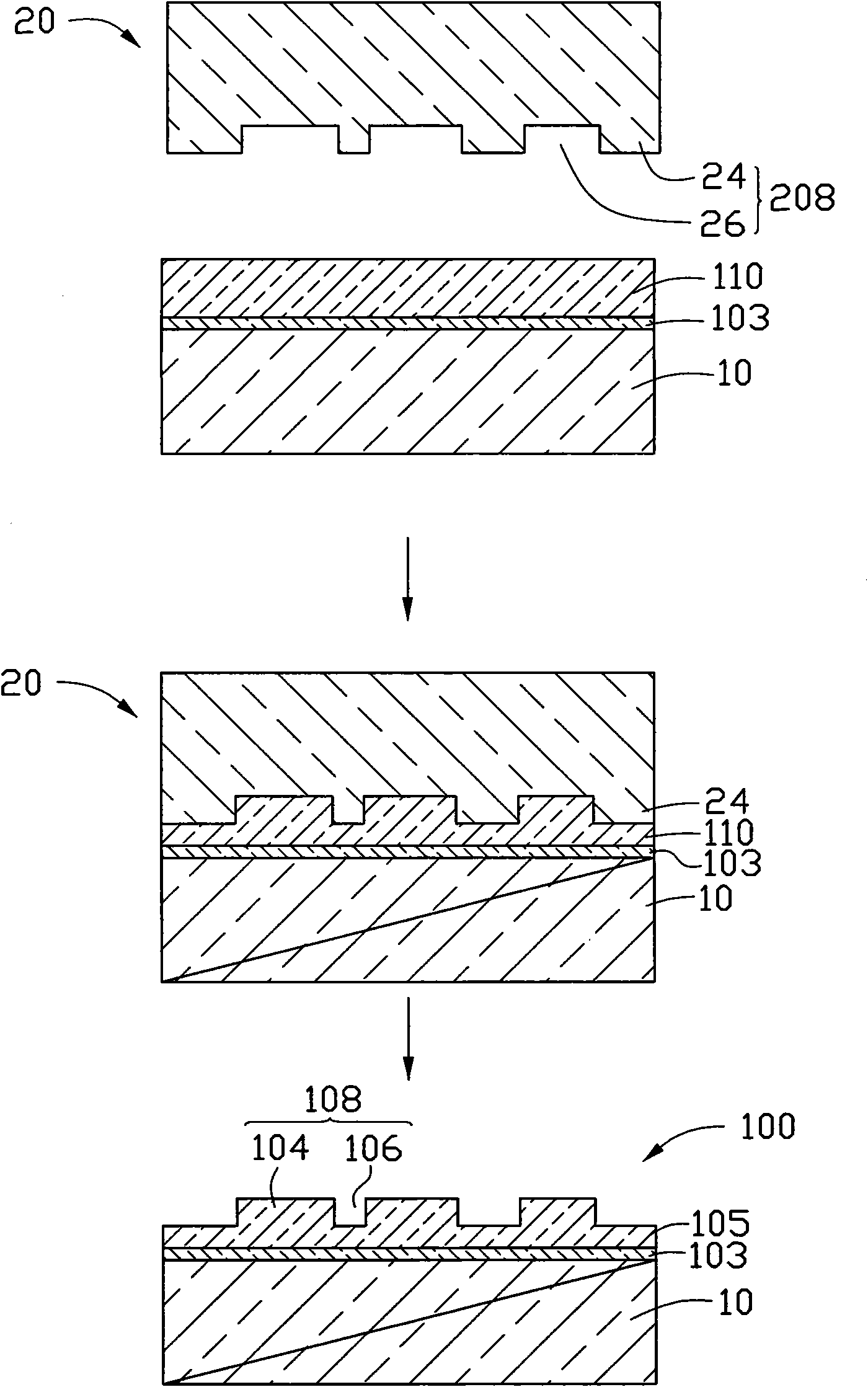

[0028] The present invention further provides a method for preparing the nanoimprint template. see figure 2 and image 3 , the first embodiment of the preparation method of the nanoimprint template includes the following steps:

[0029] In step 1, a flexible substrate 10 is provided, and a polymer composition material layer 110 is formed on one surface of the flexible substrate 10 .

[0030]The flexible base 10 is a flat plate, and its shape and size are not limited, and it can be a circular flat plate, a square flat plate, etc. The material of the flexible substrate 10 is a flexible transparent polymer material, specifically, it can be selected from silicone rubber, polyurethane, epoxy resin, polymethyl methacrylate, polyethylene terephthalate (PET) A blend of one and any of its components. In this embodiment, the flexible base 10 is a circular flat plate with the size of a 4-inch silicon wafer, and the material of the flexible base 10 is polyethylene terephthalate (PET)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com