Light liquid crystal polyester resin compound and preparation method thereof

A technology of resin compound and liquid crystal polyester, which is applied in the field of light liquid crystal polyester resin compound and its preparation, can solve the problems of large specificity of liquid crystal polyester resin and affect the weight reduction of electronic parts, so as to improve compatibility, Low specific gravity characteristics, effects of improving heat resistance and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] On the other hand, the embodiment of the present invention also provides a preparation method of the light liquid crystal polyester resin compound of the embodiment of the present invention described above. In one embodiment, the preparation method of the light liquid crystal polyester resin compound of the embodiment of the present invention includes the following steps:

[0046] S01. According to the components contained in the light-weight liquid crystal polyester resin compound described in the embodiments of the invention above, the raw materials of each component are weighed respectively;

[0047] S02. Drying the weighed liquid crystal polyester resin, additives, first filler, and second filler;

[0048] S03. Mixing the dried liquid crystal polyester resin, first filler, second filler, and additive to obtain a mixed material;

[0049] S04. Melting and extruding the mixed material.

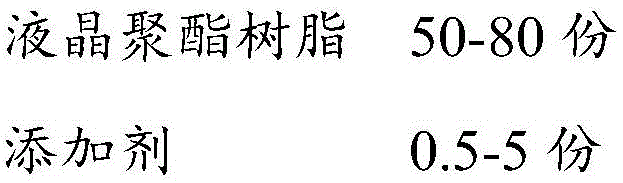

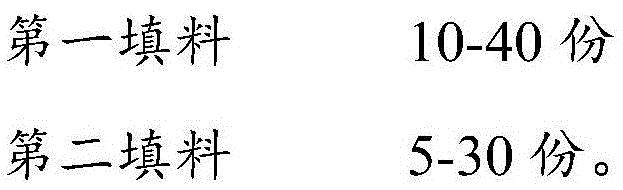

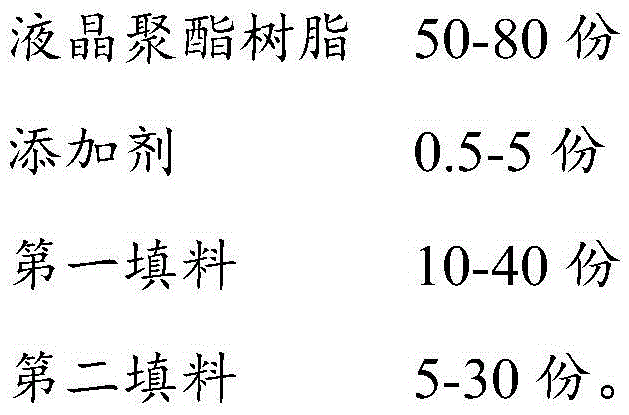

[0050] Specifically, in the above-mentioned step S01, the components of the liqu...

Embodiment 1

[0061] This embodiment provides a light-weight liquid crystal polyester resin compound with low specific gravity and a preparation method thereof. Among them, the components of the lightweight liquid crystal polyester resin compound are: 64.5 parts of fully aromatic liquid crystal polyester resin (Jiangsu Water Special Material Manufacturing Co., Ltd.), 0.5 parts of dodecylphenyl POSS, 25 parts of glass fiber, talc Powder 10 parts.

[0062] The preparation method of the lightweight liquid crystal polyester resin compound is as follows:

[0063] S11. according to the ratio in the following table 1, the whole aromatic liquid crystal polyester resin, dodecaphenyl POSS, glass fiber and talcum powder are dried;

[0064] S12. Put the dried wholly aromatic liquid crystal polyester resin, glass fiber, talcum powder, and dodecaphenyl POSS into an automatic mixer for uniform mixing to obtain a mixed material;

[0065] S13. Putting the mixed material into a twin-screw extruder for melt...

Embodiment 2

[0067] The proportions by weight of the wholly aromatic liquid crystal polyester resin, dodecaphenyl POSS, glass fiber, and talcum powder selected in Example 1 were changed to 64:1:25:10, as shown in Table 1. Except for this, a wholly aromatic liquid crystal polyester resin composite was produced in exactly the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com