New energy organosilicone pouring sealant with high thermal conductivity and low specific gravity

A silicone potting, high thermal conductivity technology, applied in adhesives, heat exchange materials, non-polymer adhesive additives, etc., can solve the problems of low adhesion, high hardness, low mechanical properties, etc., and achieve high Effects of thermal conductivity, low specific gravity, good handleability and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

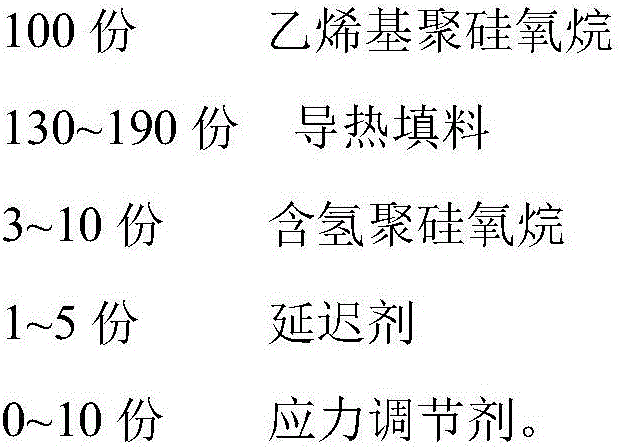

Method used

Image

Examples

Embodiment 1

[0028] Add 100 parts of dimethylvinylsiloxy-terminated dimethyl polysiloxane, 20 parts of modified spherical boron nitride, 10 parts of modified spherical magnesium oxide, 100 parts of modified silicon Micro powder, 50 parts of modified aluminum hydroxide, 3 parts of graphene, stirred and dispersed for 60 minutes at 120°C, -0.06Mpa. Add 10ppm platinum catalyst and stir to disperse evenly to make component A.

[0029] Add 100 parts of dimethylvinylsiloxy-terminated dimethyl polysiloxane, 20 parts of modified spherical boron nitride, 10 parts of modified spherical magnesium oxide, 100 parts of modified silicon Micropowder, 50 parts of modified aluminum hydroxide, 3 parts of graphene, stirred at 120°C and -0.06MPa for 60 minutes. Add 5 parts of hydrogen-containing polysiloxane to synthesize 2, 30ppm of benzotriazole, stir and disperse evenly, and make B component.

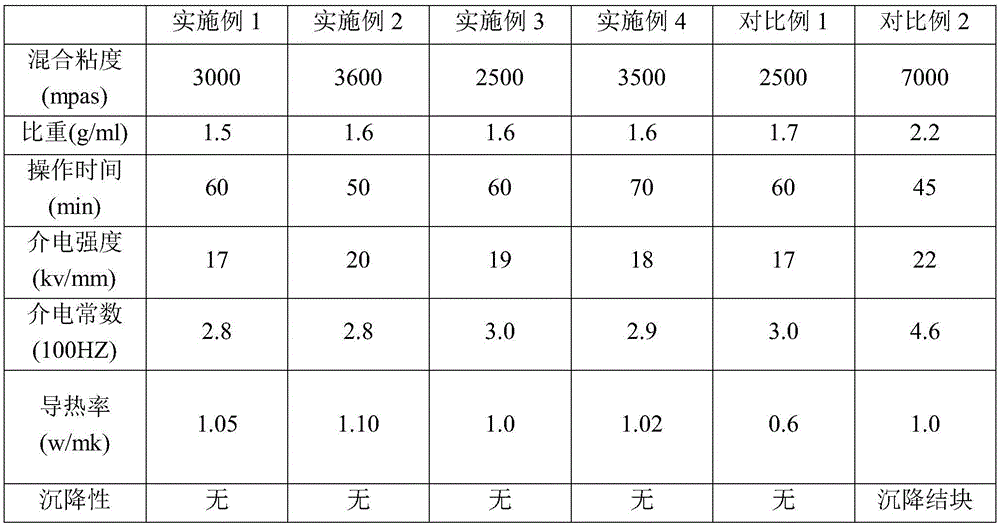

[0030] Mix components A and B according to the mass ratio of 1:1, and the test results are shown in Table 1.

Embodiment 2

[0032] Add 85 parts of dimethylvinylsiloxy-terminated dimethylpolysiloxane, 10 parts of dimethylvinylsiloxy-terminated methylvinylsiloxane and two Copolymer of methyl siloxane, 5 parts of modified spherical boron nitride, 20 parts of modified spherical magnesium oxide, 100 parts of modified silicon micropowder, 60 parts of modified aluminum hydroxide, 1 part of graphene, at 120 ° C, Stir for 40 minutes under the condition of -0.08Mpa. Cool to room temperature, stir and disperse the 10ppm platinum catalyst evenly to make component A.

[0033] Add 85 parts of dimethylvinylsiloxy-terminated dimethylpolysiloxane, 10 parts of dimethylvinylsiloxy-terminated methylvinylsiloxane and two Copolymer of methyl siloxane, 5 parts of modified spherical boron nitride, 20 parts of modified spherical magnesium oxide, 100 parts of modified silicon micropowder, 60 parts of modified aluminum hydroxide, 1 part of graphene, at 120 ° C, Stir for 40 minutes under the condition of -0.08Mpa. Add 2 pa...

Embodiment 3

[0036] Add 95 parts of dimethylvinylsiloxy terminated dimethylpolysiloxane, 15 parts of terminated trimethylvinylmethyl-dimethylsiloxane, 15 parts of 5 10 parts of modified graphene, 10 parts of modified spherical magnesium oxide, 10 parts of modified boron nitride, 100 parts of modified silicon micropowder, 60 parts of modified aluminum hydroxide, stirred for 40 minutes at 120 ° C, -0.08Mpa . Cool to room temperature, stir and disperse the 10ppm platinum catalyst evenly to make component A.

[0037] Add 100 parts of dimethylvinylsiloxy-terminated dimethyl polysiloxane, 10 parts of 15 parts of terminated trimethylvinylmethyl-dimethylsiloxane, 5 parts in a planetary mixer 10 parts of modified graphene, 10 parts of modified spherical magnesium oxide, 10 parts of modified boron nitride, 100 parts of modified silicon micropowder, 60 parts of modified aluminum hydroxide, stirred for 40 minutes at 120 ° C, -0.08Mpa . Add 2 parts of hydrogen-containing polysiloxane to synthesize 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com