Composite dielectric material, copper-clad foil prepreg manufactured and copper-clad foil laminated board by using composite dielectric material

A technology for copper clad laminates and dielectric materials, applied in the field of copper clad laminates, can solve the problems of poor heat resistance, heat resistance cannot meet high heat resistance, etc., and achieves simple processing methods and good processability. , the effect of high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

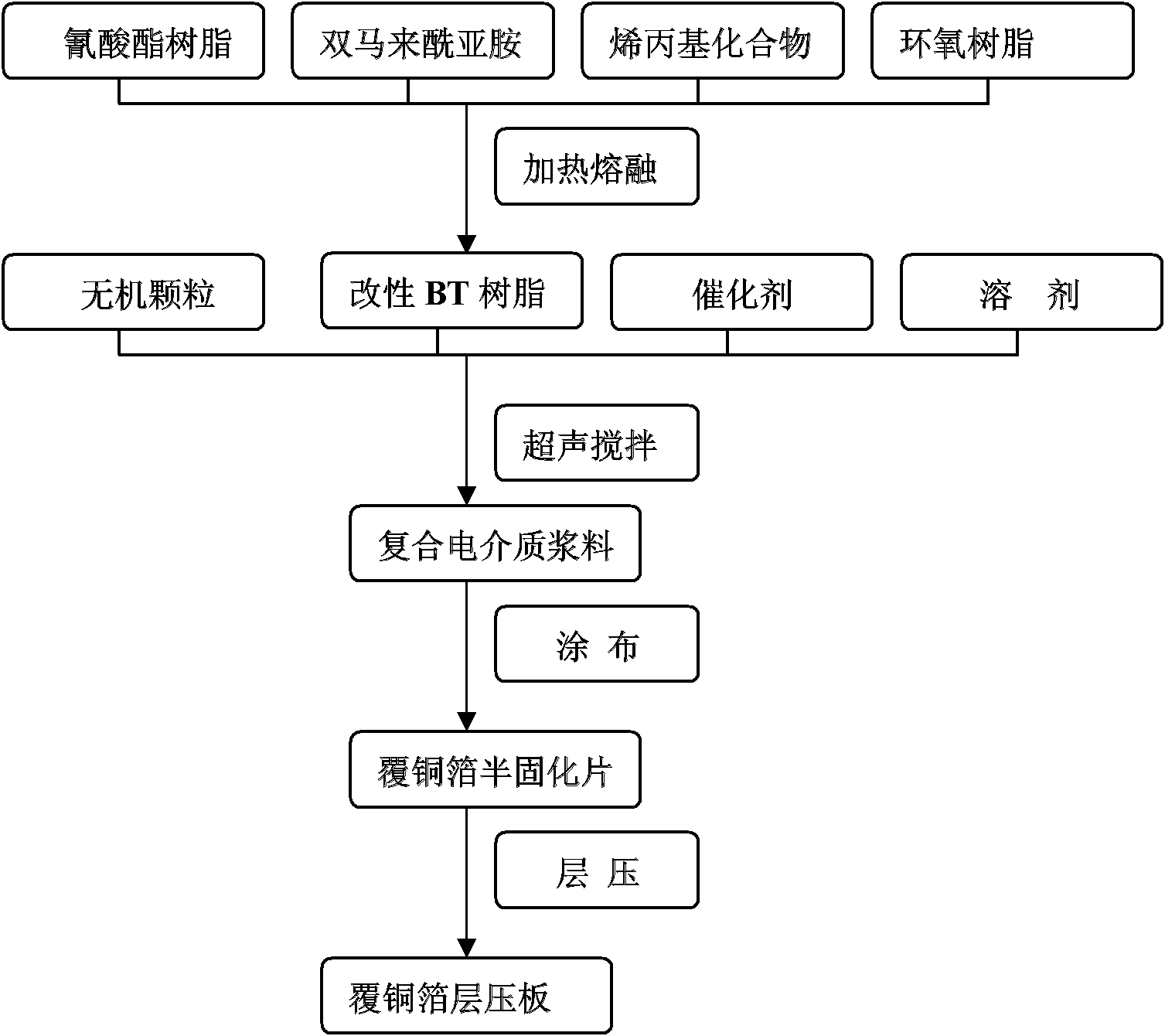

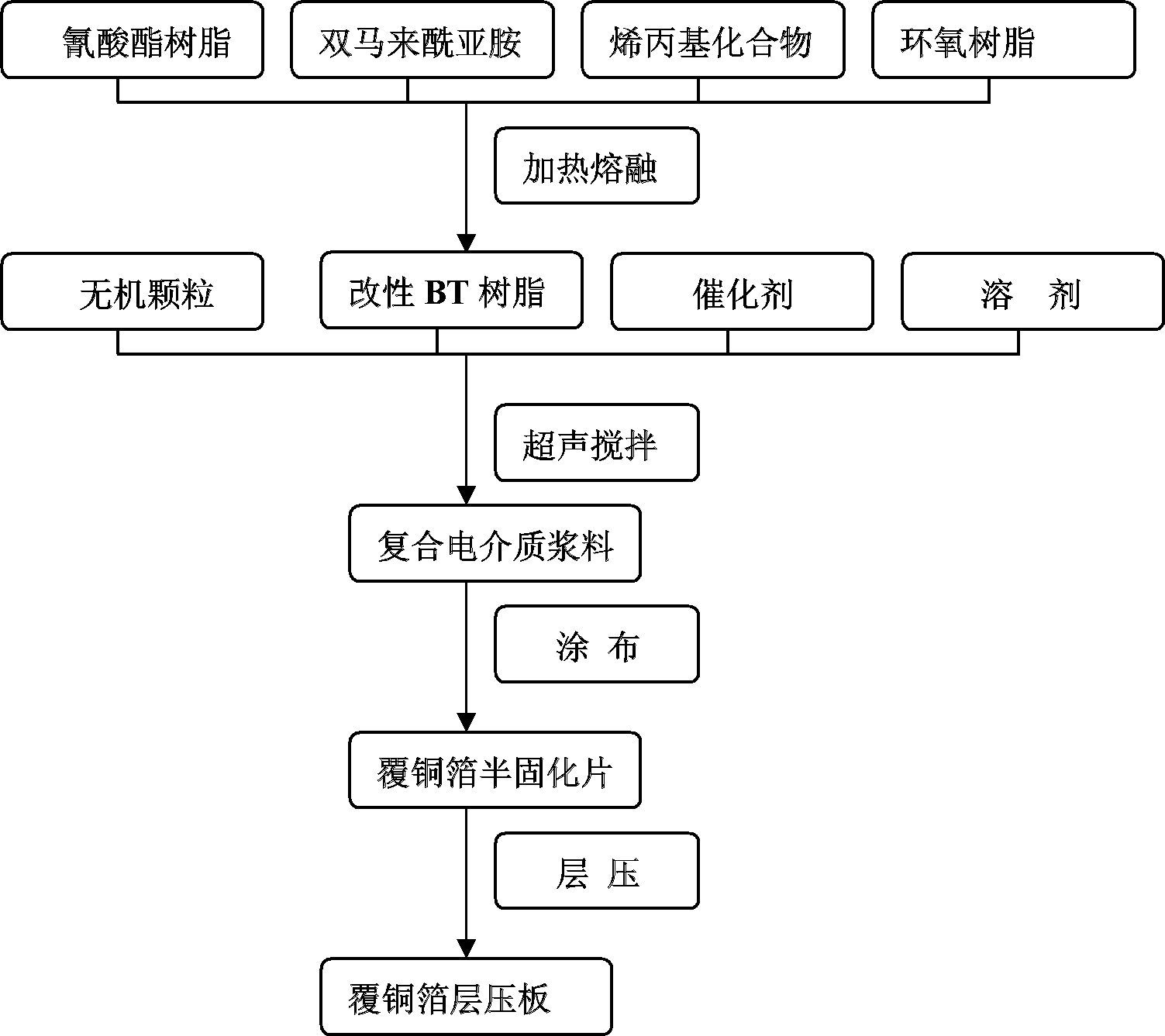

[0045] A kind of composite dielectric material of the present invention, the prepreg that adopts it to make and copper-clad laminated board production process are as follows figure 1 shown. The specific steps are as follows:

[0046] Step 1: BT Resin / BaTiO 3 Preparation of composite dielectric materials

[0047] Weigh 70g of BaTiO with a particle size of 100nm after high temperature treatment at 350°C 3 The particles were added to 7g of 3-(2,3-glycidoxy)propyltrimethoxysilane (KH-560) and 200mL of butanone solvent, stirred and ultrasonically oscillated for 12 hours at 70°C, and then the solution was Heating while stirring until the solvent volatilized completely, the modified BaTiO 3 The particles are dried and ground for later use.

[0048] With 50g bisphenol A type cyanate ester, 30g diphenylmethane type bismaleimide, 10g 2,2'-diallyl bisphenol A and 10g bisphenol A type epoxy resin (E-44) in Stir and mix evenly at 120°C, and maintain this temperature for 30 minutes to...

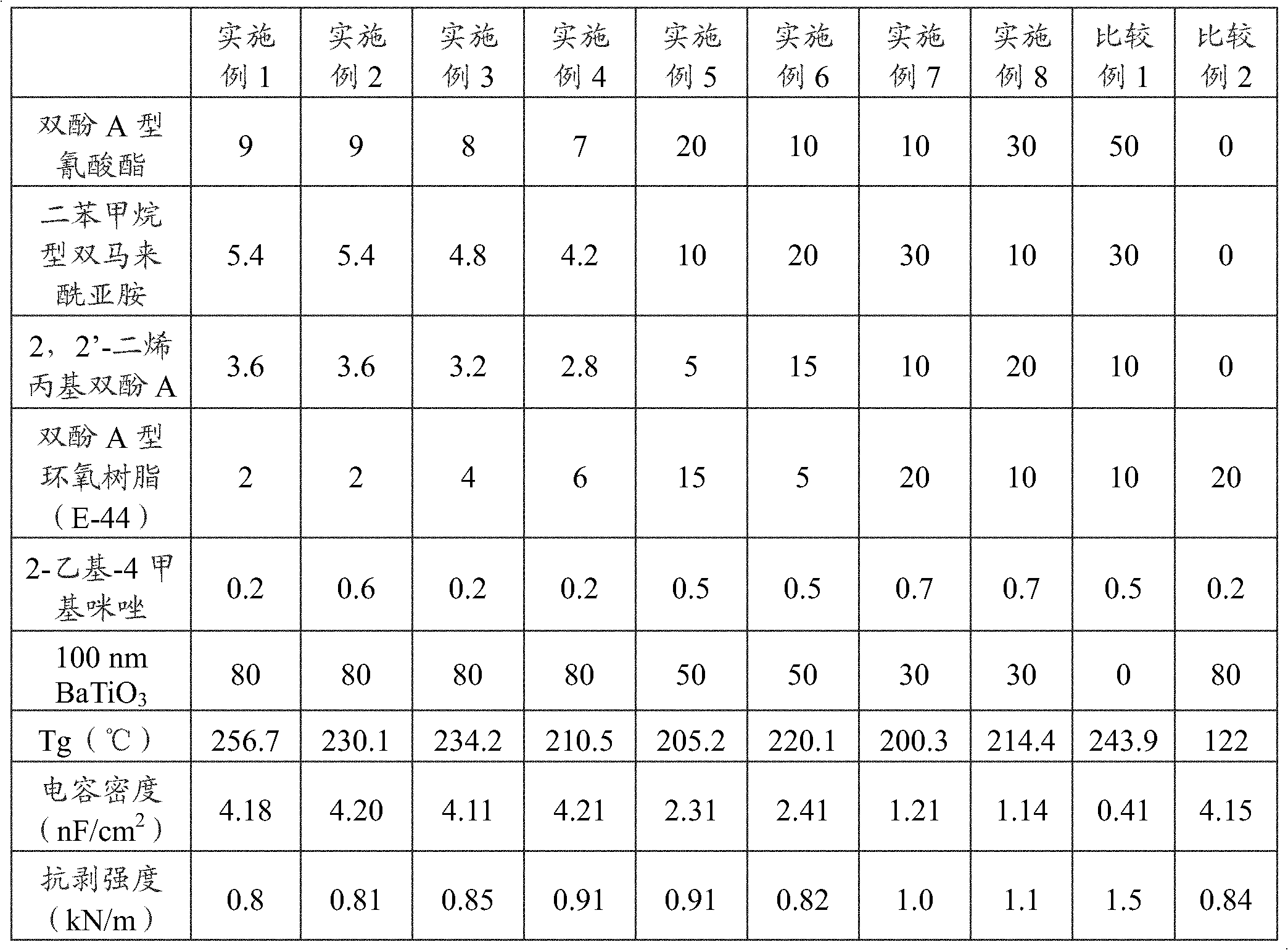

Embodiment 2-8

[0055] According to the same preparation method as described in Example 1, the difference is that the amount of each component is the amount shown in Table 1. The unit of each group consumption in Table 1 is parts by weight.

Embodiment 9

[0062] Step 1: Preparation of BT resin / aluminum composite dielectric material

[0063] Disperse 80g of nano-aluminum powder in absolute ethanol dissolved in polyethylene glycol (PEG-6000), and disperse in an ultrasonic generator for 120 minutes before use. In the four-neck bottle, add pretreated nano-aluminum powder suspension 70g, styrene monomer 30g, initiator AIBN 3g, dispersion stabilizer PVP 0.5g and reaction medium in order, and initiate dispersion polymerization reaction under nitrogen protection. It was reacted at 70°C for 24h. After the reaction, the sample was subjected to centrifugal sedimentation in an ultra-high-speed centrifuge, and the lower layer of particles was repeatedly washed with absolute ethanol. The washed lower particles were extracted with acetone for 24 hours, poured into a petri dish, and vacuum-dried at low temperature to obtain polystyrene-coated nano-aluminum powder.

[0064]With 50g bisphenol A type cyanate ester, 30g diphenylmethane type bism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Capacitance density | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com